The Future of Resin 3D Printing Starts Here!

Introducing AutoFILL™

Filling is just the beginning…

AutoFILL™ | For Everyone and Every Printer

Designed, Developed and Manufactured by Monocure3D Australia

Resin 3D printing is revolutionising the way parts are manufactured, from prototypes to production. The materials developed by Monocure3D have advanced rapidly in recent years, now offering mechanical properties comparable to ABS plastic and Nylon, while new flexible formulations are pushing this technology to the next level. However, anyone who prints with resin is familiar with the struggles of small vats, forgotten top-ups, mid-print failures, wasting time and money.

AutoFILL™ solves all that. It automatically refills your vat, prevents dry runs, and keeps your prints running safely and smoothly, so you can focus on creating, not topping up.

A World First in Resin Handling Technology

- Automatic Resin Replenishment – Maintains optimal vat levels without manual intervention.

- Compatible with all resin-based Printers – Simple tubing setup for universal use.

- Smart Sensor Technology – Detects resin levels in real-time to prevent overfilling.

- Low-Noise Operation – Quiet performance for studio, lab, or home environments.

- Compact & Durable Design – Built to fit seamlessly into your existing setup.

- No-Touch screen Interface – Easy-to-use controls with adjustable settings.

- Safe & Reliable – Designed by experienced 3D printing professionals with safety in mind.

A World First in Resin Handling Technology

- Automatic Resin Replenishment – Maintains optimal vat levels without manual intervention.

- Compatible with all resin-based Printers – Simple tubing setup for universal use.

- Smart Sensor Technology – Detects resin levels in real-time to prevent overfilling.

- Low-Noise Operation – Quiet performance for studio, lab, or home environments.

- Compact & Durable Design – Built to fit seamlessly into your existing setup.

- No-Touch screen Interface – Easy-to-use controls with adjustable settings.

- Safe & Reliable – Designed by experienced 3D printing professionals with safety in mind.

The Smart Way to Print

Fully automated resin top-ups

AutoFILL™ monitors your vat and adds resin when needed, eliminating the need for manual refills.

Enjoy uninterrupted printing, even on long or high-volume jobs.

Prevents mid-print failures

Never lose a print due to an empty vat again.

AutoFILL ensures consistent resin flow from start to finish.

Works with any MSLA/DLP printer

Designed for universal compatibility across most resin printers.

No special adapters or proprietary systems required.

Whisper-Quiet Operation

The precision peristaltic pump runs silently in the background.

Easily swap hoses when a colour change is required.

Smart Overflow Prevention

Peace of mind, built in.

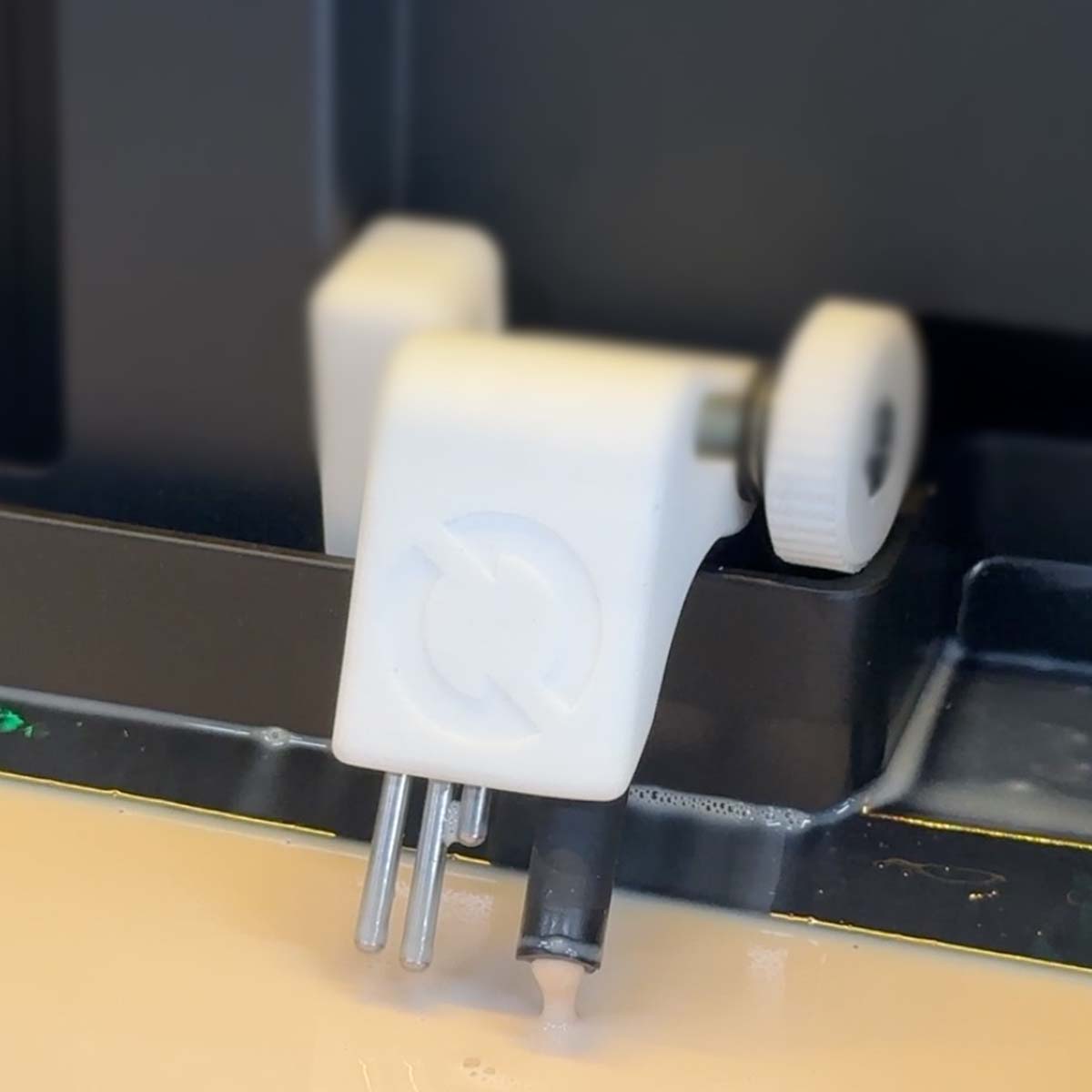

Triple-Level Sensing

Three independent sensor pins precisely monitor resin levels.

-

The two primary sensor pins ensure the optimal fill height is maintained.

-

A third emergency sensor pin acts as a safety backup, reversing the pump if levels rise too high.

Time-Based Cutoff

The system tracks fill duration and stops the pump if it exceeds the safe time limit, providing an added safeguard in case sensors ever lose contact or resin flow is restricted.

Intelligent Pump Logic

Once the primary sensor detects a full vat, the pump stops instantly. It won’t restart until manually reset — ensuring safe, deliberate operation and preventing unwanted overfill due to sensor error.

Regular Sensor Checks

Before every fill cycle, the system performs a diagnostic scan of all sensors. If any sensor fails the check, AutoFILL won’t initiate the process, keeping your printer safe.

Software Safeguards

Smart software constantly checks for logical inconsistencies — like a sensor triggering while the pump is off — to detect faults before they become problems.

Set and Forget with 20kg Resin Support

We wanted a system that could feed resin continuously from 20kg UV-safe containers, keeping the workflow clean and uninterrupted. But we also knew no one was shaking a 20kg resin cube.

We built a simple, open-source mixing system using 3D-printed parts and a small gear motor. It automatically mixes the resin a few times a day, or can be set to manual mode for a more aggressive stir. This is ideal if the resin has been sitting for a while. The resin is drawn from the bottom of the drum via a custom-designed 3D-printed intake, which ensures a consistent flow of well-mixed material.

Intuitive Rotary Menu

Powerful control made simple.

AutoFILL™ is built with an easy-to-navigate rotary interface, so you’re always in control. No sticky fingers on a touch-screen!

RUN MENU

Quick-access to core operations:

- Auto FILL – Maintain optimal vat levels automatically

- Manual – Manually control resin flow

- Auto Cycle – Alternate filling/pausing in cycles

- Auto Empty – Drain your vat with a single tap

SETTINGS MENU

Customise your user experience:

- Mute / Volume Control (1 - 10) – Adjust or silence system sounds

- Brightness (1 – 10) – Set screen intensity to match your environment

- Empty Alarm ON/OFF – Enable alerts for low resin levels

INFORMATION MENU

Helpful system tools and power options:

- Statistics – View important details or diagnostic info

- Help – QR code for instant access to Support.

- System Self Test - Runs through a diagnostic test.

- Power OFF – Hold 5 seconds to shut down the unit safely

Built by Resin. Made for Resin.

AutoFILL™ has been engineered with resin 3D printing in mind. The main body, sensor arm, and foot are all 3D printed using our high-performance resin. Designed specifically for resin printers, the components print cleanly with no supports required. Strategic blade supports are used in open areas, such as the LCD screen cutout, and can be easily removed before post-curing.

- Kit Only (unbuilt) – Includes all electronics, pump, hardware and AutoFILL™ Resin (you print the parts)

- Finished Product – Fully built AutoFILL™, includes pre-printed parts using our specially formulated AutoFILL™ resin

A bottle of this custom-labelled resin will also be available for those who want to print the parts themselves with guaranteed compatibility and performance.

FAQ (Frequently Asked Questions)

Q: What is the AutoFILL™ system?

A: AutoFILL™ is an innovative resin pump system that automatically maintains optimal resin levels in your 3D printer vat. Developed by resin printing experts, it works with virtually any 3D printer and includes advanced safety and mixing features.

A. Yes. AutoFILL is designed as a universal system compatible with most open resin MSLA and DLP printers. It installs externally and integrates with existing vats. Some printer models may require minor adjustments to allow routing of the sensor cable and resin feed tube.

A: It uses a dual-level sensor system. One sensor maintains the correct fill level, while a secondary sensor acts as an emergency shutoff if levels rise unexpectedly. Software checks and timed cutoffs provide additional layers of safety.

A: AutoFILL™ features:

- AutoFill Mode: Automatically fills the vat as needed.

- Auto Empty Mode: Automatically empties the vat as needed.

- Manual Mode: Manual control for on-demand filling.

- Cycle Mode: Repeated filling at set intervals.

A: It includes an intuitive rotary switch for clean, resin-free control—no touchscreen required. The interface also features a bright, adjustable display and easy menu navigation.

A: Yes. The system includes 3D-printable parts to help reduce cost and allow easy replacement. STL files will be provided after purchase.

A: AutoFILL™ is compatible with any size bottle or container. We will also offer a 20kg UV-safe cube option with an integrated automatic mixing system to keep resin uniform and ready for consistent printing.

A: Use the Manual Mix Mode to activate a stronger mixing cycle for older or settled resins before printing.

A: AutoFILL™ was designed by the team at Monocure3D—resin printing experts with over a decade of hands-on experience in developing, testing, and using 3D printing resins.

A: We’re finalising testing with early adopters. Sign up to be notified when it’s ready for release! Please register to receive updates and be the first to access early-bird specials on Kickstarter.

A. AutoFILL will be offered in two versions at launch.

The first is a kit version for users who are comfortable assembling the unit and printing the required parts themselves. This option will include all electronic components and hardware, along with a bottle of our latest Tensile+ resin for printing the structural parts.

The second option is a fully assembled version, supplied complete and ready to install with all printed components included.

Final pricing will be confirmed at launch, with early supporter pricing available through Kickstarter.