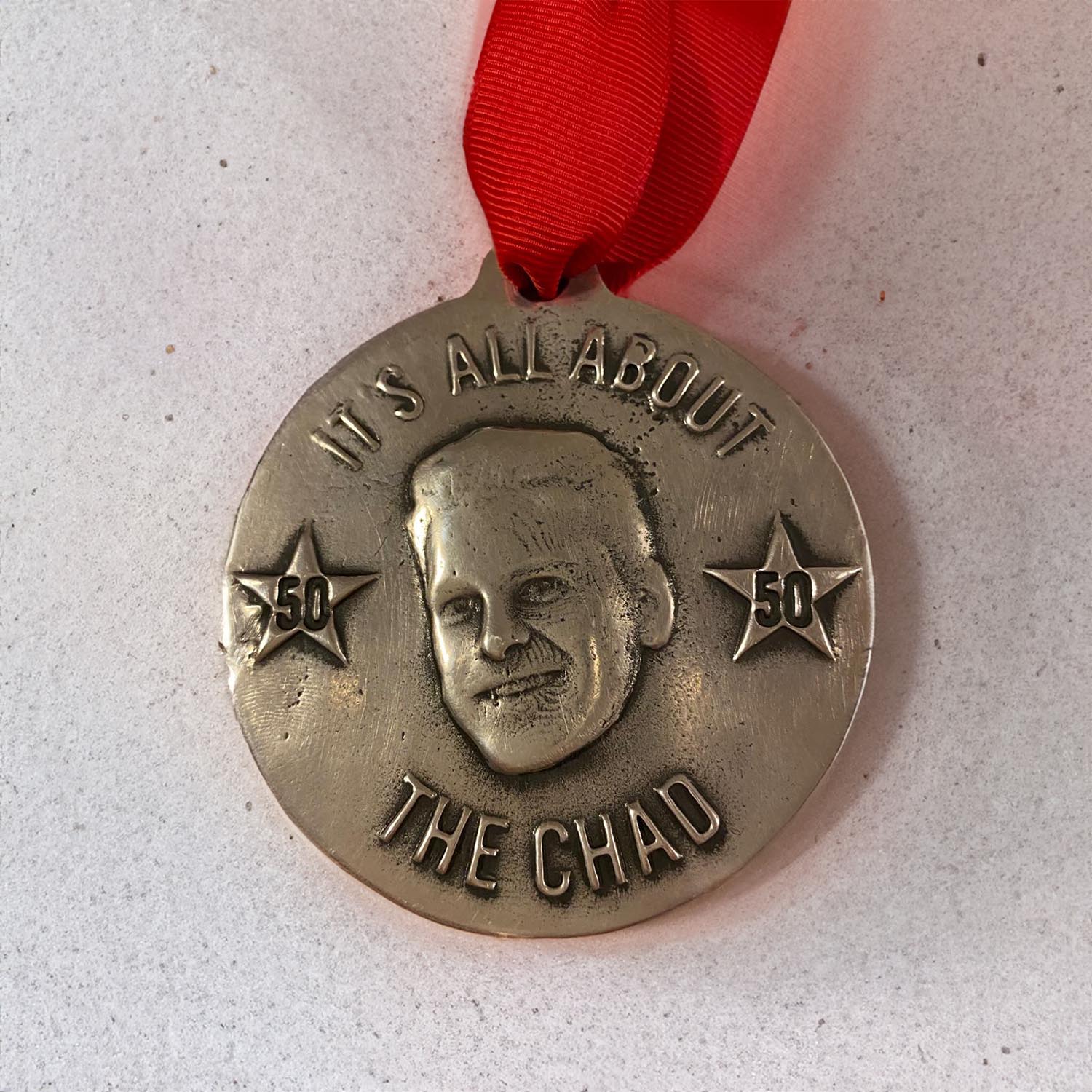

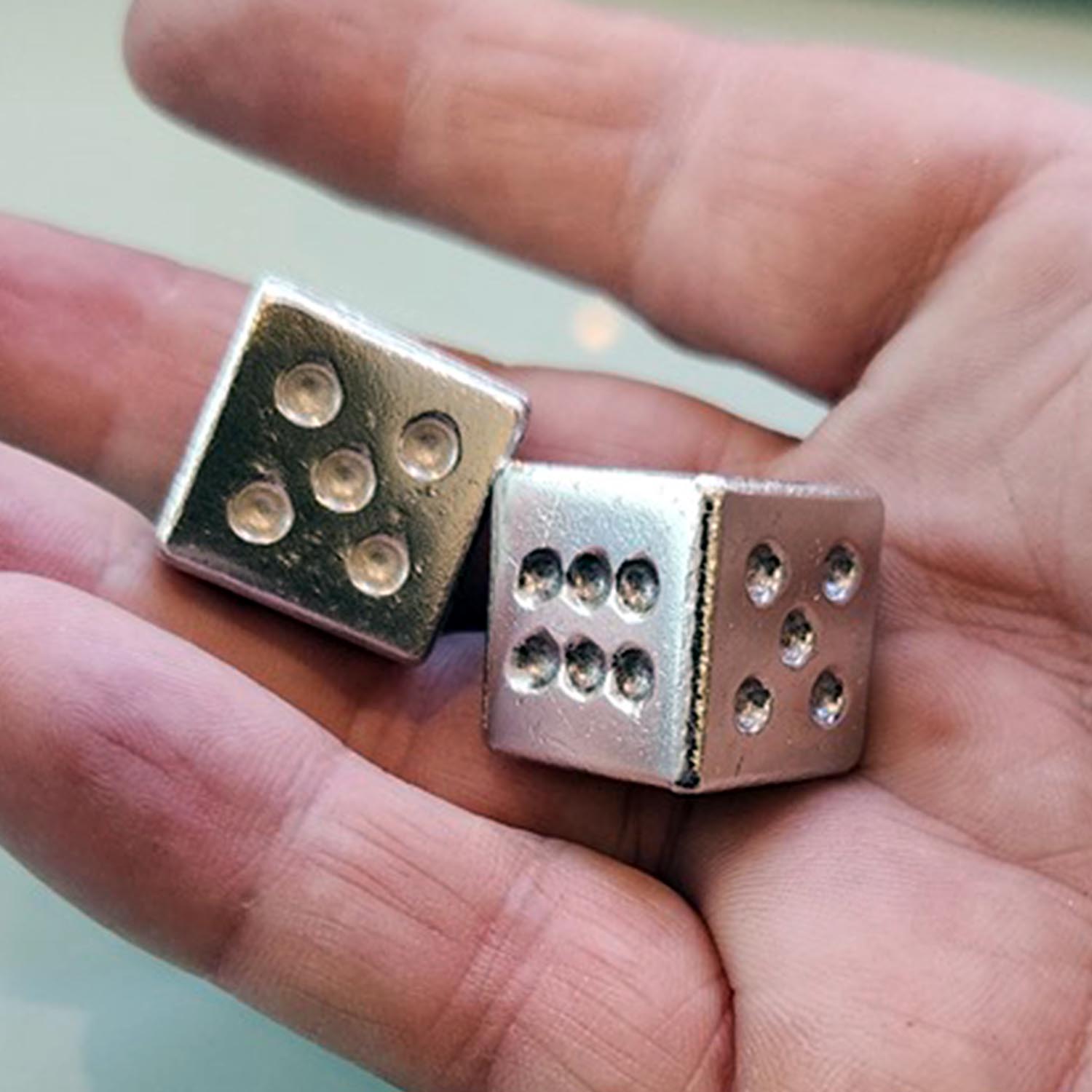

COINS | DIE-CAST TOYS | SCALE MODEL PARTS | AUTOMOTIVE PARTS | HARDWARE | SOUVENIRS | DECORATIVE ITEMS | TROPHIES AND AWARDS | CLOCK PARTS | MINIATURES | JEWELLERY | ELECTRICAL COMPONENTS

ThermaCAST™ | Product Overview

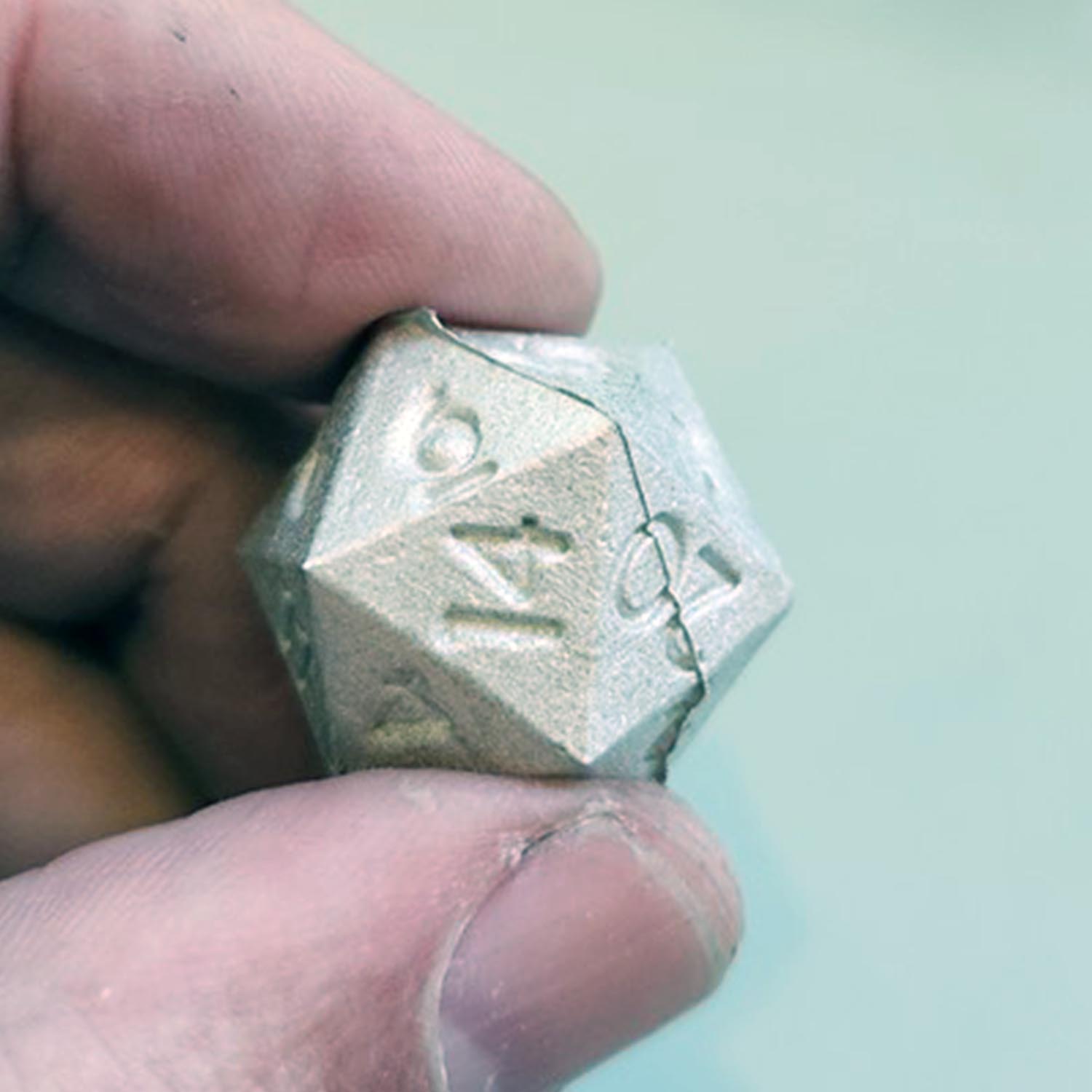

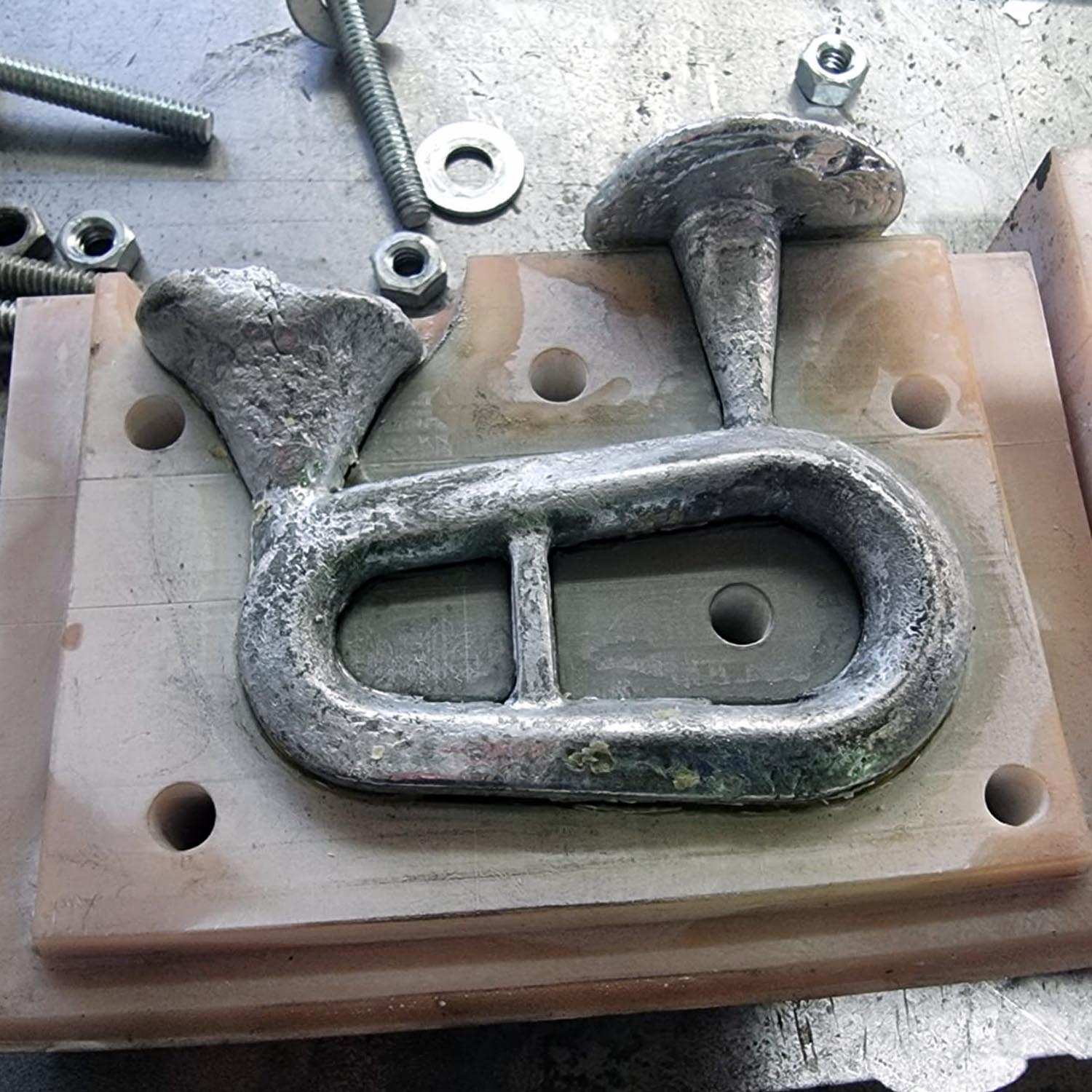

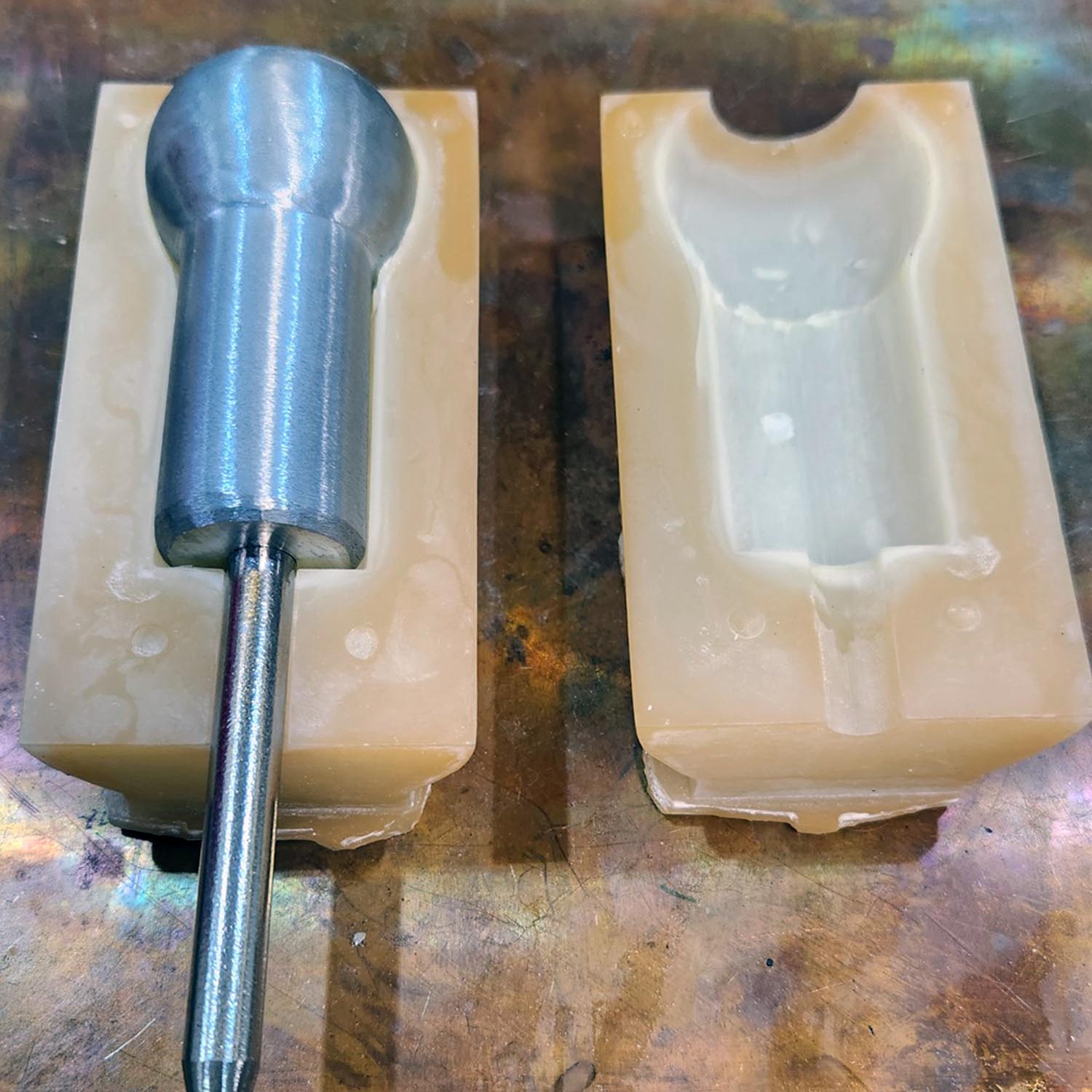

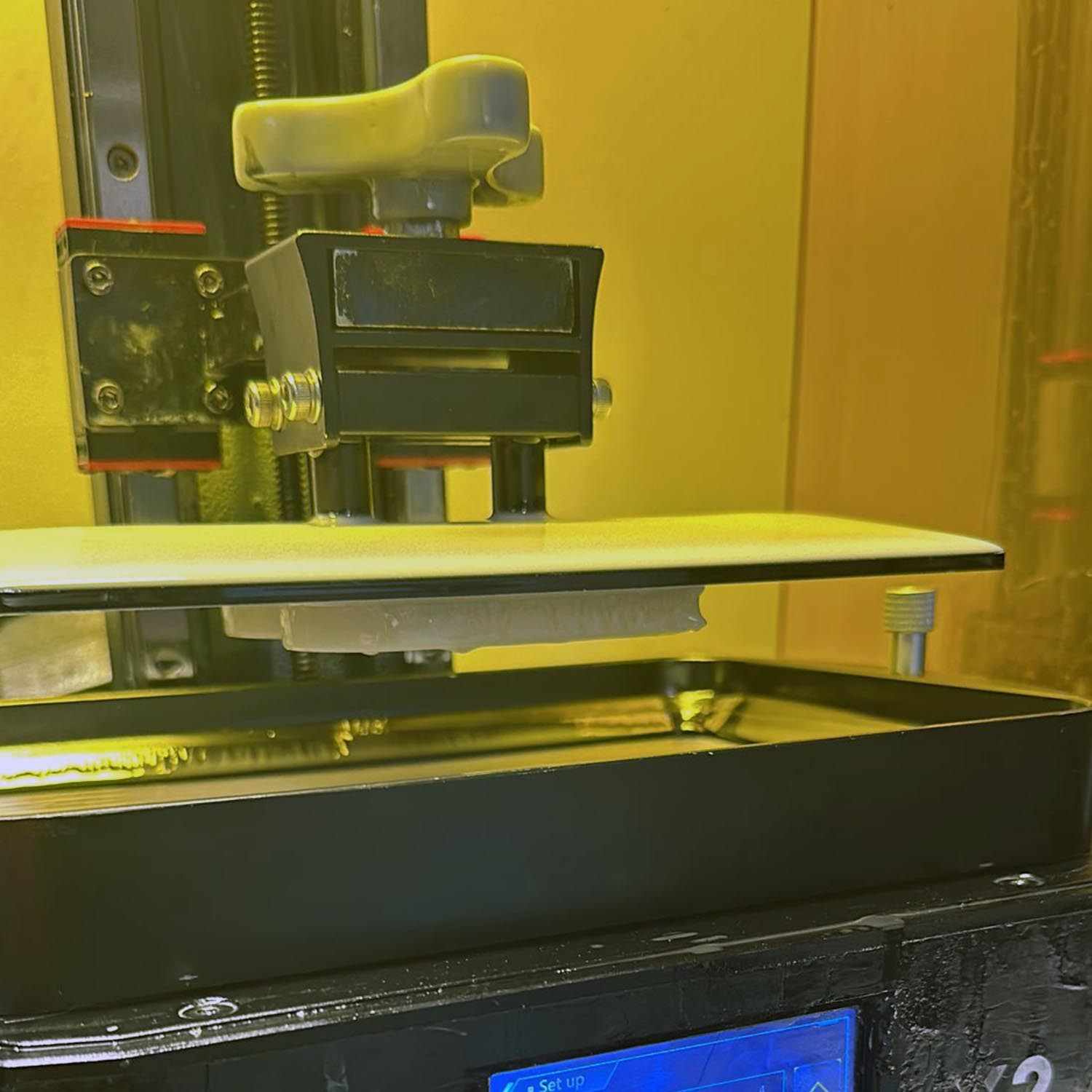

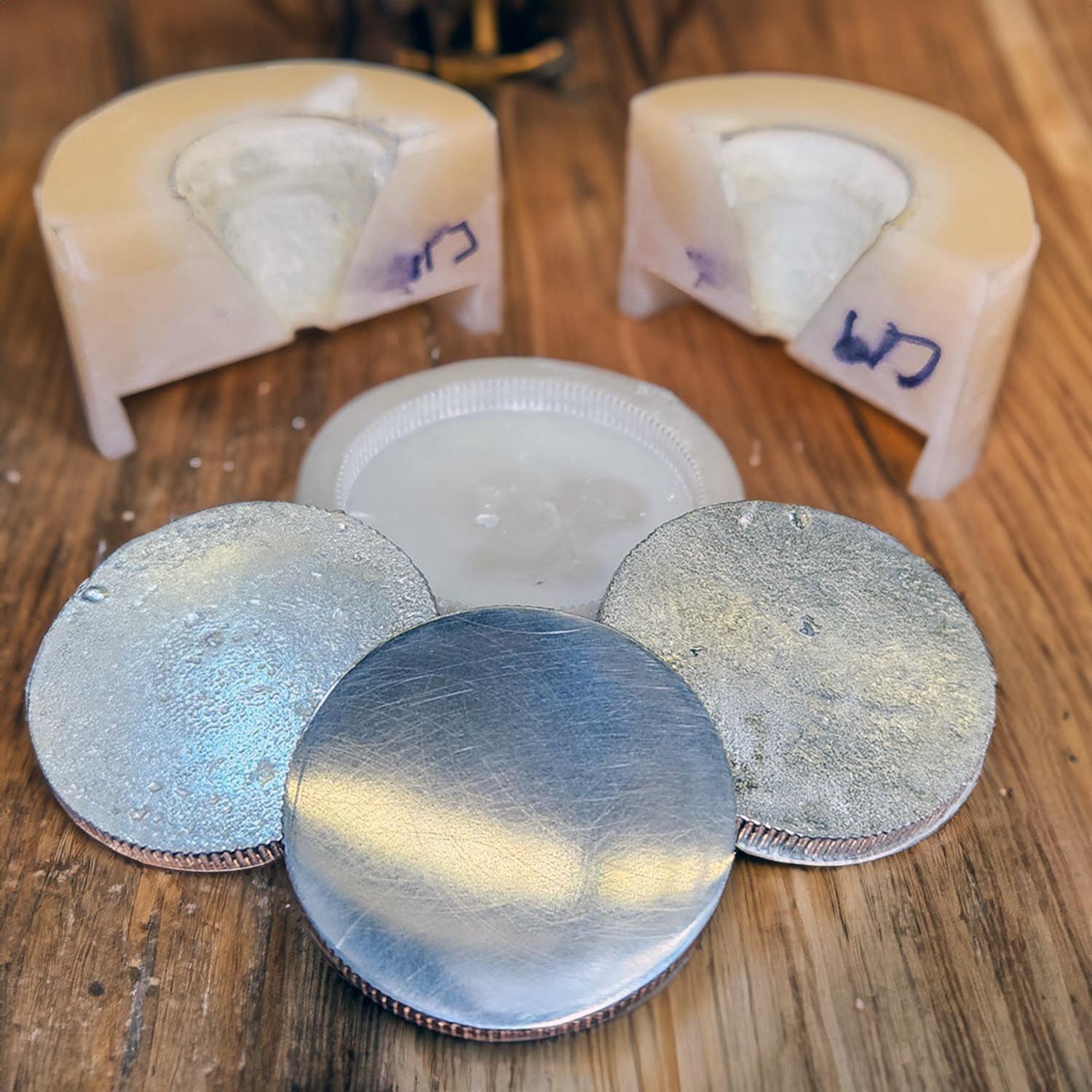

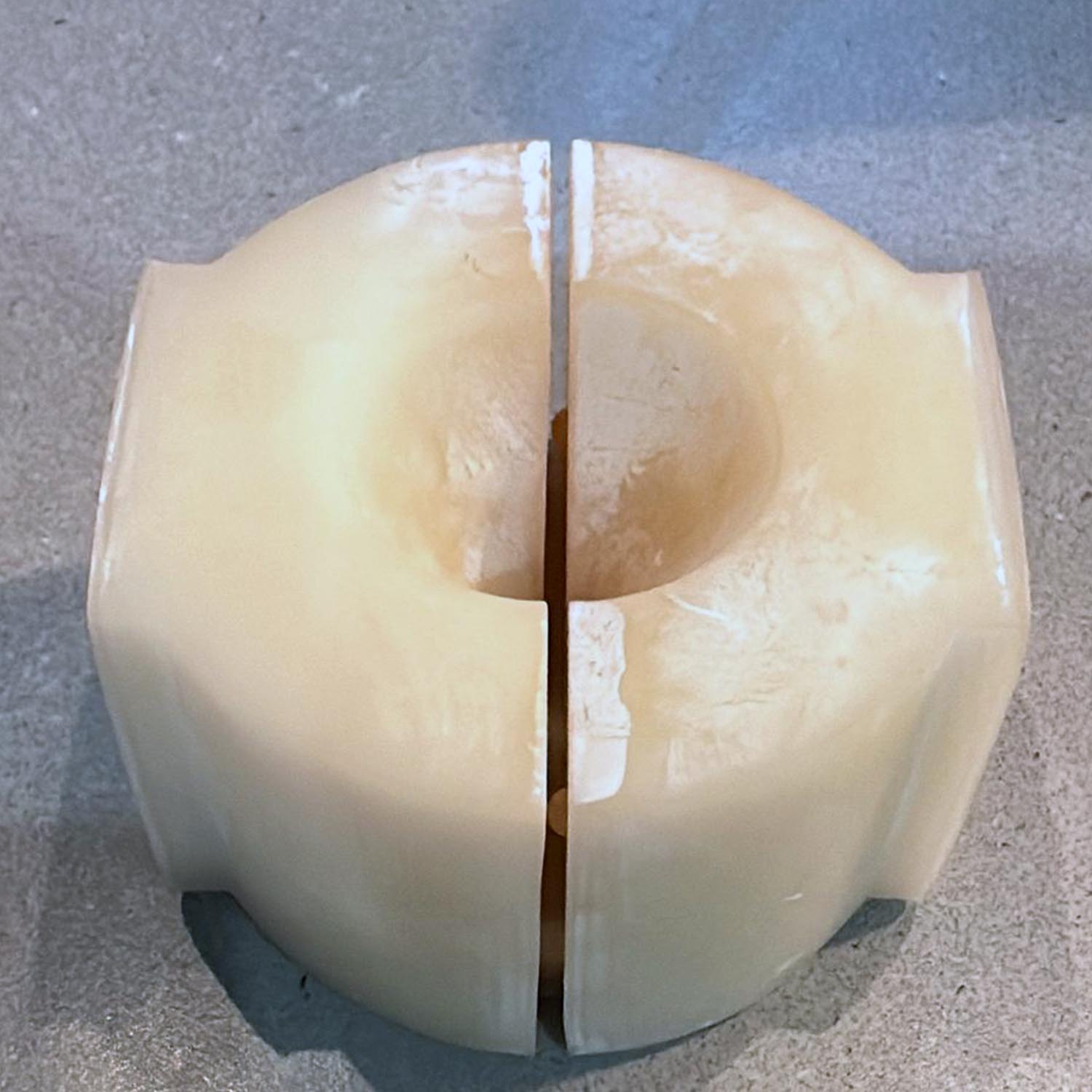

Monocure3D developed ThermaCAST™ to 3D-print reusable moulds for the casting of metal alloys. Compatible with most resin 3D printers, ThermaCAST™ allows designers, engineers, manufacturers, and hobbyists to produce high-quality, detailed metal parts quickly and affordably.

This resin is ideal for various applications, including jewellery, scale models, custom components, automotive and machinery parts, hardware, processing equipment, and tools. Whether manufacturing functional industrial components or detailed scale models, a reusable 3D-printed mould using ThermaCAST™ allows the casting of metal parts at a fraction of the time and cost compared to traditional methods.

By eliminating the need for expensive casting methods such as CNC-routed moulds, silicon pads, and messy sand casting, ThermaCAST™ streamlines the alloy casting process. Anyone with a standard desktop MSLA 3D printer, a low-cost furnace (optional for low-temperature metals like pewter), basic safety equipment, and ThermaCAST™ resin can create metal parts with precision, consistency and ease.

ThermaCAST™ | Key Features and Benefits

Superior Thermal Properties

Effectively manages direct surface heat, minimising heat transfer that could damage the mould.

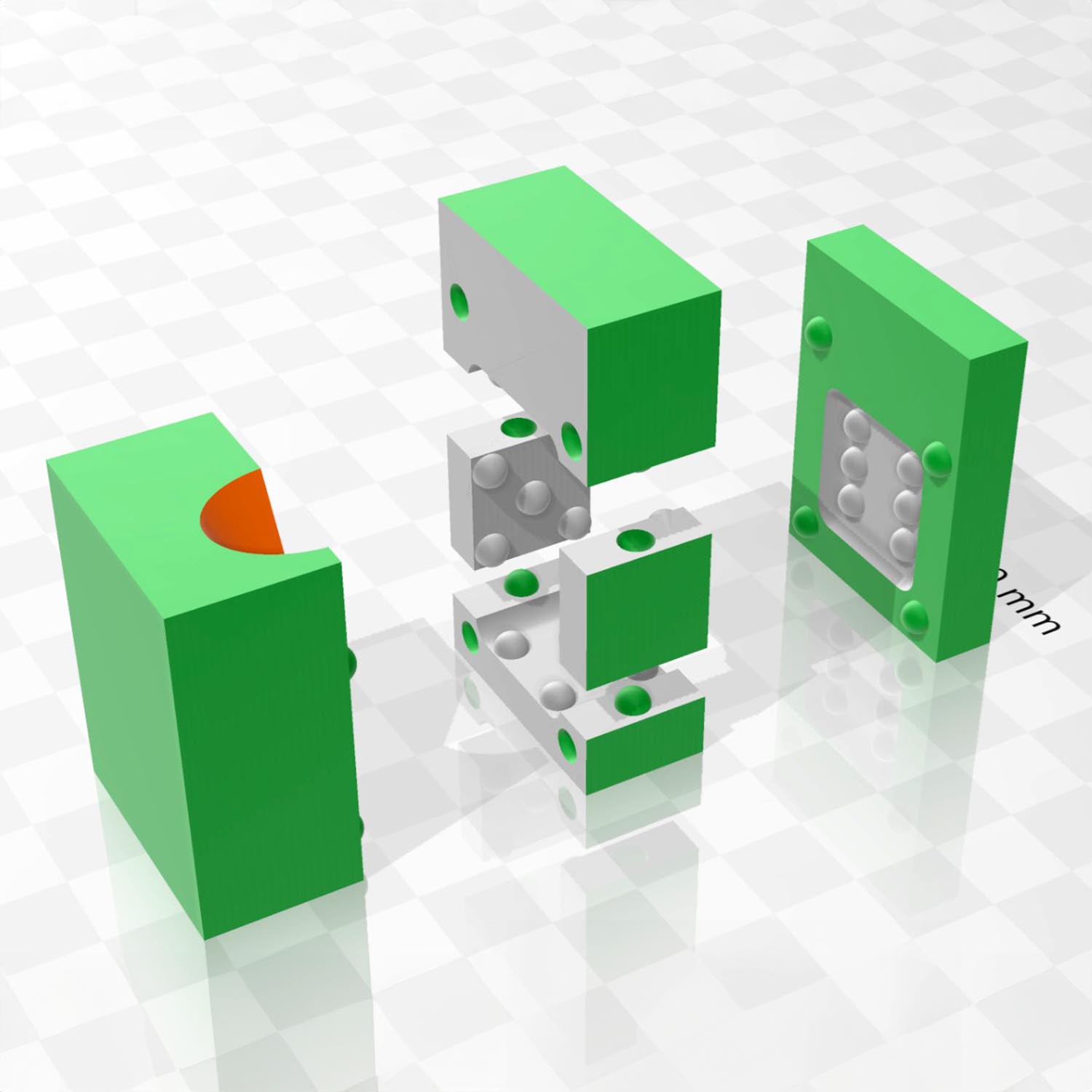

16K High-Precision and Fine Details

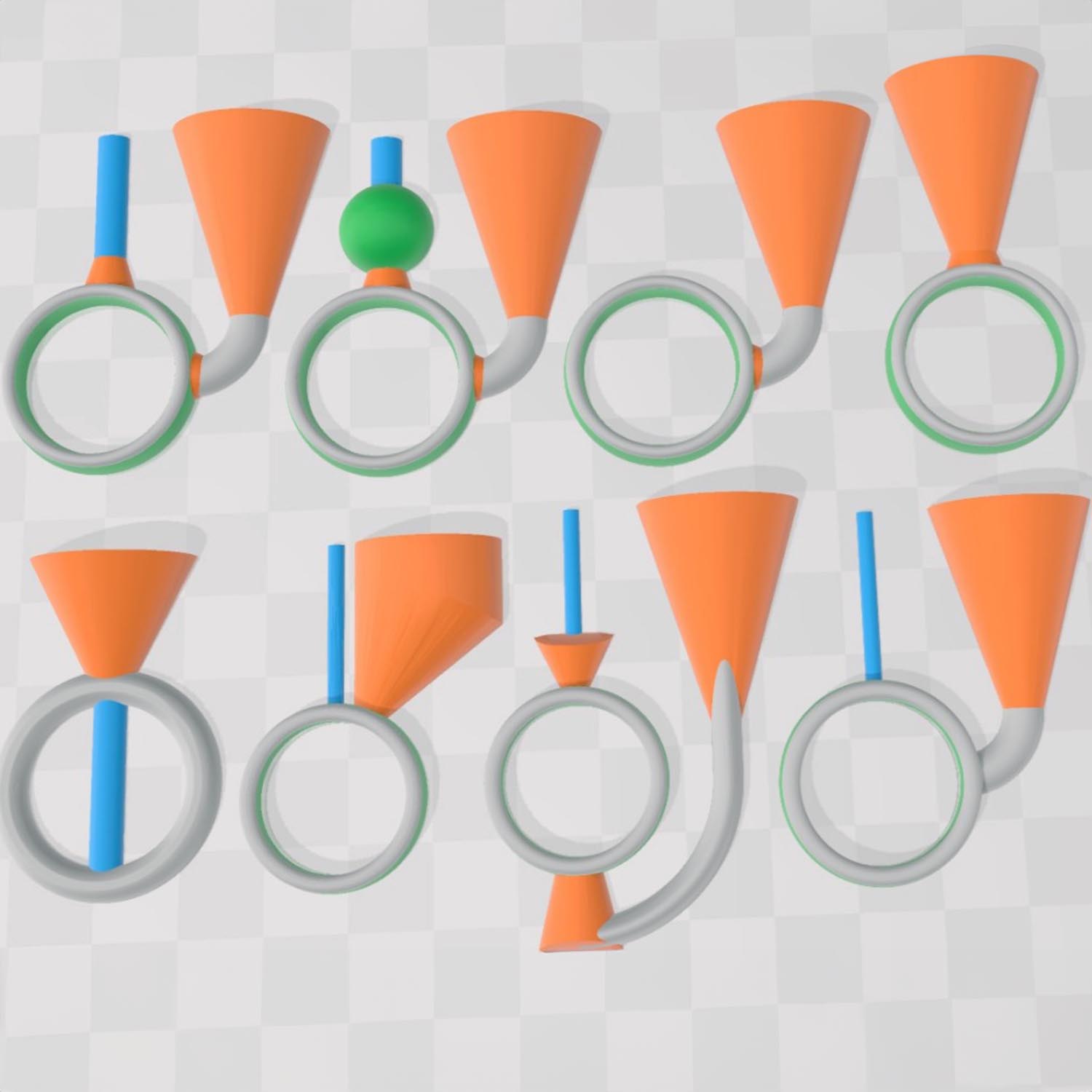

It enables the creation of intricate and detailed moulds, perfect for complex designs and fine features in cast parts.

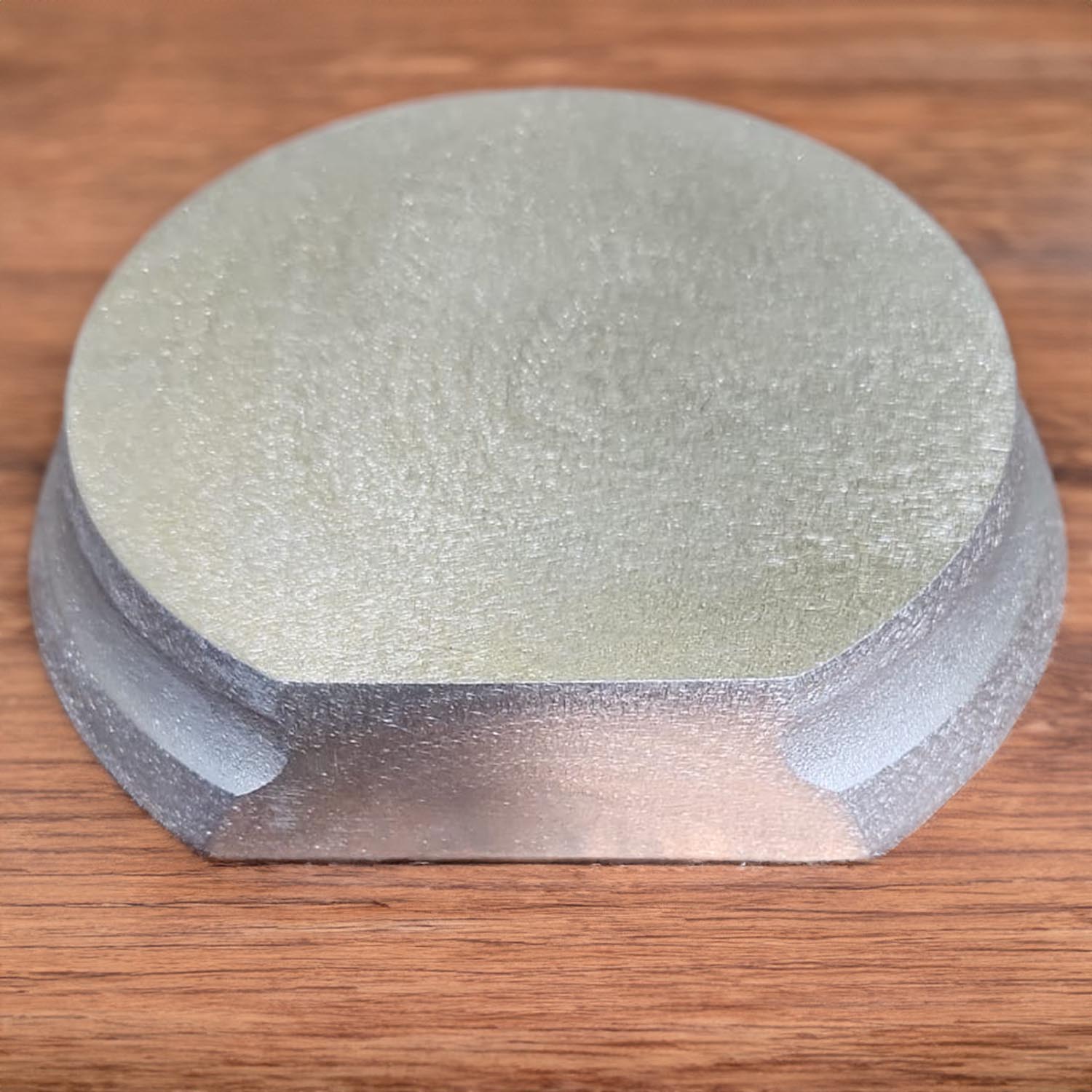

Durable Mold Construction

To ensure longevity and the ability to withstand repeated use, the mould walls only have to be 5-8mm thick.

User-Friendly & Affordable

Simplifies the casting workflow with clear guidelines and support, allowing anyone to make metal parts.

ThermaCAST™ | 3D Printing Meets Metal Casting

ThermaCAST™ delivers advanced high-temperature capabilities tailored for direct metal casting. Capable of withstanding temperatures up to 550°C*, this resin is the perfect solution for creating intricate and durable metal parts directly from your MSLA 3D printer. This material ensures exceptional durability, precision, and heat resistance, providing reliable and high-quality castings across various applications and materials.

The future of metal casting is here! ThermaCAST™ removes the complexities associated with traditional casting methods. Compared to using heat-resistant silicons, 2-part resins, pads (used in spin casting), messy sand casting, injection moulding, and the complicated investment casting process, you can save time and money creating moulds. This streamlined approach enhances accessibility and efficiency for professionals and hobbyists, transforming the way metal casting is approached.

ThermaCAST™ | The Quick Start Guide

(Use the Arrows to Scroll through the Steps)

ThermaCAST™ Applications & Considerations

Versatility and Application

ThermaCAST is suitable for various industrial uses, from automotive and aerospace components to intricate jewellery and artistic pieces. Its high-temperature tolerance makes it a versatile choice for various casting applications, ensuring that ThermaCAST delivers consistent, high-quality results no matter the project.

Advanced Formulation

ThermaCAST’s advanced formulation includes additives that enhance its performance under high temperatures. These ensure that the resin does not crack, split, or exhibit surface issues during the casting process, making it a reliable choice for professionals seeking a high-performance casting resin.

Ease of Use

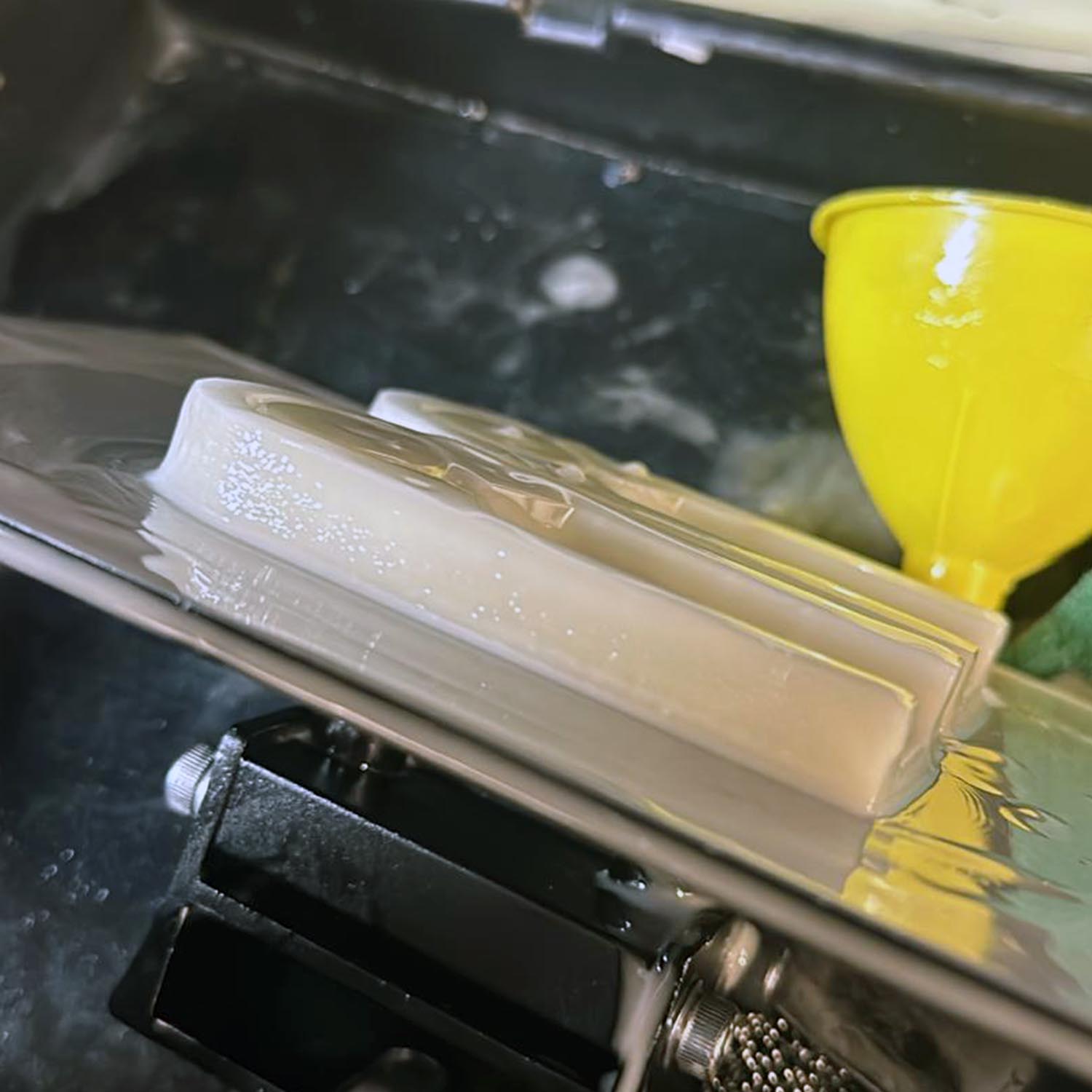

ThermaCAST is designed with user convenience in mind. The resin is easy to handle and can be processed using standard 3D printing equipment. Detailed instructions are provided to ensure optimal results, from preparing the environment and adjusting print settings to post-print cleaning and curing.

Compatible Metal Information

Here are some metals that can be cast at temperatures under 500°C:

1. Pewter: is a low-melting-point alloy, typically consisting of tin mixed with small amounts of other metals like copper, antimony, bismuth, or lead. It melts around 170-230°C, making it ideal for low-temperature casting.

2. Tin: has a melting point of around 232°C. It’s often used in casting for applications like figurines, medals, and small parts.

3. Lead: melts at about 327°C. It’s commonly used for casting fishing weights, bullets, and other applications where its density is advantageous.

4. Zinc: Its melting point is approximately 419°C, but it can be alloyed with other metals to lower it. Zinc alloys are frequently used in die casting for small components.

5. Bismuth: Melts at about 271°C. It is often used in low-melting-point alloys for safety devices like fire sprinkler systems and metalworking applications.

6. Cadmium: Although not commonly used due to toxicity concerns, cadmium melts at around 321°C. It’s sometimes found in certain low-melting-point alloys.

7. Indium: Indium has a melting point of 156°C. It’s used in some specialty low-melting-point alloys and for applications requiring soft, malleable metals.

8. Field’s Metal: This is a fusible alloy consisting of bismuth, indium, and tin, with a melting point of approximately 62°C. It’s often used in demonstrations and for creating fusible plugs in safety devices.

9. Wood’s Metal: Another fusible alloy with a melting point around 70°C, composed of bismuth, lead, tin, and cadmium. It’s used in similar applications to Field’s Metal.

10. Rose’s Metal: Melting at around 98°C, this alloy of bismuth, lead, and tin is used for similar applications where low melting points are advantageous.

Metal Melting and Pouring Temperatures Guide

The table below shows temperature ranges for low-melting-point metals ideal for ThermaCAST™ Resin moulds. Optimal casting temperatures are typically 50–100°C (122–212°F) above the melting point, depending on mould size, detail, and shape. These metals are commonly used for jewellery, custom components, and small-scale manufacturing.

| Metal | Melting Temperature (°C) | Melting Temperature (°F) | Optimal Pouring Temperature (°C) | Optimal Pouring Temperature (°F) |

|---|---|---|---|---|

| Pewter | 170–230 | 338–446 | 280–300 | 536–572 |

| Tin | 232 | 450 | 280–300 | 536–572 |

| Bismuth | 271 | 520 | 300–320 | 572–608 |

| Lead-Free Solder | 217–227 | 423–441 | 250–270 | 482–518 |

| White Metal | 200–250 | 392–482 | 280–300 | 536–572 |

| Zinc | 420 | 788 | 480–510 | 896–950 |

| Zinc Alloy (ZA12) | 432 | 810 | 480–500 | 896–932 |

| Zinc Alloy (ZA 3/5) | 386 | 727 | 430–450 | 806–842 |

| Indium Alloy | 156–200 | 313–392 | 220–240 | 428–464 |

The melting temperature is the minimum temperature at which metal transitions from a solid to a liquid. The optimal pouring temperature is slightly higher to ensure smooth flow and proper filling of mould details. Casting at the right temperature improves flow, minimises defects like air pockets and shrinkage, and protects the mould from overheating. Choose a metal that suits your project, use a thermocouple for accurate monitoring, and preheat and dry the mould to prevent steam-related issues.

This comprehensive Technical Data Sheet is designed to provide all the essential information needed to ensure precision and safety when using ThermaCAST™ Resin.

ThermaCAST™ LIQUID PROPERTIES

SKUs

M/TMC-4141NA

Viscosity

600cps @ 25°C(Brookfield RVT)

Odour

Low

Active Solids

100%

Shelf Life

12 months

UV Cure

385nm to 410nm

Particle Size

< 05um

Cure Speed

3 second Layers (MSLA)

Storage

Dark Cool & Dry Place

Wash Up

RESINAWAY® or IPA

ThermaCAST™ MECHANICAL PROPERTIES

Tensile Strength

45 Mpa

Elongation at Break

1–2%

Direct Heat Resistance

500°C (932°F)

Heat Deflection Temp (HDT)

150°C

Impact Strength

Low to Moderate

Hardness (Shore D)

95–98

Specific Gravity

1.5

Thermal Conductivity

Low

The Safety Data Sheet (SDS) provides detailed and confidential information about the handling, storage, and safe use of ThermaCAST™ Resin. Access to the SDS requires entering your details to ensure compliance with safety standards and protect this proprietary information. This measure helps prevent sharing sensitive data on social media or other public platforms. Click the button below to proceed to the download page and submit your information to receive the SDS securely.

HOW TO ACHIEVE THE HIGHEST DETAILS

ThermaCAST resin is versatile and can be printed between 10 and 100-micron layer heights. To achieve the best results, 3D models should always be designed solid.

Check our printer settings page to see if we have your printer listed, which will give you a good starting point. Use a calibration model to dial in your printer with our resin.

We are here to help! Please get in touch with us if you need assistance. Local manufacturing means local support. You are not just buying a product from a faceless company when you buy from us. We have years of 3D printing and technical support experience. Check out our YouTube Channel and subscribe to keep up with the latest from the resin 3D printing world!

ThermaCAST™ | Final Tips

Keep Moulds Cool Between Casts

Allow your mould to cool completely before reusing to prevent warping or cracking, especially for intricate designs.

Monitor Metal Temperatures

Always use a thermocouple to ensure the molten metal is at the optimal pouring temperature, as furnace gauges can be inaccurate.

Use High-Quality Release Agents

Apply 100% pure talc or fine graphite powder to ensure a clean part release. Avoid cornstarch-based products, as they can burn.

Plan for Safety First

Always work in a well-ventilated area, wear proper PPE (heat-resistant gloves, face shields, and aprons), and keep a powder-based fire extinguisher nearby.

ThermaCAST™ | Recommended Materials & Tools

To ensure optimal results and safety when using ThermaCAST™ Resin for high-temperature metal casting, we recommend the following tools and equipment:

1. Desktop Resin-Based 3D Printer:

Essential for printing your models with ThermaCAST™ Resin.

Shop Resin 3D Printers on Amazon

2. Low-Cost Furnace:

It is necessary for melting metals that require higher temperatures. However, a pot on the stove may suffice for melting low-temperature metals like pewter.

Shop Furnaces on eBay

3. Safety Equipment:

Insulated heat-proof gloves – Find on Amazon

Leather apron – Find on Amazon

Full face shield – Find on Amazon

Safety boots with metal capping – Find on Amazon

Rated mask for fumes – Find on Amazon

4. Ventilation System:

An adjustable extraction duct or fume cupboard is needed to ensure proper ventilation and reduce fume exposure.

Shop Ventilation Systems on Amazon

5. Powder-Based Fire Extinguisher:

Keep close by for safety in case of fire.

Find Fire Extinguishers on Amazon

6. Post-Processing Supplies:

ResinAway or IPA for cleaning printed models

A toothbrush or similar brush for scrubbing uncured material – Shop Brushes on Amazon

Soft cloth or sponge for wiping down models – Find Cleaning Supplies on Amazon

Compressed air or hairdryer to ensure models are free of solvents and moisture – Buy Compressed Air on Amazon

7. Mould Preparation Materials:

Real TALC powder or 30-micron graphite powder for use as a release agent and to protect mould surfaces –

Find TALC Powder on Amazon or

Graphite Powder

Soft makeup brush for applying powder

8. Clamps:

Metal clamps or similar for securing moulds during the casting process –

Shop Metal Clamps on Amazon

9. Basic Casting Tools:

Crucible for melting metal – Find Crucibles on Amazon

Pouring ladle for handling molten metal – Shop Pouring Ladles on Amazon

Tongs for safely handling hot items – Find Tongs on Amazon

11. Optional Priming Equipment:

Lower temperature metal (e.g., pewter) for priming the mould surface –

Shop Pewter Metal on Amazon

12. Cooling Setup:

Optionally, a water bath for purging the mould to cool it before releasing the cast –

Shop Water Bath Containers on Amazon

These tools and equipment will help you achieve the best results with ThermaCAST™ Resin, ensuring safety and efficiency in your high-temperature metal casting projects.

Frequently Asked Questions (FAQs)

ThermaCAST™ is compatible with a variety of low-melting-point metal Alloys (under 550°C), including:

- Pewter

- Zinc and Zinc Alloys (such as ZA2 / 3 / 12)

- White Metals (e.g., Tin Alloys, Bismuth Alloys)

- Bismuth Alloys

- Lead-Free Solder Alloys

- Indium Alloys

NB: Always ensure the materials pouring temperature does not exceed 550°C.

While ThermaCAST™ is durable and suitable for repeated use, high-volume production may require multiple moulds or considering other materials designed for mass manufacturing. ThermaCAST™ is ideal for small to medium-scale projects, prototyping, and bespoke applications.

After post-curing, allow the mould to air dry thoroughly. For added assurance, use a dehydrator or low-temperature oven (40-50°C) for at least 30 minutes, adjusting the time based on mould size. Ensure no moisture or cleaning residue remains by using compressed air or a hairdryer.

Possible reasons include:

- Check the design of the mould: Ensure it has adequate draft angle and is free from any undercuts.

- Insufficient Application of Release Powder: Ensure a light, even layer of talc or graphite powder.

- Overly Tight Clamps: Prevent proper release by adjusting clamp tightness.

- Mould Warping: Excessive heat can warp the mould, affecting release.

- Inadequate Cooling: Allow sufficient cooling time before attempting to remove the part.

Yes, ThermaCAST™ moulds are designed for multiple uses. Proper maintenance, cleaning, and careful handling will extend the lifespan of your moulds. Reapply release powder before each use to ensure easy part release.

If your mould shows signs of warping or cracking:

- Assess Usage: Ensure you are not exceeding the recommended temperature limits.

- Wall Thickness: Verify that mould walls are sufficiently thick.

- Cooling: Allow adequate cooling between pours to prevent thermal stress.

- Storage: Store moulds properly to avoid deformation.

When used according to guidelines and with appropriate PPE, ThermaCAST™ is safe for handling. Always follow safety instructions to minimise exposure to uncured resin and molten metals.

Dispose of excess resin and cleaning solvents in accordance with local regulations. Do not pour resin down drains or dispose of it in regular trash. Refer to your local waste management guidelines for proper disposal methods.

Search on Amazon or eBay for “electric metal melting furnace”. For Safety Gear, check your local hardware store in the welding section for gloves, face shields, and aprons.

Metal Alloys can be found on ebay or Google search, try “casting metals for sale” or visit local metal suppliers for pewter, zinc, or white metal alloys.