MODEL TUFF Resin (Clearance Item)

This product has been discontinued…

We’ve moved this product to our Clearance Store due to the increasing cost and scarcity of a key raw material. Our new range features an improved base that’s easier to print, has low odour, offers better mechanical properties and is more affordable!

Use our Product Finder to explore alternatives by properties, finish, colour, or price. Need assistance? Contact us—we’re here to help!

Description

This Product is Being Discontinued…

We’ve decided to sunset this product as part of our commitment to innovation and meeting our customers’ needs. One of the key raw materials used in this product was becoming increasingly difficult to source and costly, prompting us to create an improved formulation. The new base resin we’ve developed offers easier to dial in, lower odour, superior mechanical properties, and, best of all, a more affordable price!

While we understand that some of you may have relied on this product, we’re confident that our new range will exceed your expectations. To help you find the best replacement, we encourage you to use our Product Finder. You can search by properties, finish, colour, or price, and even type in the name of this product to discover alternatives that match your needs.

If you cannot find what you’re looking for or need assistance, we’re here to help. Contact our office at +61 2 9738 5340 or message us, and our team will guide you in selecting the ideal resin for your projects.

TUFF Resin

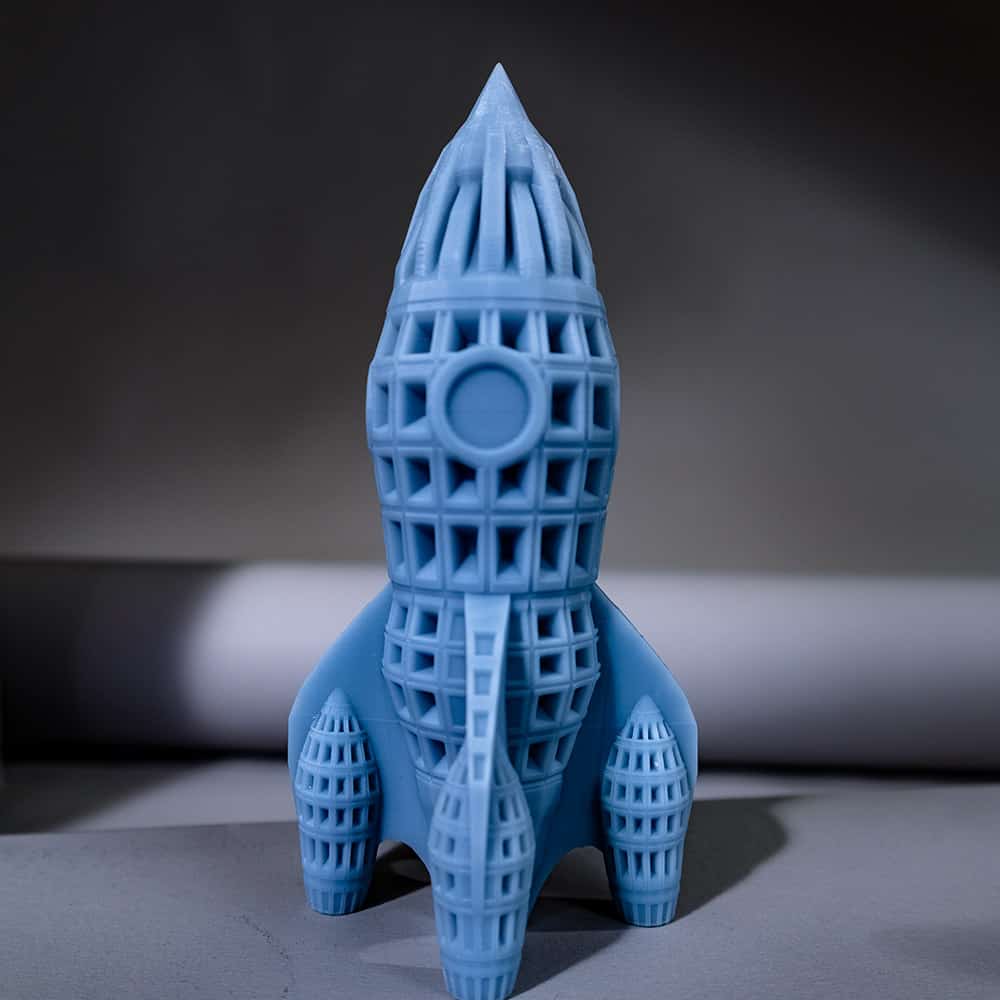

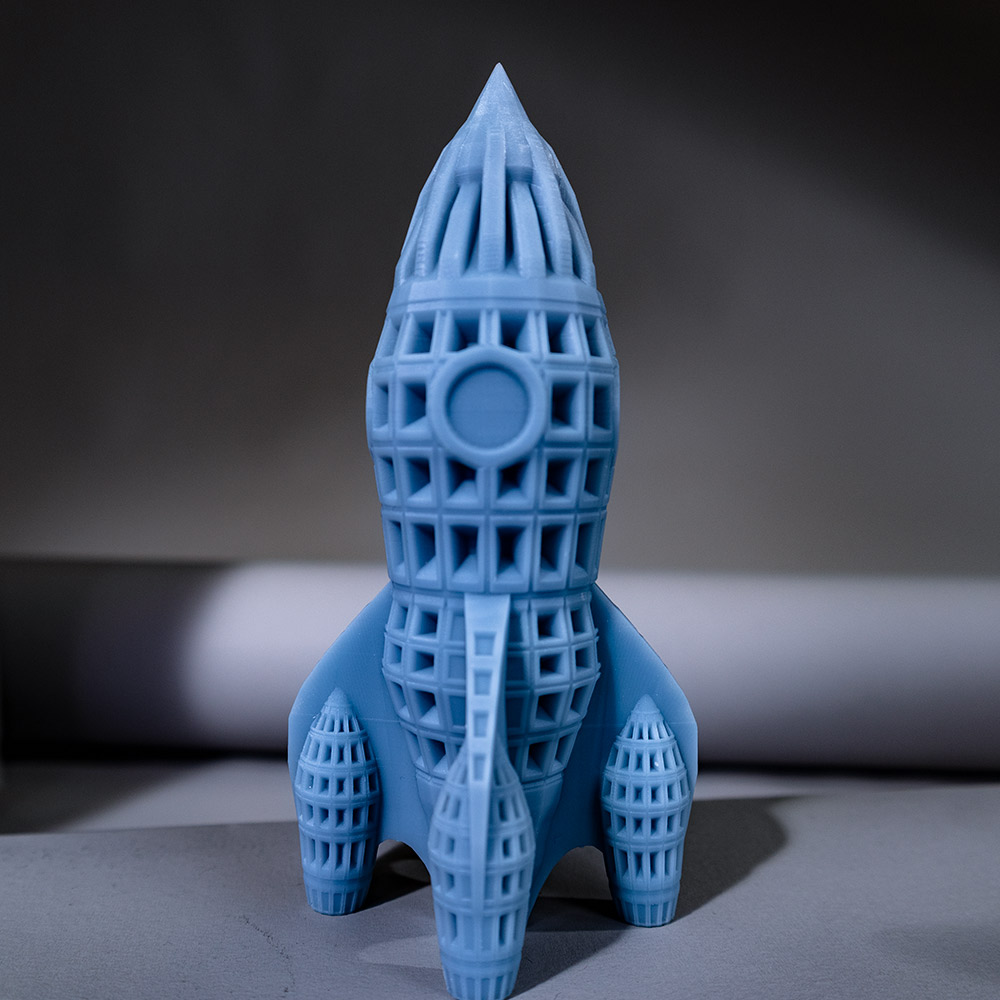

Monocure3D Rapid TUFF Resin, part of our essentials range; you can’t surpass this material for 3D printing robust models that can withstand the toughest demands. This unique blend of advanced urethanes delivers exceptional tensile strength, a hard surface finish, and long-lasting durability. Make this your go-to resin for models that you need to survive the test of time!

Impressive Strength: At the core of Rapid TUFF Resin lies its remarkable strength, far surpassing that of most resins on the market. This means your prototypes can endure high stress and strain without breaking or shattering. Whether you’re making hobby models or testing new product designs, our TUFF Resin will stand up to the challenge.

Durable Hard Surface Finish: With a Shore D hardness rating of 92, Rapid TUFF Resin boasts a hard surface finish that is both durable and aesthetically pleasing. This smooth finish is perfect for painting or other post-processing techniques, allowing you to create prototypes that function flawlessly and look exceptional.

Longevity Built to Last: Rapid TUFF Resin is designed to withstand the test of time. Extensive aging tests have proven its exceptional durability, ensuring your prototypes retain their integrity for years to come. Rapid TUFF Resin is the ideal choice for long-term testing, research, and development projects.

Proudly Australian Made & Supported: All our resins are expertly developed and manufactured in Australia, embodying our commitment to high-quality, constancy and trust. Our experienced chemists ensure each product meets rigorous standards. Plus, with our MonoBACK guarantee, you have the confidence to buy, try, and return if not completely satisfied. Experience the Monocure3D difference with every purchase.

Tuning to Perfection: We recommend visiting our printer settings page to achieve optimal results. Here, you’ll find comprehensive guidance to finely tune your printer for use with our resin, ensuring you get the best out of every print. If you need further assistance, please contact us through our support page, or join our Facebook Users Group for instant help from our other members!

Technical Specifications

- Resin Type: Durable Urethane Resin

- Viscosity: Low

- Curing Wavelength: 405nm UV LED

- Post-Cure Time: 30 minutes to 2 hours

- Tensile Strength: High

- Shore D Hardness: 92

- Odour: Low

- Layer Height: 5-300 microns

Additional information

| Weight | N/A |

|---|---|

| Resin Size | 0.5L, 1L, 5L |

| Resin Colour | Army Green, Clear, Grey, White |

Prototypes | Miniatures | Tooling | Hobby | Housings | Durable Parts | Connectors | Jigs | Outdoor Parts

WHY CHOOSE TUFF™ RESIN?

High Tensile Strength

When measuring the Tensile strength of our material, the pressure is applied to it gradually until it gives. TUFF™ resin has a much higher rating than most resins on the market.

Hard Surface Finish

A hard surface rating of Shore D 92, without being brittle, gives TUFF™ its unique properties. When post-cured, the smooth surface finish is perfect for painting if required.

Longevity & Durability

It’s important that your model lasts the test of time, we have done comprehensive aging tests and TUFF™ has passed with flying colours.

The Offical Test Figures

We had an independent lab do this report on our TUFF™ resin, printed at different heights and with varying cure times. You can download the test report here.

WHAT MAKES TUFF™ RESIN SO UNIQUE?

Monocure 3D TUFF™ resin is a unique blend of advanced urethanes. It was specifically developed to produce a 3D printed model with high tensile strength and long-life durability. These properties provide the right balance of fine detail, strength, flexibility and a hard surface finish.

We recommend using TUFF™ resin if you intend to 3D print models that you want to remain rigid and hard yet withstand stress and strain without being brittle. Once post-cured, it can be machined, painted or polished for further finishing.

Our development team has created TUFF™ resin to be low in viscosity (thinner), so it doesn’t require heating like other resins on the market. Thinner materials can reduce the build-up of resin that can get trapped behind supports.

TUFF™ has a low odour formula to suit confined spaces such as home offices, garages and family living spaces.

TUFF™ MECHANICAL PROPERTIES

Method Code: ASTM D638-14

Product: Monocure 3D TUFF™ Resin (25μm)

Acceptance Code: Supply Findings

Specimen Type: Retangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

3DT-3873C, 3DT-3873GY, 3DT-3873W, 3DT-3960G

Cross-Sectional Area (mm2)

26.47

Max Force (kN)

1.64

Tensile Strength (MPa)

62

Elongation at Break

4

Young’s Modulus (GPa)

0.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

348

Shore Hardness (D)

92

Heat Deflection Temp

71°C @ 0.45MPa

TUFF™ PRINTING TIPS

Ensure a long post-cure to increase the tensile strength.

Printing at a lower layer height will increase the overall strength.

Print the part solid, not hollow for the strongest results.

Always print models on a 45 degree angle to help the part release from the FEP sheet.

TUFF™ resin is versatile and can be printed between 5 & 100-micron layer heights. To achieve the best results, 3D models should always be designed solid, if hollowing is required, ensure drain holes are included to remove any trapped resin.

Always print large flat areas on an angle to help with print deformation due to the adhesion to the FEP film. To assist with unsupported areas, ensure you use well-positioned, solid supports.

We recommend you add a 1-2 seconds wait after print setting to allow the material to cool after curing before starting to lift the build plate. (Not all slicers have this setting, check with your software provider) This resin will print faster than our rapid model resin, please adjust your settings accordingly. Use a calibration model to dial in your printer with our resin. Check our printer setting page to see if we have your printer listed to give you a good starting point. Make sure you subscribe to our ProTips Channel to keep up with the latest from the M3D team.

TUFF™ PHYSICAL PROPERTIES

Product Code(s)

3DT-3873C, 3DT-3873GY, 3DT-3873W, 3DT-3960G

Viscosity

200 cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristic

Active Solids

100%

Shelf Life

36 months

UV Cure

225nm to 420nm

Particle Size

< 10μm

Cure Speed

1.5 – 2 seconds (mono)

Storage

Dark cool, dry place

Wash Up

RESINAWAY® or IPA

TUFF™ FINISHING TIPS

- For best results after printing, use ResinAway® for removing uncured resin from the part. Place part in a pre-wash bath filled with ResinAway® and use a soft brush to remove excess resin. Follow by placing the component into an ultrasonic cleaner with ResinAway® for 3-5mins to help remove the resin trapped in the finer detail.

- Ensure parts are dry by using compressed air or patting gently with a lint-free cloth before post-curing – Warning: leaving excess IPA or ResinAway® on parts might result in surface cracking.

- TUFF™ requires post-curing to reach its optimal mechanical properties. We recommend using a 405nm LED Ultraviolet light to post-cure the model. It is recommended to post-cure for a few minutes, then remove the excess ResinAway by washing with fresh water. Then place it back in the curing chamber for at least 30 mins to improve the tensile strength of the resin. (2 hours will further enhance the mechanical properties. These properties will also increase over a few days).

- When exposing a part to external elements, apply paint to the surface to improve longevity. Alternatively, the components can be machined, sanded and polished to create a tough scratch resistant surface.