We are here to help. Our customers get true-blue support!

The FAQ section provides answers to frequently asked questions, offering valuable insights and solutions to common queries about our products, services, and more.

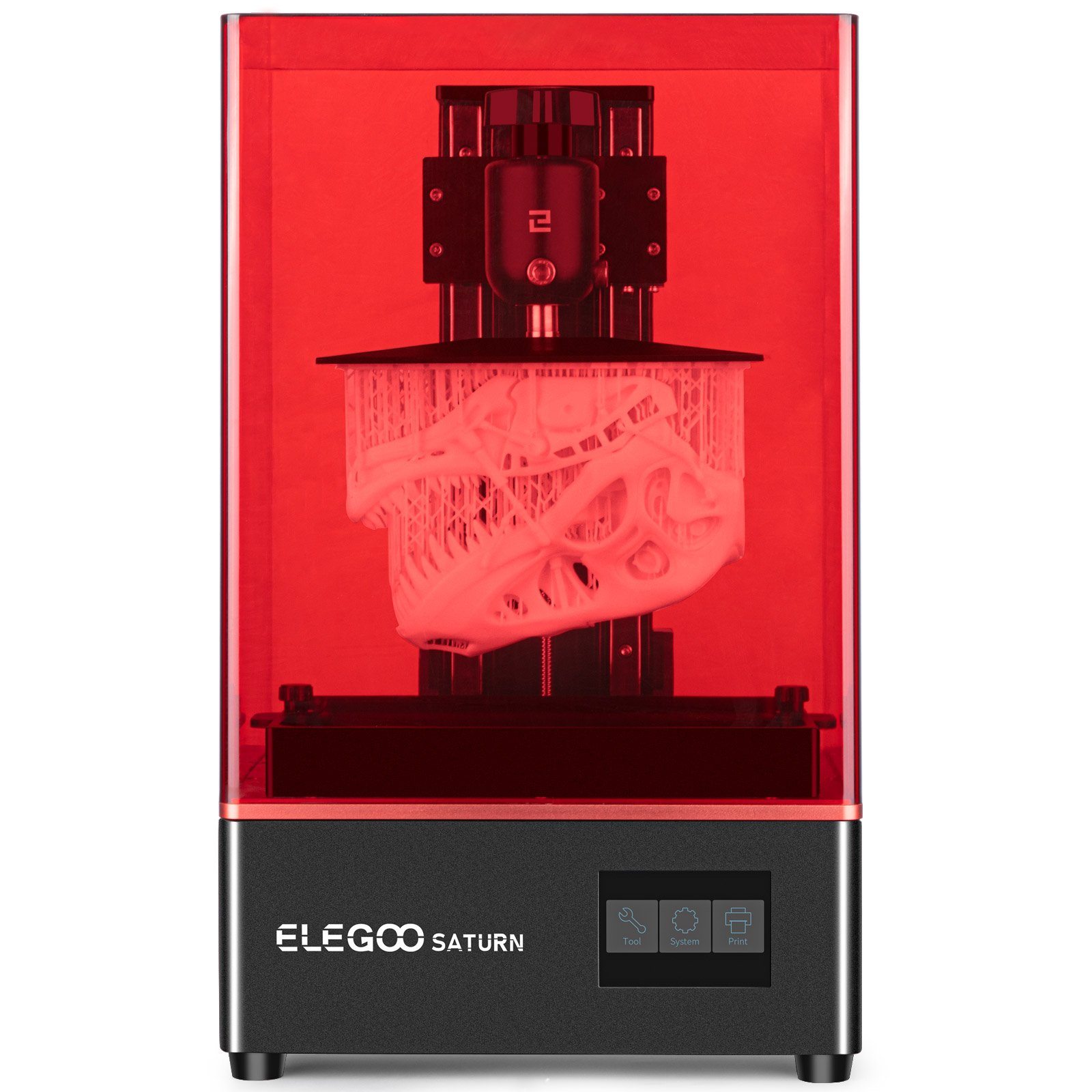

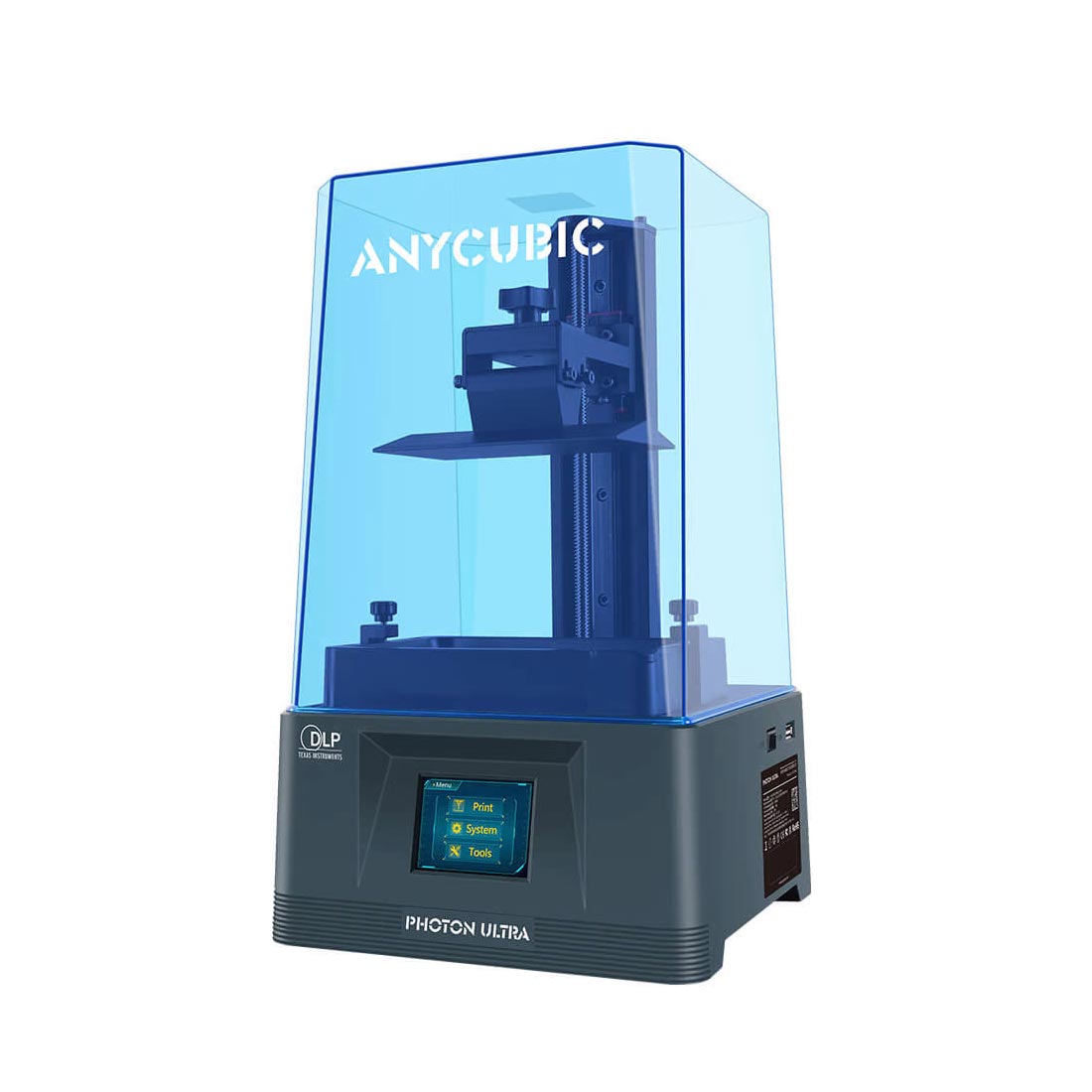

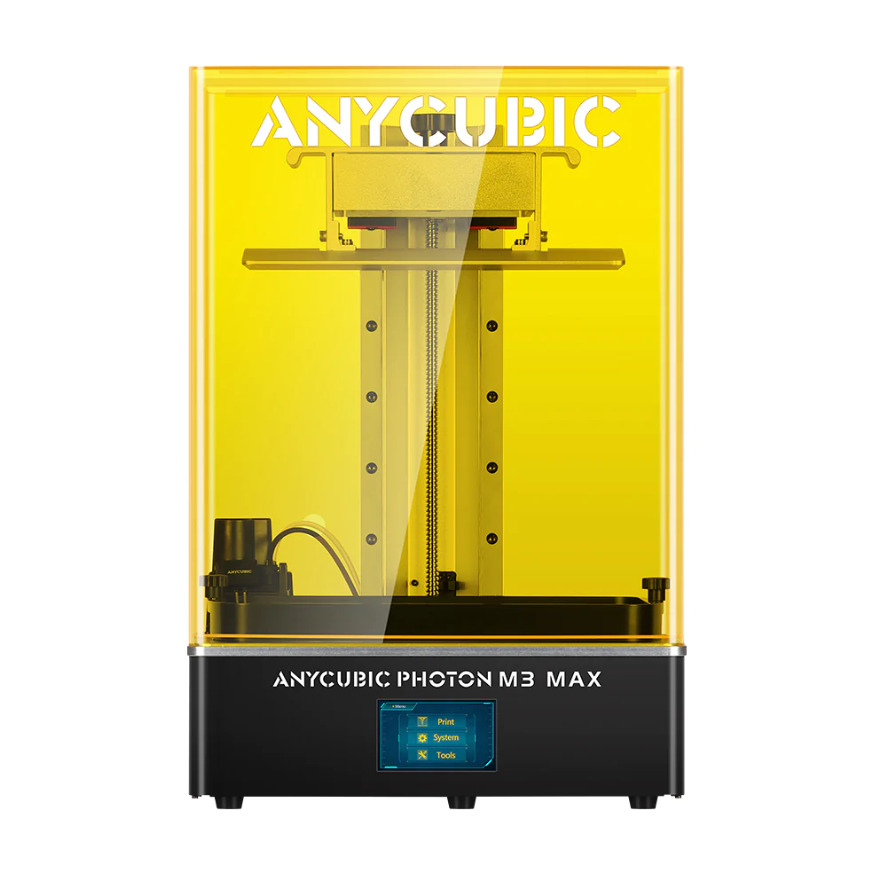

For help dialling in our resin with your printer, find your printer on our settings page. We have also included printer specifications, information, reviews & videos.

Welcome to Monocure 3D Protips! Your dedicated 3D Resin printing channel and set! We're here to educate you on all things 3D printing.

Need to contact us? You can call M3D HQ on +61 (0) 2 9738 5340. Alternatively, please send us a message below, and we will reply.

Contact Us