Perfecting Your Castings with Free 3D Models

Achieve flawless metal castings with our collection of Free 3D Models for metal Casting, explicitly designed for use with ThermaCAST Direct Metal Casting Resin. Whether you’re fine-tuning your casting setup or testing metal flow and detail accuracy, these calibration and mould designs will help you get the best results.

Each file is optimised to assess fine detail reproduction, metal flow, and casting consistency, ensuring your prints translate into high-quality metal parts. Download, print, and cast with confidence!

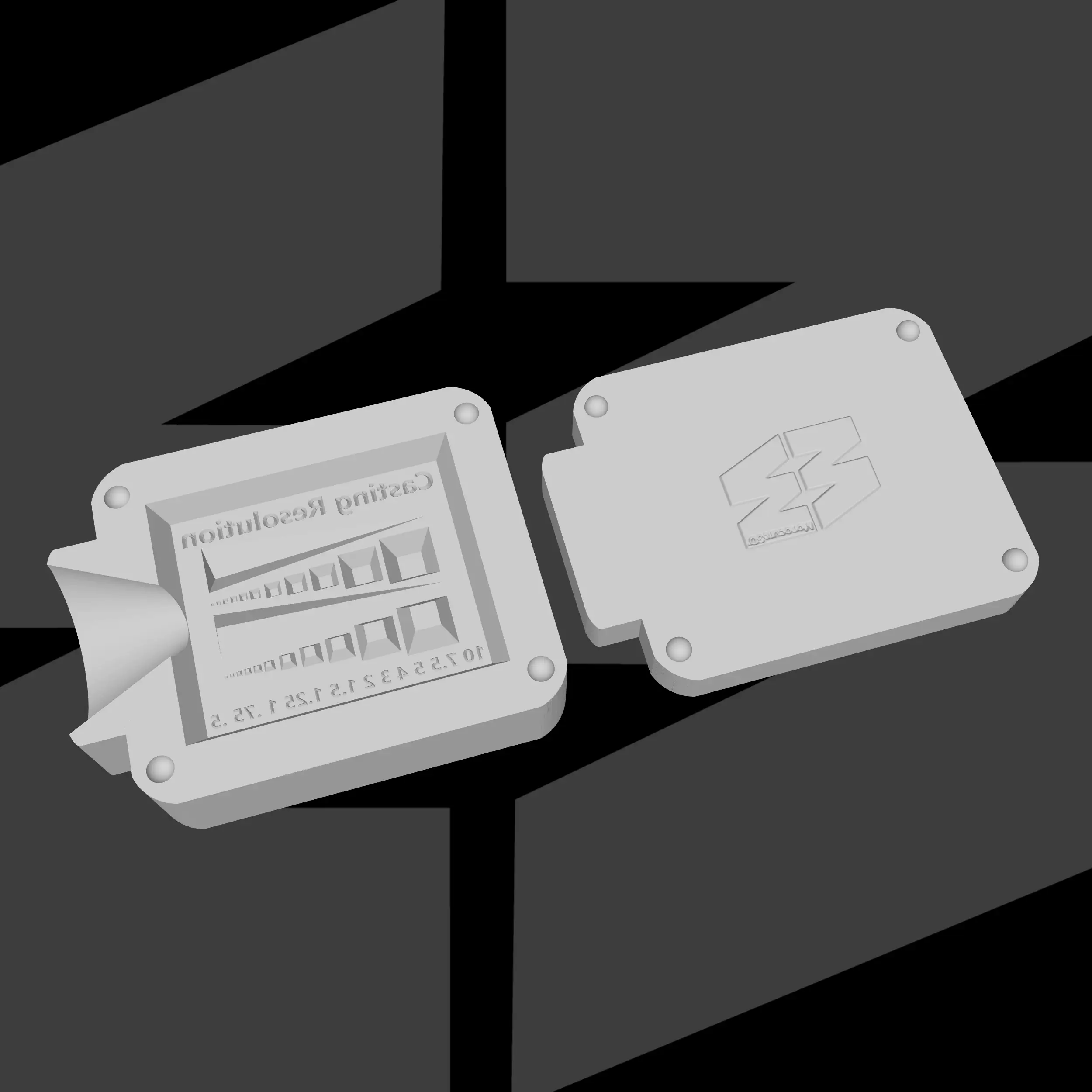

Casting Calibration

This calibration tool tests metal flow and detail accuracy when using ThermaCAST Direct Metal Casting Resin. It features positive and negative text, numbers, and shapes to assess fine detail reproduction. A successful cast should capture all features clearly, with no missing sections or holes—especially in the dovetails.

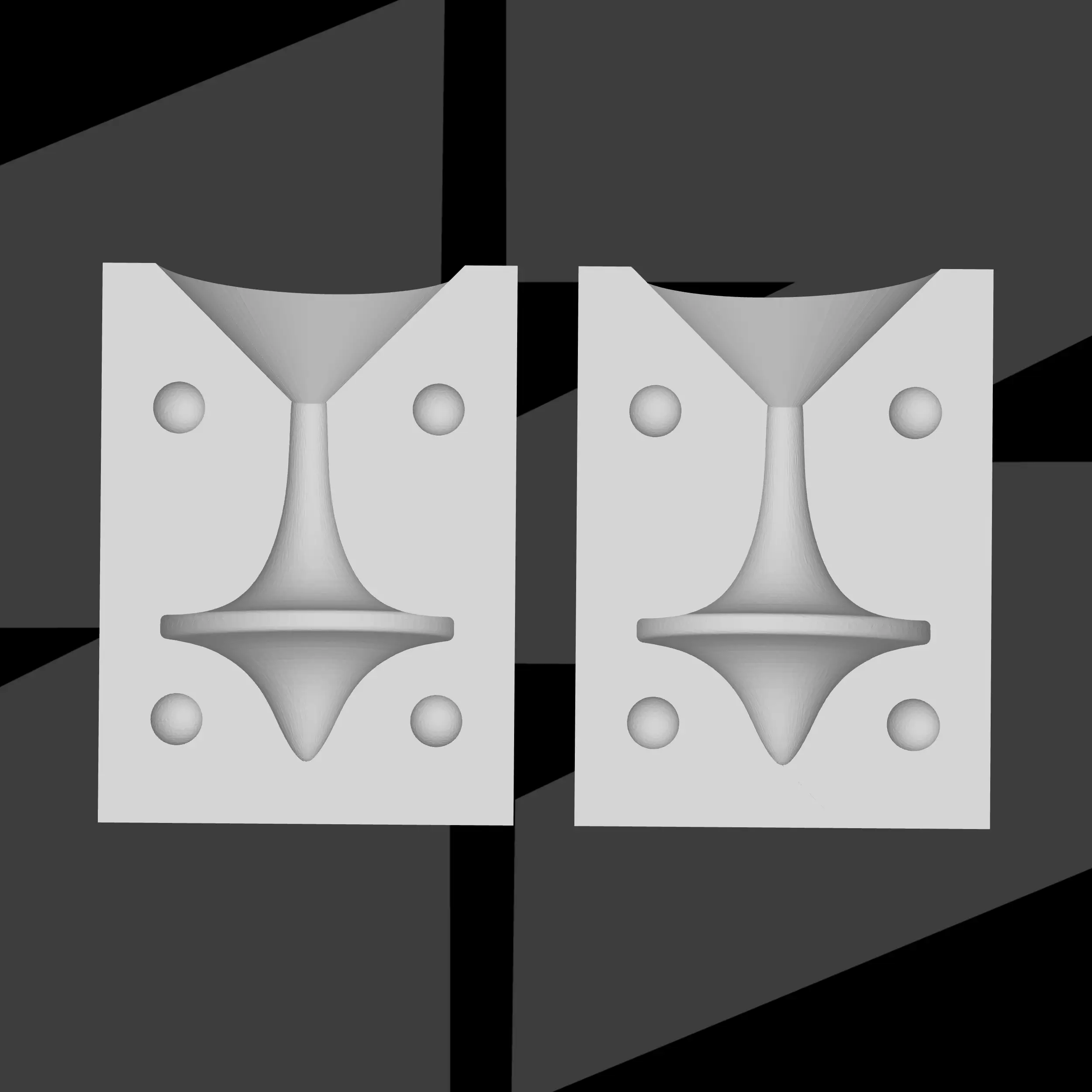

Spinning Top

This STL file provides a mould for casting a precision-balanced spinning top using ThermaCAST Direct Metal Casting Resin. Designed to test metal flow and fine detail reproduction, it ensures smooth casting with clean edges and no voids. Ideal for demonstrating casting accuracy and achieving a functional, well-weighted result.

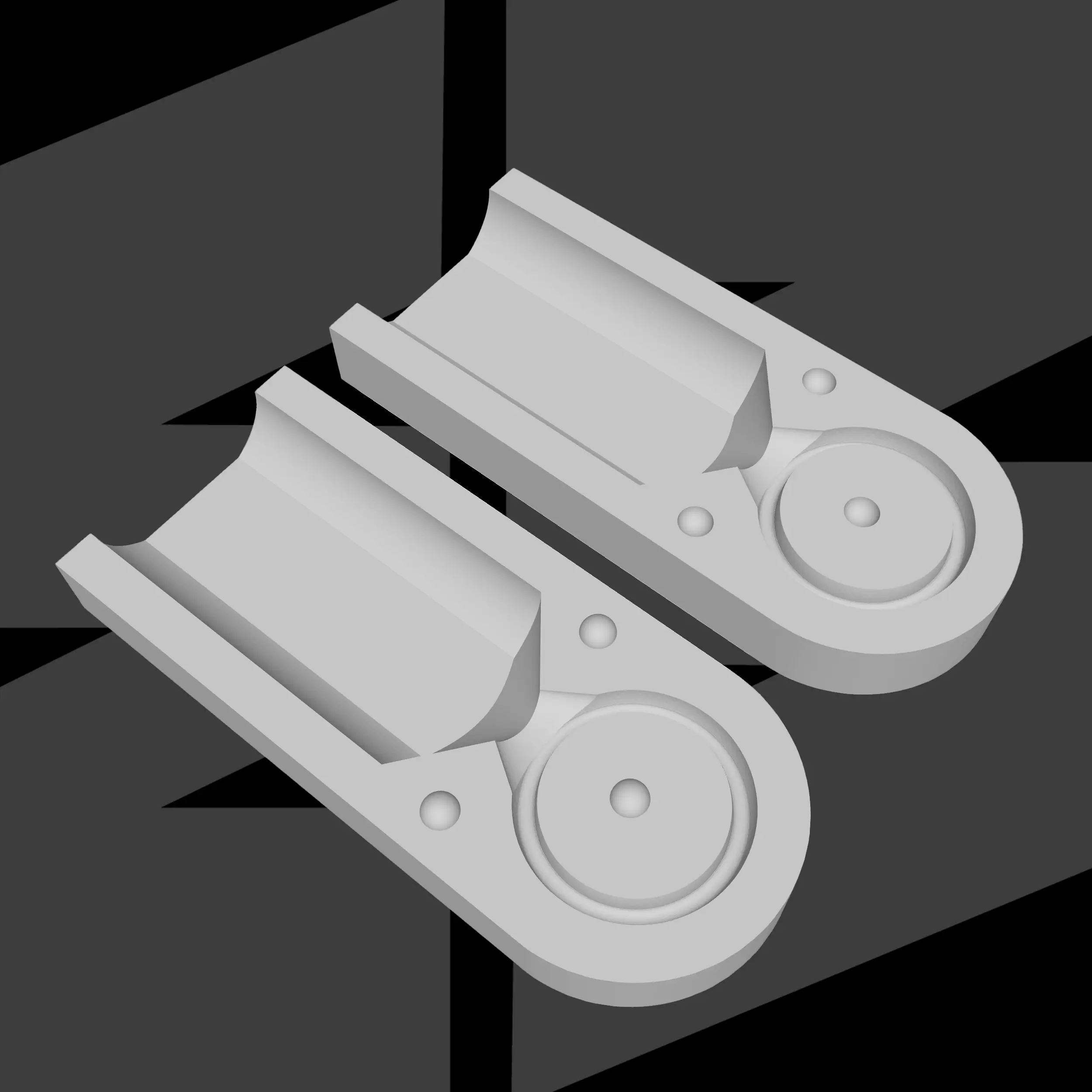

Simple Ring

A straightforward yet effective test piece for casting with ThermaCAST Direct Metal Casting Resin. This simple ring design allows you to evaluate metal flow, surface finish, and dimensional accuracy. Ideal for beginners and professionals looking to refine their casting setup.

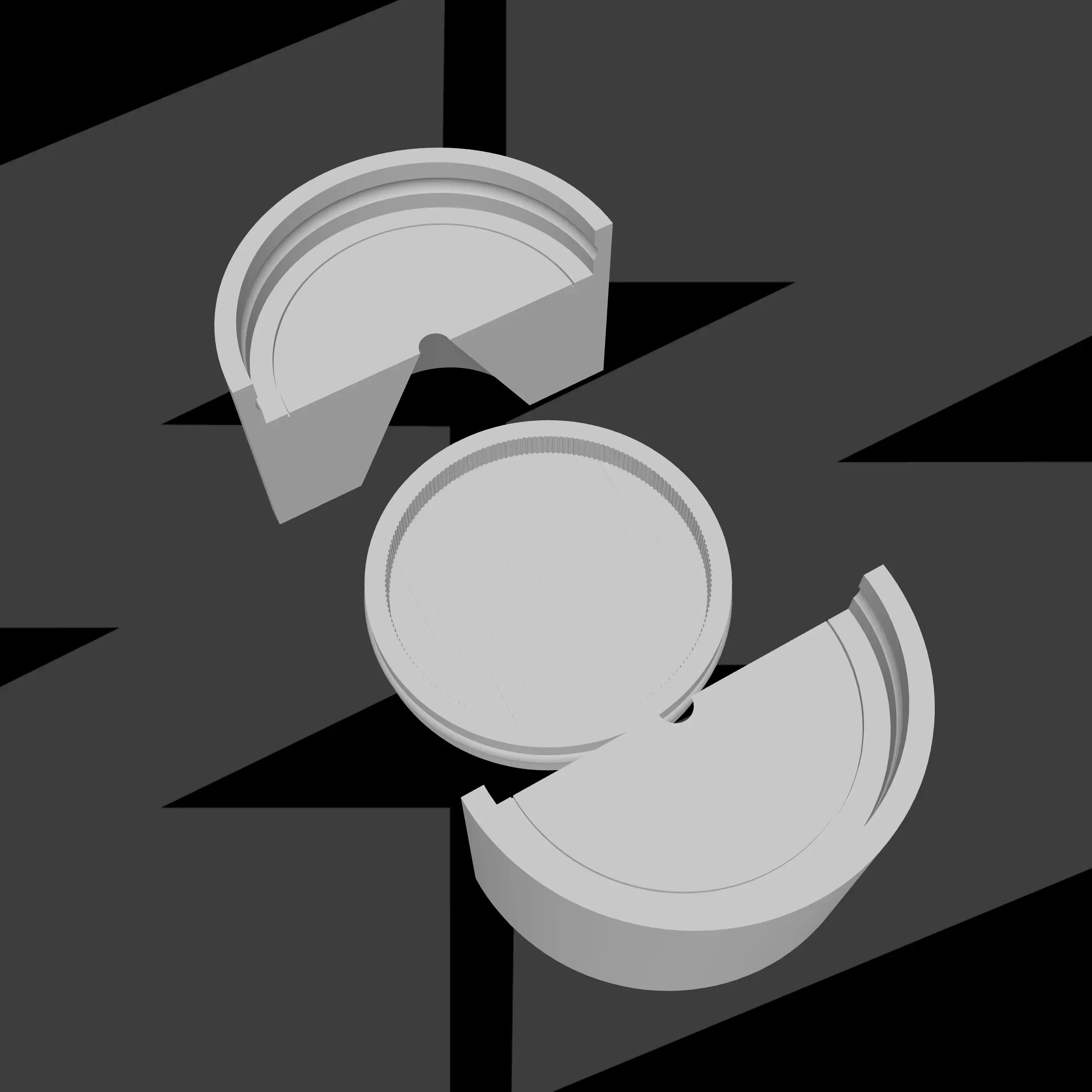

3-Part Blank Coin

This STL file features a three-part blank coin mould, perfect for testing metal flow, detail retention, and surface finish when using ThermaCAST Direct Metal Casting Resin. The modular design allows for easy customisation, making it ideal for prototyping coins, medallions, or tokens with crisp, well-defined edges.

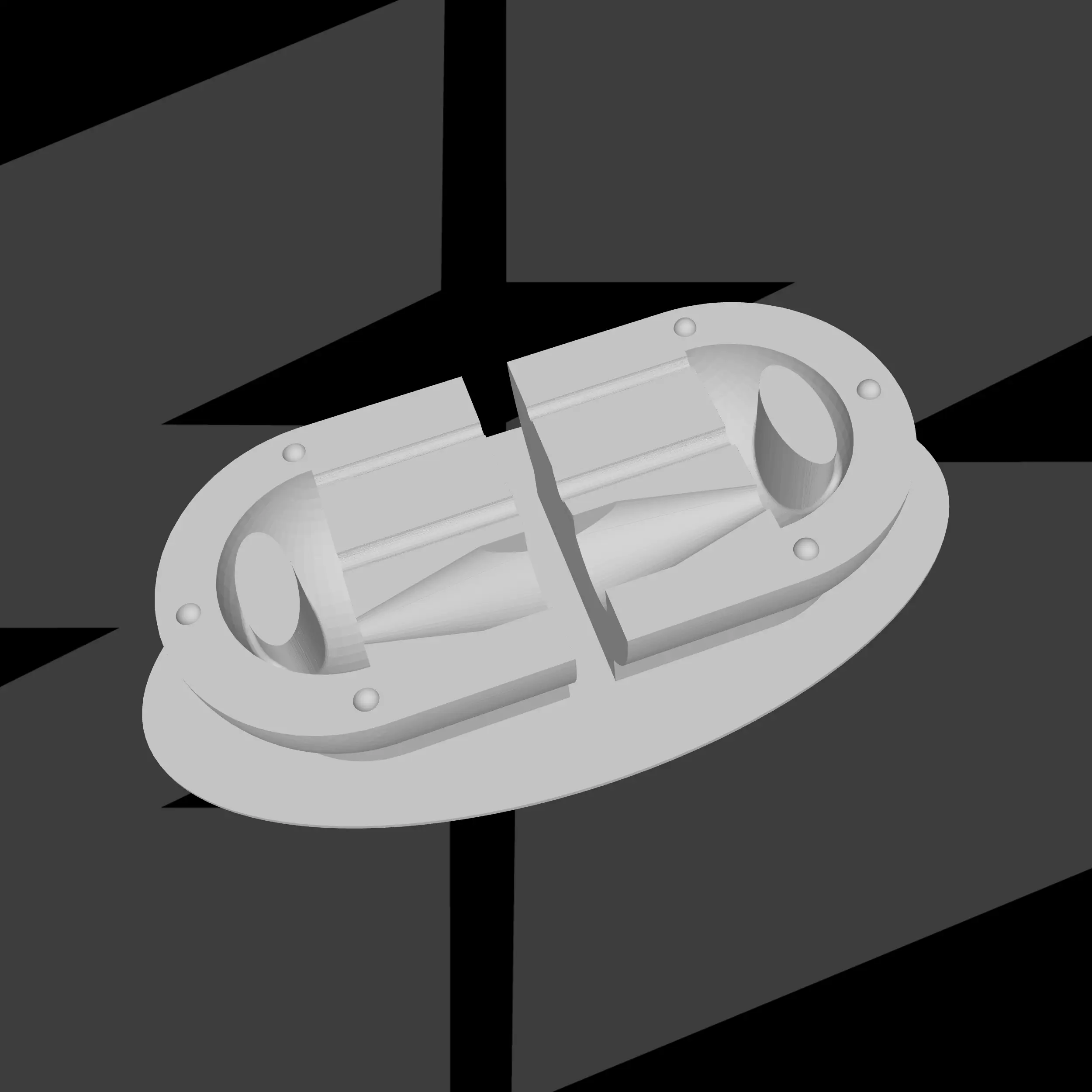

Fidget Spinner

This STL file provides a mould for casting a balanced fidget spinner using ThermaCAST Direct Metal Casting Resin. Designed to test metal flow and fine detail retention, it ensures smooth edges and accurate bearing fitment. Perfect for refining your casting process while creating a functional, high-quality spinner.

Double-sided Ingot

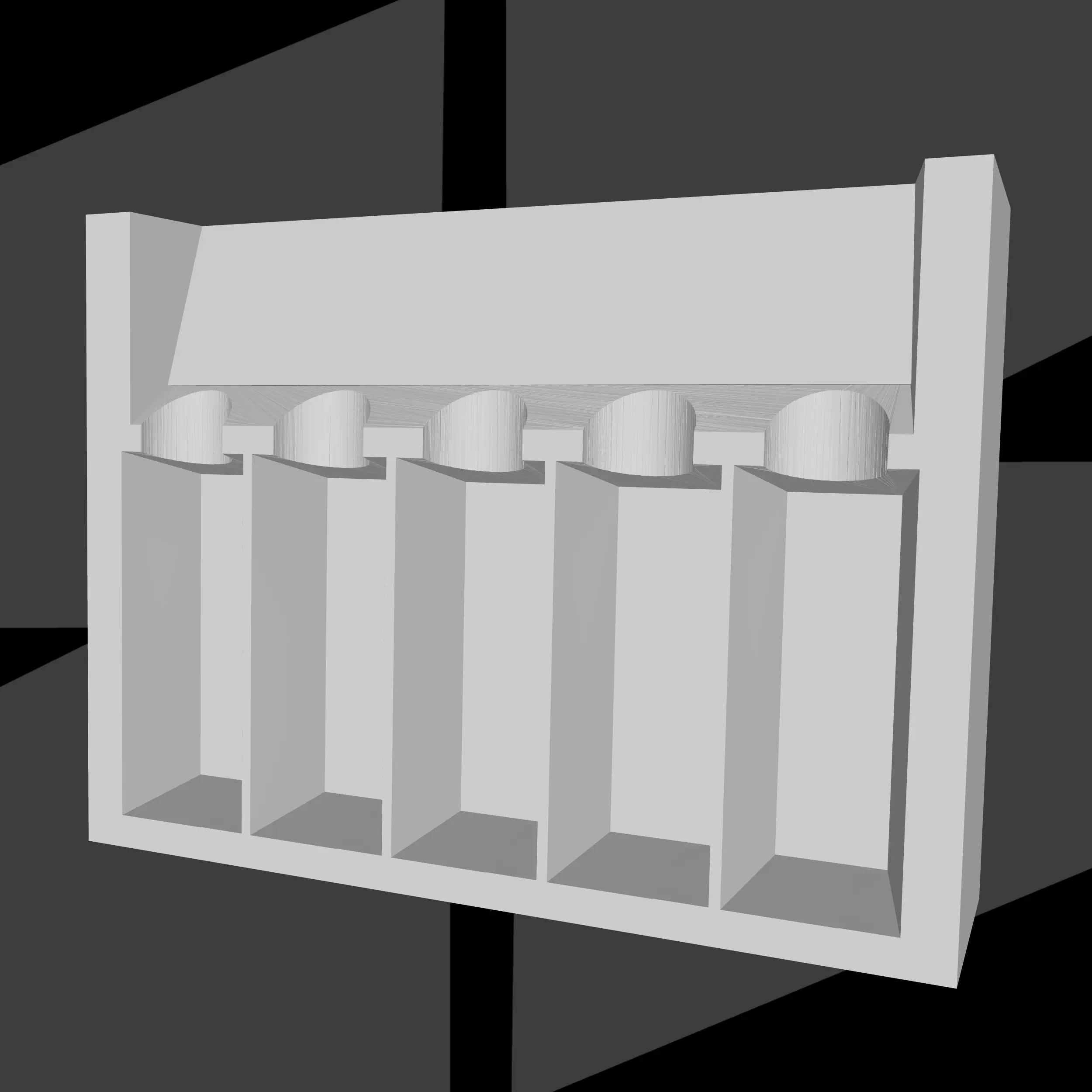

This STL file includes a mould for casting ten double-sided ingots, allowing you to test metal flow, surface finish, and repeatability using ThermaCAST Direct Metal Casting Resin. Designed for efficient multi-piece casting, each ingot captures fine details on both sides, ensuring clean, consistent results with no voids or defects.

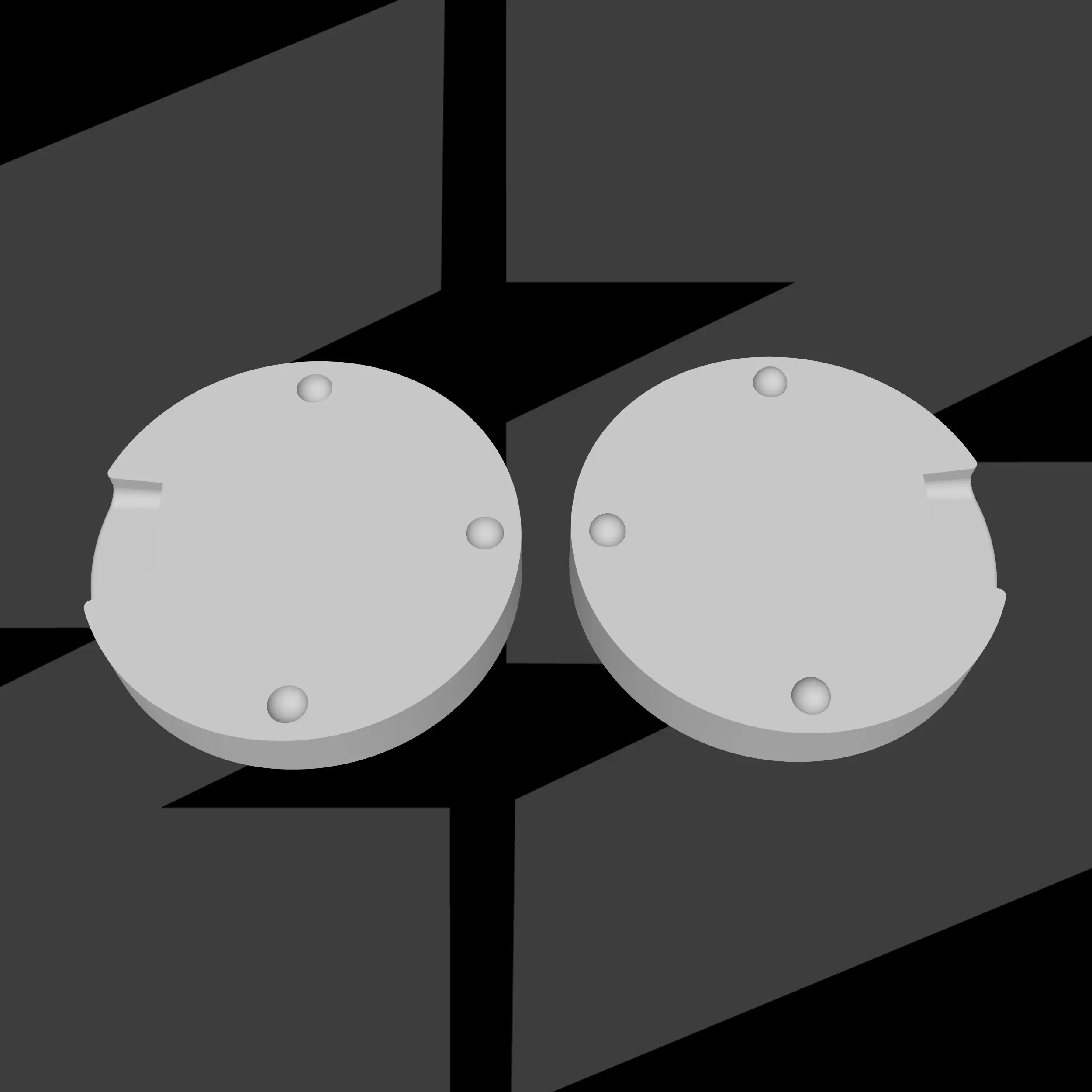

2-Part Round Blank

This versatile two-part blank mould is perfect for casting customisable round pieces using ThermaCAST Direct Metal Casting Resin. Ideal for testing metal flow and achieving a smooth, detailed finish, it provides a solid foundation for creating custom coins, tokens, or medallions. A great starting point for personalised casting projects.

Simple Knob

This STL file provides a mould for casting a sturdy, functional knob using ThermaCAST Direct Metal Casting Resin. Designed to test metal flow and surface finish, it ensures smooth edges and precise detail reproduction. Ideal for creating custom knobs for tools, appliances, or machinery.

How to Use These 3D Models for Metal Casting

Using these free 3D models with ThermaCAST Direct Metal Casting Resin allows you to refine your casting process, ensuring optimal metal flow, fine detail retention, and clean, defect-free results. Follow these steps to get the best performance from your prints and casts:

1. Download & Prepare the STL File

- Select the STL model you want to print from our free download collection.

- Open the file in your preferred slicing software (e.g., Lychee, Chitubox, or PrusaSlicer).

- Ensure the model is correctly scaled to match your casting requirements.

2. Print Using ThermaCAST Resin

- Use a DLP or MSLA 3D printer with ThermaCAST Direct Metal Casting Resin for best results.

- Dial in optimal exposure settings to capture fine details and ensure a strong, clean print.

- Print flat on the build plate to maintain accuracy and prevent distortion.

3. Post-Processing & Curing

- Wash your print in ResinAway or IPA to remove excess resin.

- Post-cure the printed part under UV light for at least 1 hour to fully harden the structure.

- Inspect the print to confirm that all details are intact before moving to the casting stage.

5. Pouring the Metal & Finishing

- Melt your chosen metal and pour it into the mould at the appropriate temperature for a complete fill.

- Dust your mould with a release agent such as real Talc or graphite powder.

- Allow the metal to “freeze” before carefully opening the mould.

- Polish and finish your cast part as needed to enhance its final appearance.

Following these steps, you can achieve highly detailed, accurate, and repeatable metal castings using our free 3D models and ThermaCAST Direct Metal Casting Resin. Start experimenting today to refine your process and create stunning metal parts!