What are the Differences Between MSLA DLP and SLA 3D Printing?

3D printing technology has evolved significantly, creating multiple methods for creating precise, high-resolution objects. Among these, MSLA, DLP, and SLA 3D printing technologies are commonly used for resin-based printing. While these methods share similarities in principle, they each utilise distinct processes and hardware to achieve their results. Understanding these differences is essential for choosing the right technology for your needs.

SLA 3D Printing: Precision Through Lasers

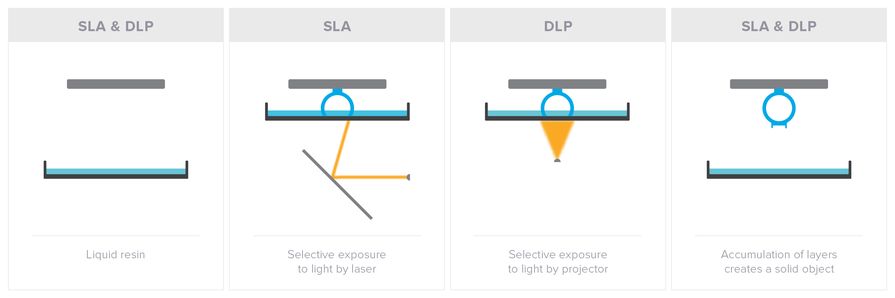

SLA (Stereolithography) 3D printing is one of the earliest forms of resin printing. This technology uses a laser to cure liquid resin layer by layer, creating a solid object. The laser beam is directed across the print area using two precision motors, called galvanometers, positioned on the X and Y axes. These galvos control a pair of mirrors that rapidly angle to guide the laser beam to specific points.

The laser cures the resin by tracing the model’s layers as a series of points and lines, resulting in highly detailed prints. Due to this point-by-point curing method, SLA printers are renowned for their accuracy and smooth surface finish, making them ideal for applications requiring intricate details, such as jewellery, dental models, and prototypes. However, this precision often comes at the cost of slower print speeds compared to other methods.

DLP 3D Printing: Speed Through Projection

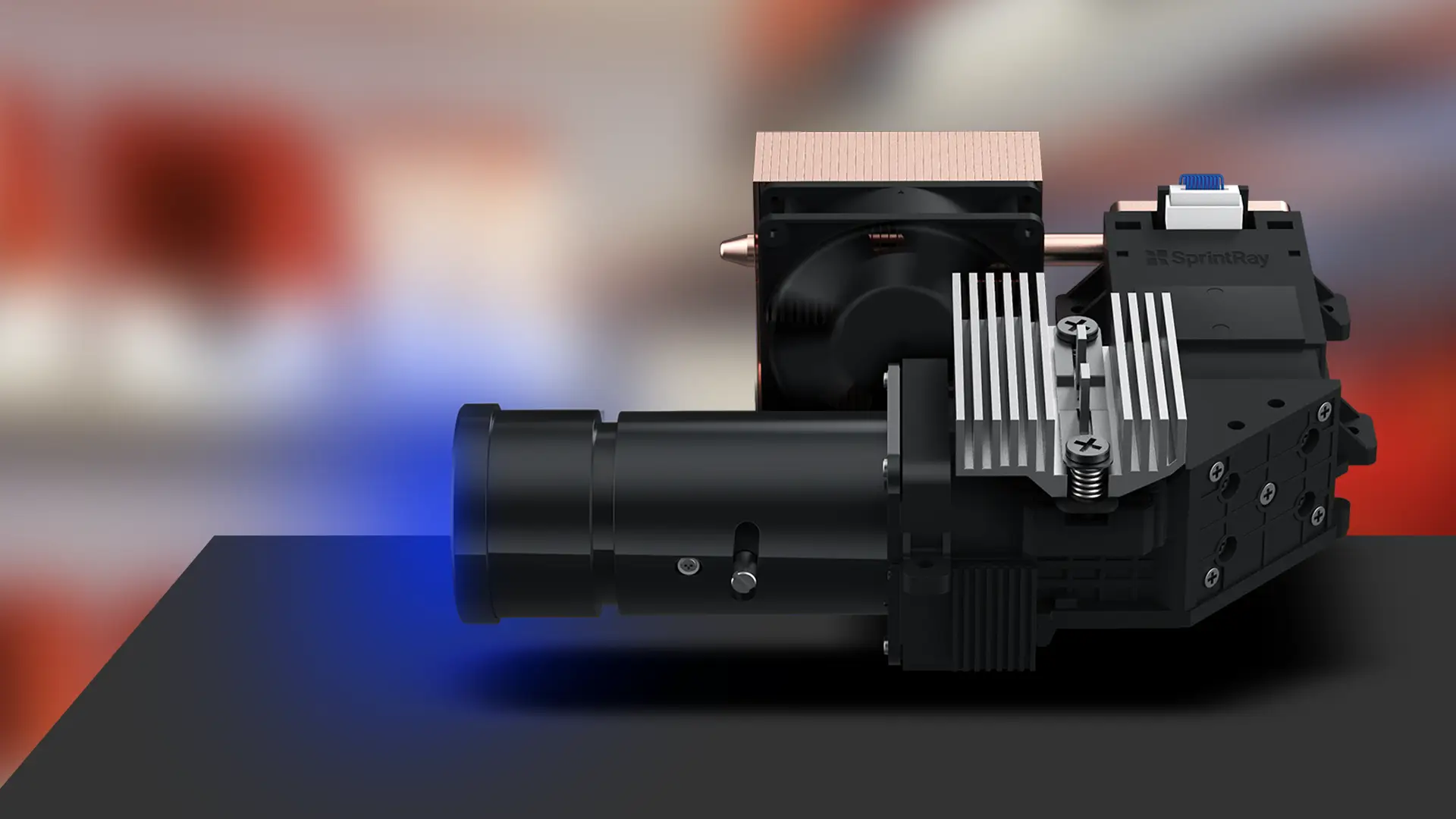

DLP (Digital Light Processing) 3D printing operates on a similar principle to SLA but uses a different light source to cure the resin. Instead of tracing the model with a laser, DLP printers project an entire image of each layer onto the resin surface simultaneously using a digital projector screen.

This process relies on a grid of square pixels, so each layer is represented as a series of tiny squares called voxels. Because DLP technology cures an entire layer at once, it is generally faster than SLA, particularly for large prints. However, the pixel-based approach may result in slightly less smooth surfaces compared to SLA, depending on the resolution of the projector.

DLP printers are an excellent choice for those prioritising speed without sacrificing too much detail, making them popular for industrial applications and rapid prototyping.

LCD 3D Printing: Affordable Precision

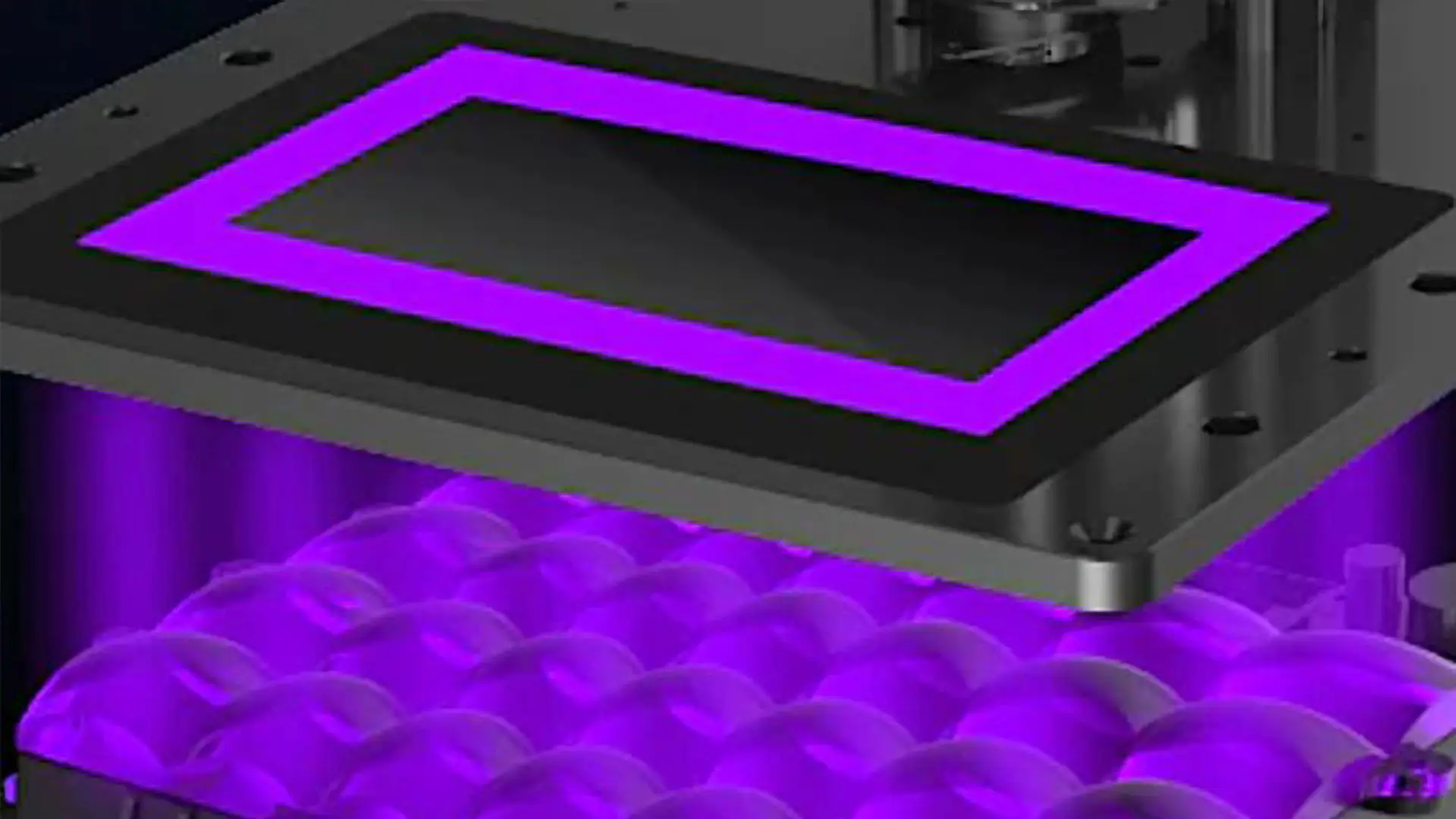

MSLA or LCD (Liquid Crystal Display) 3D printing shares many similarities with DLP. Both technologies project light to cure resin one layer at a time. However, instead of a digital projector with micro-mirrors, LCD printers use a bank of UV LEDs that shine light through a liquid crystal display (LCD) panel. The LCD panel acts as a mask, selectively blocking or allowing light to pass through to cure the resin layer.

Because LCD printers rely on the resolution of the LCD screen, they can often achieve high detail at a lower cost than DLP. However, the LED bank and LCD panel are subject to wear and may require replacement after extended use.

A growing number of manufacturers are branding LCD-based resin printing under new terms. For example, Structo and Prusa have referred to it as Mask SLA (MSLA), emphasising its use of a masking layer for precise curing. The Prusa SL1 is an example of an MSLA printer designed to combine accuracy and affordability.

Key Differences

- Light Source:

- SLA uses a laser beam guided by mirrors.

- DLP uses a digital projector to flash the entire layer at once.

- MSLA uses a UV LED array with an LCD screen as a mask.

- Layer Curing Process:

- SLA cures resin point by point.

- DLP and MSLA cure entire layers at once.

- Resolution and Detail:

- SLA offers exceptional detail due to its laser precision.

- DLP’s detail depends on the projector’s resolution.

- MSLA detail depends on the resolution of the LCD screen.

- Print Speed:

- SLA is slower due to its point-by-point curing process.

- DLP and MSLA are faster as they cure entire layers simultaneously.

- Cost:

- SLA printers are often the most expensive due to their laser systems.

- DLP printers are moderately priced but still higher than LCD printers.

- MSLA printers are typically the most affordable of the three technologies.

Choosing the Right Technology

Selecting the best 3D printing technology depends on your application, budget, and performance requirements. SLA is ideal for projects requiring the highest precision and smooth finishes. DLP balances speed and detail, making it a versatile option for many use cases. LCD offers an affordable alternative while still delivering excellent results, particularly for hobbyists or small-scale production.

No matter which technology you choose, understanding these differences can help you make an informed decision and achieve the best results for your 3D printing projects.