FLEX100 Resin (Clearance Item)

Endless bend-abilities with FLEX100 3D Printing Resin

Experience the creativity and versatility of 3D printing with Monocure3D’s FLEX100 resin, this unique resin was designed for creating flexible and bendable models or as an additive to enhance the flexibility of harder materials. Open your imagination and bring your ideas to life with this exceptional resin that excels in producing flexible models.

More Information below.

Description

Endless bend-abilities with FLEX100 Resin

Experience the creativity and versatility of 3D printing with Monocure3D’s FLEX100 resin, this unique resin was designed for creating flexible and bendable models or as an additive to enhance the flexibility of harder materials. Open your imagination and bring your ideas to life with this exceptional resin that excels in producing flexible models.

True Flexibility

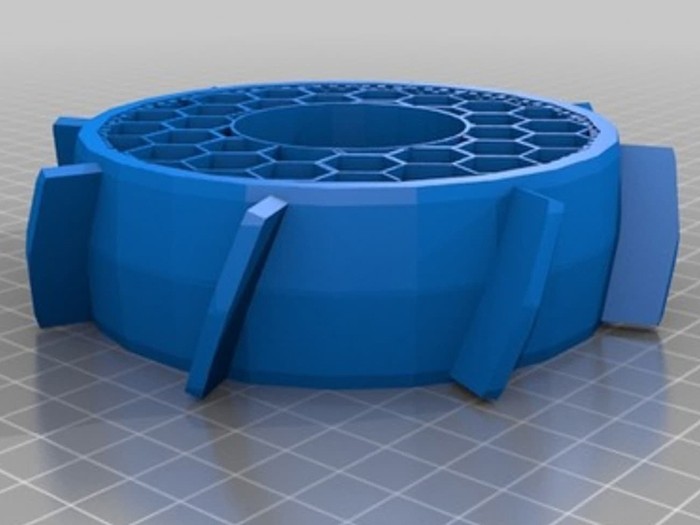

FLEX100 stands out from the crowd with its extraordinary flexibility, enabling you to produce 3D models that can bend, twist, and conform to various shapes without compromising their integrity. This unique property makes FLEX100 the perfect choice for a wide range of applications, including:

-

Flexible prototypes: Create prototypes that mimic the feel and flexibility of real-world objects, allowing you to thoroughly test and refine your designs before committing to production.

-

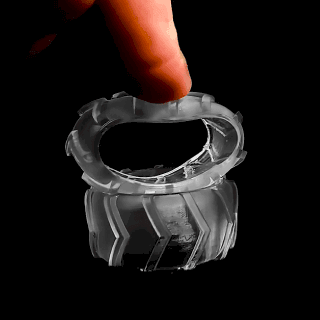

Bendable Models: Design and print parts that require flexibility, such as meshes, gaskets, and shock absorbers. FLEX100 ensures your creations can bend the way you need them to and then spring back to their original position.

-

Wearable accessories Prototypes: Create personalised and comfortable wearable accessories like bracelets, watch straps, and phone cases that flex comfortably with your movements.

-

Artistic creations: Perfect for those with artistic flair to create unique sculptures, figurines, and decorative objects with FLEX100’s remarkable flexibility.

Tailored Flexibility for Every Need

FLEX100 offers exceptional flexibility that can be customised to suit your specific requirements. The thinner the printed part, the more flexible it will be. Additionally, you can adjust the flexibility of your prints by mixing FLEX100 with our other resin systems. Adding a small amount of FLEX100 to our hard resins will enhance their durability and make them less brittle. Conversely, increasing the proportion of FLEX100 will result in a more flexible and pliable print.

Hassle-Free Mixing for Consistent Results

To ensure consistent and repeatable results, we recommend using a scale to weigh the resins when mixing. For a firm and durable resin, try a 25:75 mix, combining 25 grams of FLEX100 with 75 grams of hard resin. For a highly flexible print, aim for a 90:10 mix, using 90 grams of FLEX100 and 10 grams of hard resin.

Optimised Curing for Enhanced Flexibility

When mixing FLEX100 with our other resin systems, it’s crucial to extend the curing time to ensure complete curing of the flexible resin. This slower curing resin requires more UV exposure to fully harden. While the part may appear perfectly formed immediately after printing, insufficient curing can lead to cracks appearing later.

Tuning to Perfection: To achieve optimal results, we recommend visiting our printer settings page. Here, you’ll find comprehensive guidance to finely tune your printer for use with our resin, ensuring you get the best out of every print. If you need further assistance, please contact us through our support page or you can sign up to our Facebook Users Group and get instant help.

Proudly Australian Made & Supported: All our resins are expertly developed and manufactured in Australia, embodying our commitment to high-quality, constancy and trust. Our experienced chemists ensure each product meets rigorous standards. Plus, with our 100% MonoBACK guarantee, you have the confidence to buy, try, and return if not completely satisfied. Experience the Monocure3D difference with every purchase.

Technical Specifications

Resin Type: Soft Urethane Resin

Viscosity: Thin

Curing Wavelength: 405nm UV LED

Post-Cure Time: 30 minutes to 1 hour

Tensile Strength: Moderate

Shore A Hardness: 50

Odour: Moderate

Layer Height: 5-300 microns

Key Features

-

Fast curing time: FLEX100 resin cures in just 3-8 seconds at 405nm UV light, making it one of the fastest curing flexible resins on the market. This means you can print models and parts quickly and easily.

-

High accuracy: FLEX100 is known for its ability to print highly detailed models. This is due to its low viscosity and excellent flow properties, which allow it to capture fine details and produce smooth, even surfaces.

-

True Compatibility: This resin is easy to use and does not require any heat to use. It is compatible with a wide variety of 3D printers and can be printed with a variety of settings.

-

Long Lasting Flexibility: FLEX100 resin does not get harder over time like some of the other flexible resins on the market.

Applications

- Prototypes

- Hobby Models

- Art & Design

- Temporary models

- Educational Purposes

With its exceptional flexibility, ease of use, and versatility, FLEX100 is the ideal resin for both hobbyists and professionals looking to expand their 3D printing horizons. Discover the possibilities and bring your flexible creations to life with FLEX100 today.

Additional information

| Weight | N/A |

|---|---|

| Resin Size | 0.5L, 1L, 5L |

| Resin Colour | Clear |

FLEX60A Resin: Precision Meets Flexibility

Monocure3D is proud to introduce Flex60A Flexible Resin, the perfect solution for applications demanding flexibility, durability, and precision. Available in Black and Translucent, this advanced resin combines exceptional material properties with ease of use, catering to professionals and hobbyists alike.

Flex60A delivers an authentic rubber-like experience featuring exceptional elasticity and rebound. With an elongation capacity exceeding 166%, this resin ensures that your prints maintain their original shape even after being stretched. This unique formulation bridges the gap between robust flexibility and durable performance, setting a new benchmark in flexible 3D printing materials.

Key Advantages of Flex60A Resin

Outstanding Elasticity

Flex60A mimics the properties of rubber, making it ideal for functional prototypes and parts that require flexibility and stretchability.

Durable and Resilient

Engineered for long-lasting performance, the resin maintains integrity under stress and repeated use.

High-Resolution

Achieve detailed prints with minimal shrinkage or splitting, ensuring superior precision for even the most intricate designs.

Versatile Applications

Flex60A mimics the properties of rubber, making it ideal for functional prototypes and parts that require flexibility and stretchability.

4 Printing Tips for Flex60A Flexible Resin

Use Adequate Supports

When working with Flex60A, it’s crucial to provide adequate support to maintain the model’s integrity throughout the printing process. Flexible resins benefit from thicker, well-anchored supports placed strategically in critical areas prone to movement or deformation. Properly positioned supports help prevent sagging or warping during printing. Additionally, ensure the supports are designed for easy removal to avoid damaging the model. Testing and refining your support strategy can make a significant difference in achieving flawless prints.

Increase Lift Height

Adjust the lift height to a higher setting to ensure the resin separates cleanly from the FEP film during printing. This reduces suction forces that can cause print defects, especially with flexible materials like Flex60A. Proper lift height is essential for maintaining the integrity of each layer and preventing warping or tearing during the peeling process. Testing different lift heights can help optimise this step for your printer and resin combination. A well-adjusted lift height minimises stress on the printer’s mechanical components, resulting in more consistently successful prints.

Optimal Post-Cure

Proper post-curing is essential to achieving Flex60A's full potential, ensuring the printed model achieves its intended flexibility, durability, and surface finish. UV post-curing is necessary—place your print in a UV curing chamber for 30-60 minutes. For optimal mechanical properties, heat curing is recommended. This involves a second cure at 60–70°C for 60 to 120 minutes, allowing the material to develop its mechanical strength while maintaining flexibility.

Best Finishing Practices for Flex60A Flexible Resin

1. Careful Removal from the Build Plate: Use a scraper to remove the print from the build plate gently. Take extra care to avoid applying excessive force, as this can deform or damage the model’s edges.

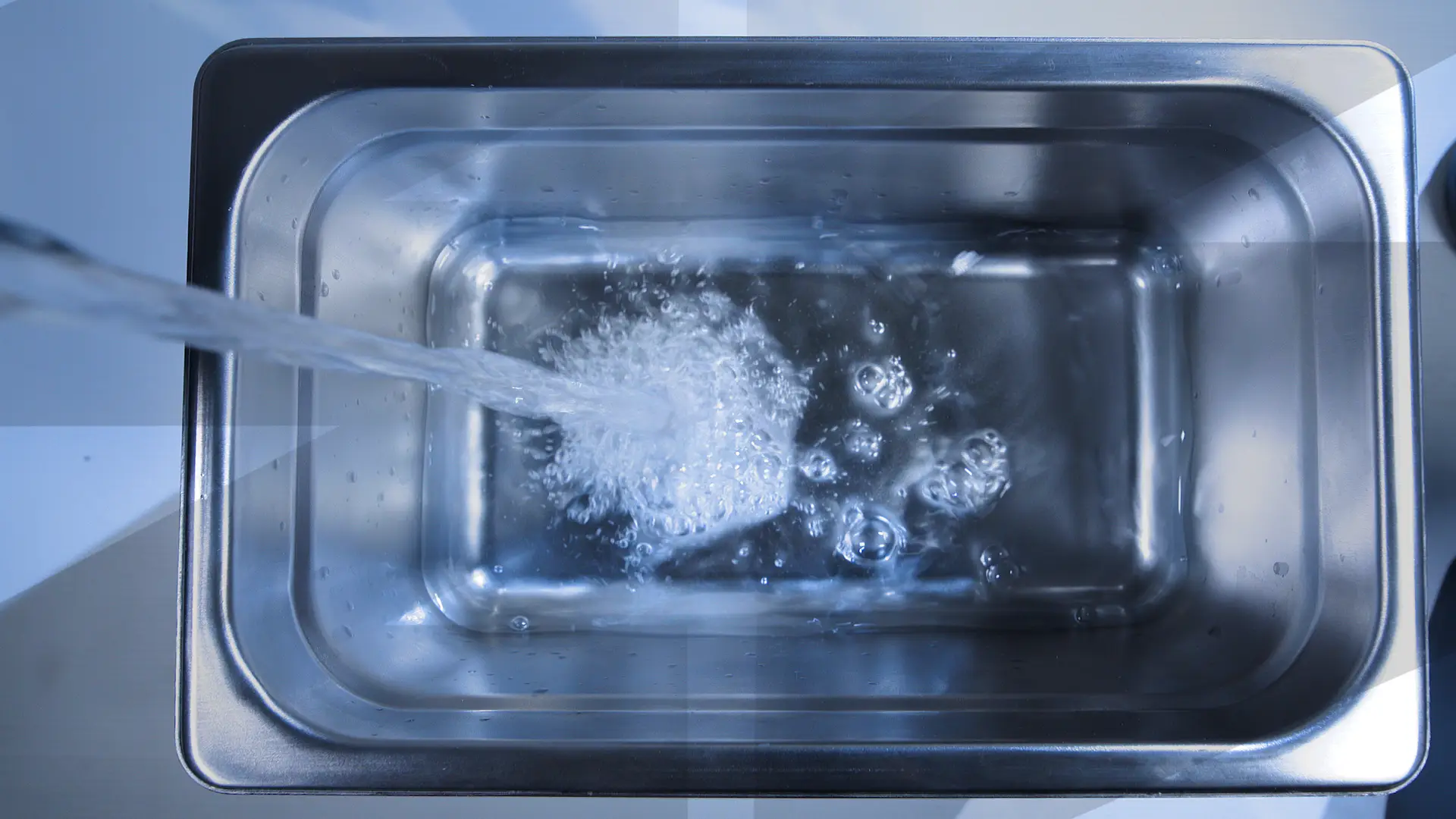

2. Thorough Cleaning: Rinse the printed part in a resin cleaning solution, such as ResinAway, to remove any uncured resin from the surface. Agitate the part gently in the cleaning solution for a few minutes, ensuring all areas are clean and significantly finer details.

3. Dry Completely Before Curing: After cleaning, allow the print to air dry or pat it gently with a lint-free cloth to ensure no cleaning solution remains, as the leftover liquid can interfere with the curing process.

4. Controlled UV Curing: Place the part in a UV curing chamber and follow the recommended curing times and light intensities for Flex60A. Rotate the model periodically during curing to ensure even exposure.

5. Heat Curing: This involves curing at 60–70°C for 60 to 120 minutes, allowing the material to develop its mechanical strength while maintaining flexibility fully.

FLEX60A LIQUID PROPERTIES

Product Code(s)

M/FLX-4161BK, M/FLX-4162T

Colour(s)

Black, Translucent

Viscosity

1400-1800 cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

405nm (optimal)

Cure Speed

2-4secs

Storage

Dark Cool, dry place out of direct sunlight

Wash Up

RESINAWAY® or IPA

FLEX60A MECHANICAL PROPERTIES

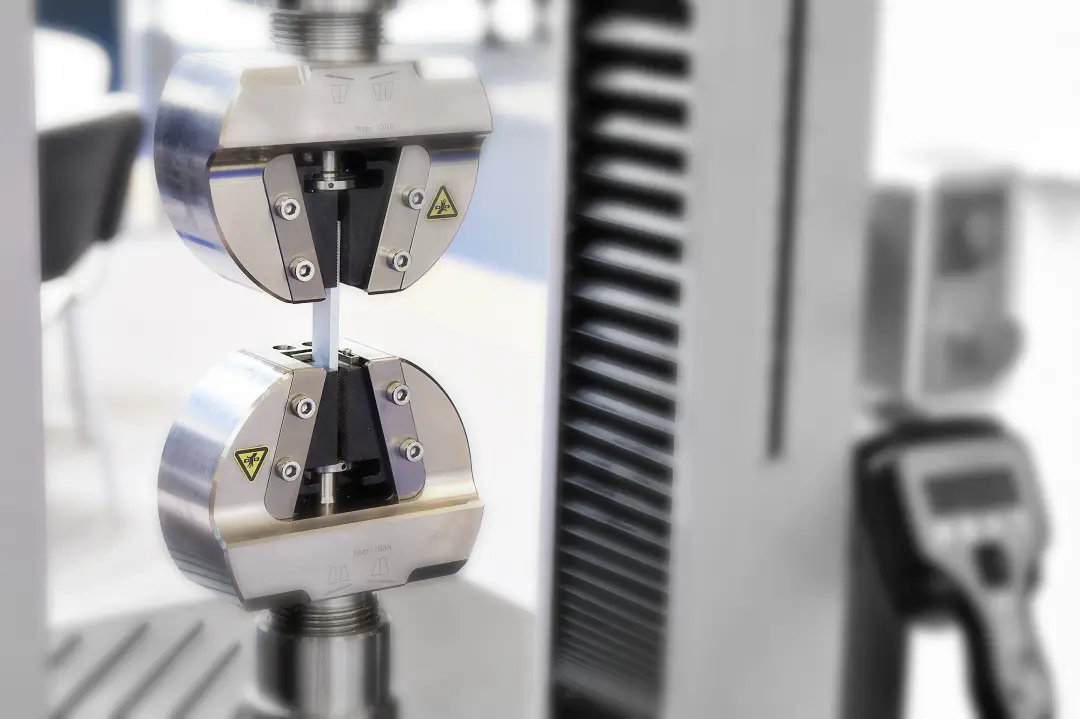

Method Code: ASTM D638-14

Product: Monocure3D FLEX60A Resins (50μm)

Acceptance Code: Supply Findings

Specimen Type: Rectangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

M/FLX-4161BK, M/FLX-4162T

Cross-Sectional Area (mm2)

26.47

Max Force (kN)

1.64

Tensile Strength (MPa)

1.92

Elongation at Break

166.9%

Tensile Modulus

2 Mpa

Flexural Band Span (mm)

89.75

Resilience

15%

Density (g/cm3)

1.00-1.05

Shore Hardness (A)

65-67

Glass Transition Temp

-10°C @ 0.45MPa