CustomMix™ Additive | Flex

Flex Additive Concentrate for Tensile Resin

Our Flex Additive Concentrate is specifically formulated to be mixed with Monocure3D’s Hard Resin systems, providing enhanced flexibility and impact resistance to your 3D-printed parts. This additive ensures that your models are durable and less prone to breakage. It makes them perfect for applications where flexibility is essential without compromising printing quality or material properties.

Description

Flex Additive Concentrate

Featuring ‘CustomMix’ technology by Monocure3D

Use the ResinBOT formula Calculator

Additional information

| Weight | 0.5 kg |

|---|

CustomMix™ - 3D Printing Resin your way!

CustomMix is the world’s first system designed to customise 3D printing resins with concentrated additives, offering you versatility and customisation. This innovative solution enables you to adjust your resin’s properties to suit any project perfectly. Whether you need a matte finish, a particular colour, semi-translucency, enhanced flexibility, or impact resistance, CustomMix allows you to create a resin tailored to your requirements.

What sets CustomMix apart from traditional methods, such as adding CMYK pigments, is its inclusion of Monocure3D’s latest urethane base resin, photoinitiators and special additives. The key components used in all our high-performance resins. This ensures that when you add CustomMix additives, you’re not altering the essential properties of the original resin and compatibility with printer settings, giving you consistent results every time without the need for recalibration.

With CustomMix, you can create resins that meet your needs without compromising quality or ease of use. Look for the CustomMix Compatibility Symbol and start formulating resins to meet your specifications.

Why Choose CustomMix™

Highly Versatile System

Customise your resin with a variety of additives for any specific requirement.

Cost-Effective Solution

Only pay for the additives you need, keeping the resin affordable.

Quality Assurance

Adding concentrates will not compromise the essential properties of the resin

Easy Customisation

Our exclusive ResinBot™ can help you create unique formulas for the perfect resin.

How CustomMix Works

With CustomMix™, you can mix and match concentrates to fine-tune your resin’s performance and aesthetic qualities. Follow our tested formulas or create your own to achieve the desired results. Look for the CustomMix Compatibility Symbol on resins to ensure they are designed for seamless integration, maintaining optimal performance and core properties.

Matte Finish

Provides a smooth, matte finish to your 3D printed models, ensuring a professional appearance and primer-free painting.

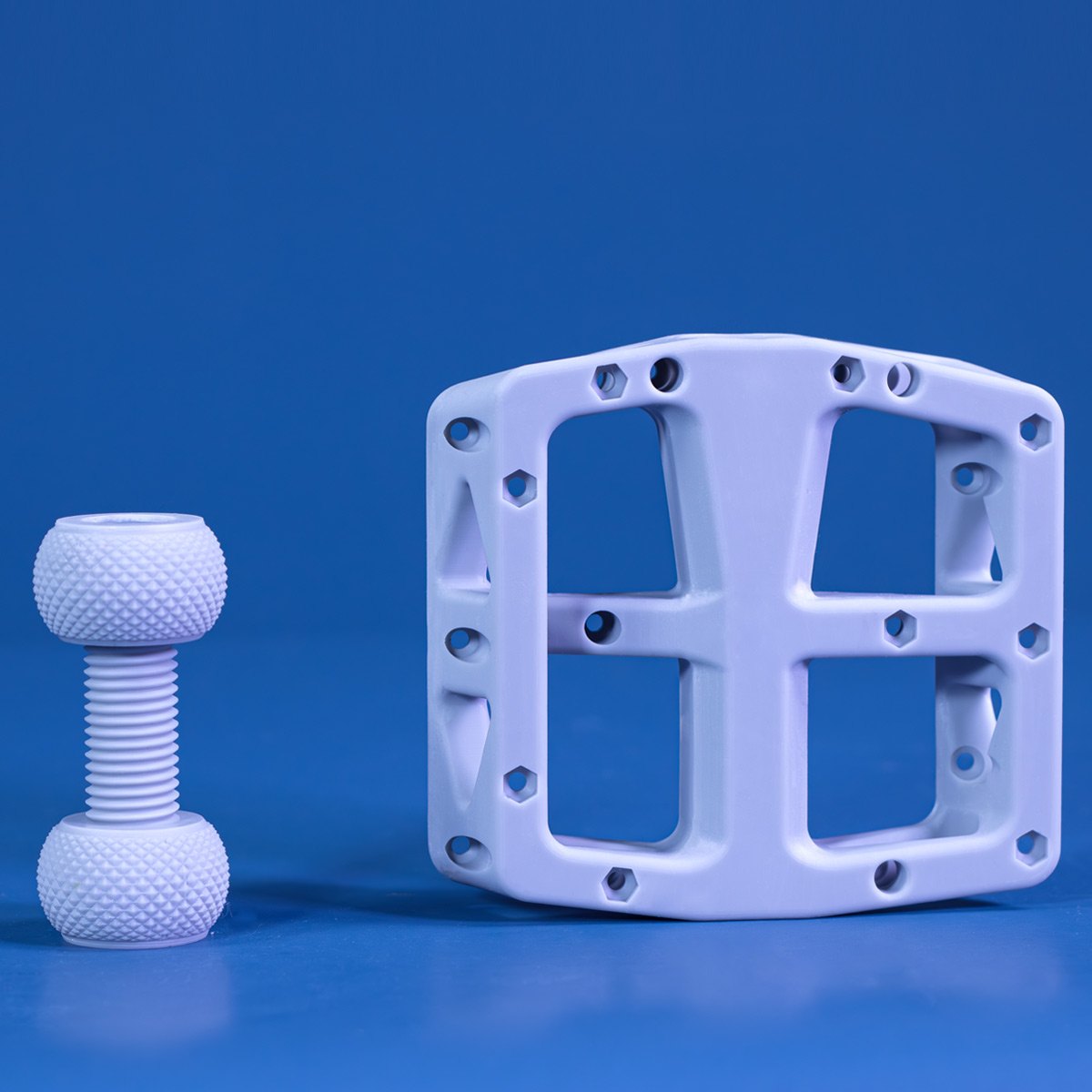

Impact Resistance

Designed to enhance the flexibility, durability and impact resistance of your 3D printed parts with precision and ease.

Colour Toners

Add vibrant, consistent colour to your 3D prints with ease while maintaining the resin’s original properties and performance.

Special Effects

Unique enhancements, including pearlescent and colour-shifting options, bring your 3D Models to life with captivating visual effects. (Coming Soon)

CustomMix ResinBot

Base Resin: 0 grams (0%)

Matting Additive: 0 grams (0%)

Flex Additive: 0 grams (0%)

White Toner: 0 grams (0%)

Cyan Toner: 0 grams (0%)

Magenta Toner: 0 grams (0%)

Yellow Toner: 0 grams (0%)

Black Toner: 0 grams (0%)

Guidelines for CustomMix

1. Shake Well

CustomMix™ additives are concentrated and must be shaken well before use to ensure uniform distribution.

2. Use Scales

Always use scales to measure CustomMix™ additives by weight, not volume, for precise and repeatable formulas.

3. Test First

Always start with a small test mix in a clear cup to ensure the desired results. Once satisfied, scale up the formula for larger batches confidently.

4. Record Formula

Record your CustomMix™ additive amounts and resin combinations to ensure repeatable results for future projects.