HEAT RESISTANT | HIGH PRECISION | PRESSURE FORM | VACUUM FORM | ODOURLESS | EASY RELEASE

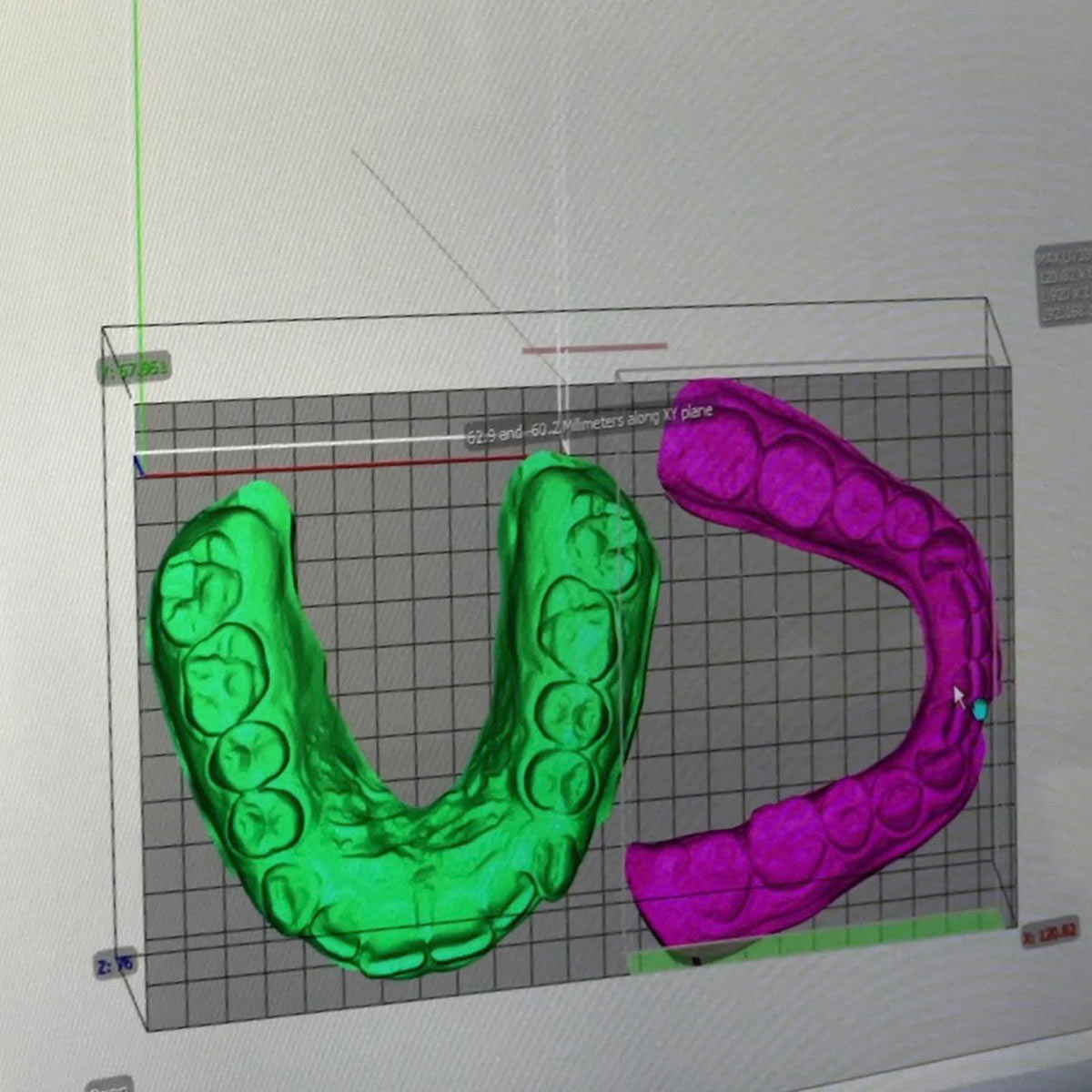

PRECISION THERMO FORMING

Thermo Heat Resistant Resin was developed for Pressure and Vacuum forming. These are two essential processes used in the production of 3D-printed dental models. Pressure forming involves the application of air pressure to a 3D printed model to fill in the details and create a more accurate and realistic representation of the desired model. Vacuum forming, on the other hand, uses a vacuum to suck the material onto the model and create a more detailed and accurate model. Both processes are used to create dental models that are accurate, durable, and aesthetically pleasing. These processes are made even more accessible and reliable using a specially designed 3D printing resin, like Monocure 3D THERMO™ Heat Resistant Resin. With superior heat resistance and pressure vacuum forming, Monocure 3D THERMO™ Heat Resistant Resin is the perfect choice for creating 3D-printed dental models.

THE THERMO™ RESIN ADVANTAGE

High Heat Resistance (120°C)

Specially designed to provide superior heat resistance, making it the perfect choice for Models that need to stand up to higher temperatures.

High Precision

THERMO™ Heat Resistant Resin is designed to provide high precision, allowing for detailed and dimensionally accurate 3D printed models.

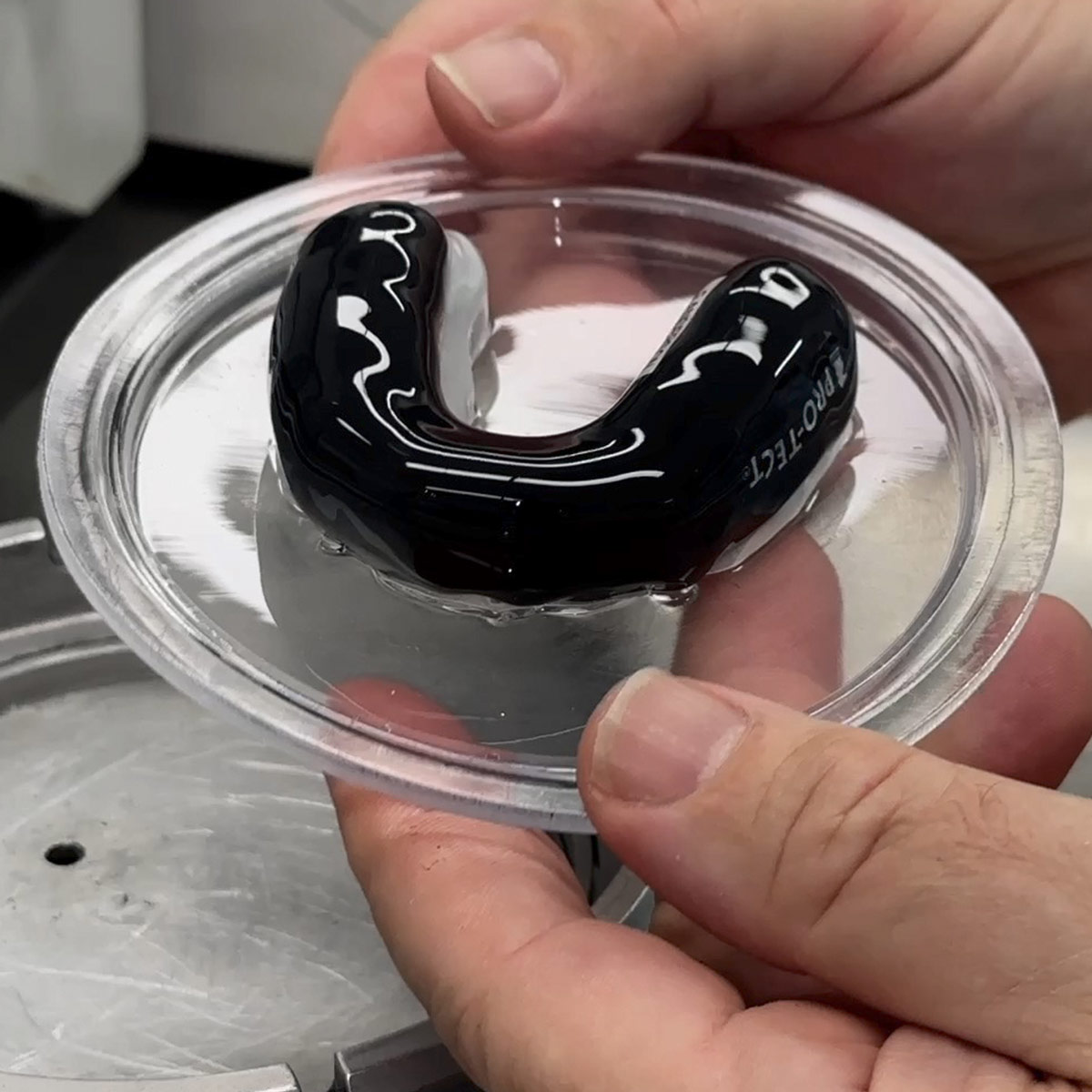

'Easy Release'

This resin is designed with an 'easy-release' formula, making it simple and easy to release mouth guards and aligners from the model after forming.

Multi-compatible formulas

This Resin is designed to be compatible with DLP and MSLA 3D printing technologies, making it perfect for high-quality results with either technology.

About THERMO™ Heat Resistant Resin

Monocure 3D THERMO™ Heat Resistant Resin is an innovative 3D printing resin perfect for projects requiring superior heat resistance and pressure vacuum forming. This resin is designed for both MSLA and DLP technologies, is easy to print, and boasts a smooth finish with an ‘easy–release‘ formula.

With excellent accuracy, it can print with higher speeds and lower failure rates than competitors. The resin is designed to suit layer heights from 10 to 100 microns and has a low odour. With Monocure 3D THERMO™ Heat Resistant Resin, you can create models easily and confidently, knowing that it is resistant up to 120C.

Which THERMO™ formula Suits your 3D Printer?

THERMO™ Heat Resistant Dental Resin is available in two formulas. Since DLP printers output more power than MSLA, we have a version to cover both system types.

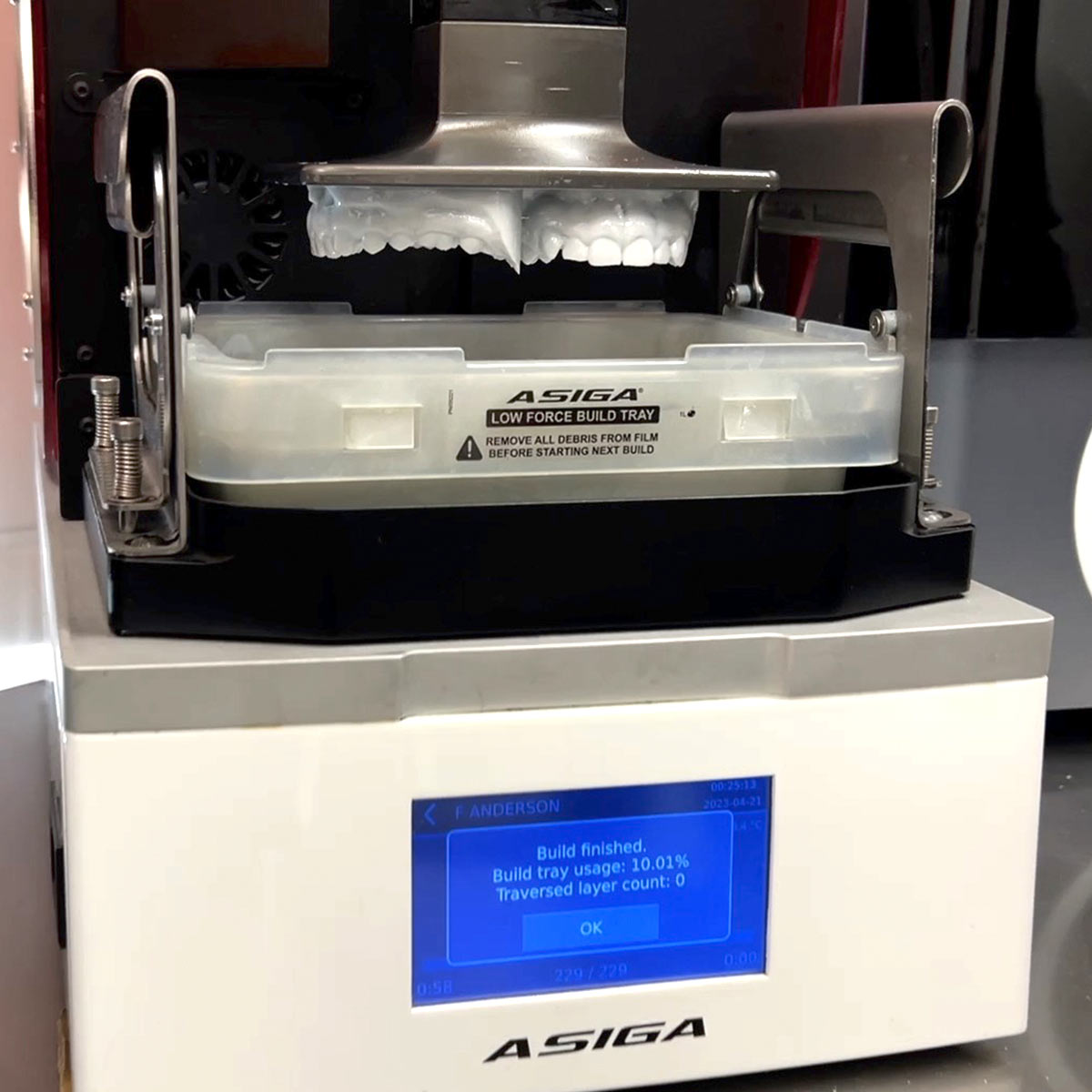

Choose the DLP formula if your printer uses a projector module (DLP) to expose the layers. These include brands and models such as the MoonRay, SprintRay, Peopoly Moai, Asiga UV-Max & Pro 4K, Phrozen Make, B9 Creator, Flashforge Hunter, XYZ Nobel, and Kudo Titan.

If your 3D printer uses an LCD screen and a LED array (MSLA) to expose the layers, you must use our regular MSLA formula. These include Anycubic, Phrozen, Creality, Elegoo, Epax, Peopoly, Prusa, Uniz, Wanhao, WOW SparkMaker & Kelant.

If your printer is not listed here, please Contact Us.

THERMO™ PRINTING TIPS

We recommend positioning the model flat on the build plate without supports or hollowing the model.

Post-curing a 3D-printed model is essential before pressure or vacuum forming. It ensures that the model is sufficiently cured and ready to withstand the pressure and heat of the thermo-forming process.

A calibration model is an effective way to dial in a 3D resin printer for use with our THERMO™ Resin, ensuring the printer & resin work together to produce highly-accurate models.

To ensure the model is properly cleaned, we recommend RESINAWAY® to remove any trapped resin that can cause dimensional issues.

The Missing Beginners Guide

Introducing the Revised Dental Edition: A comprehensive guide that covers the fundamentals of 3D printing with resin, featuring expert insights, tips, and tricks from industry professionals. This edition also provides a detailed analysis of various dental resins and printers and guidance for troubleshooting common issues.

This essential resource is designed to optimize your dental 3D printing experience. Lab technicians and dentists alike can quickly and effortlessly familiarize themselves with the latest technologies and techniques in 3D dental printing. The guide offers valuable advice on maximizing the potential of this innovative technology. With the support of this indispensable guide, anyone can confidently and rapidly become a dental 3D printing expert.

Authored by Charlie Anderson & Edited by Greg Baker

THERMO™ - PHYSICAL PROPERTIES (MSLA)

SKUs

M/THM-4006LGY

Colour(s)

Light Grey (RAL7035)

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1.5-3 seconds per layer (Monochrome LCD)

Storage

Dark, cool & dry place

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible MSLA Printers

Anycubic

Phrozen

Creality

Elegoo

Epax

Peopoly

Prusa

Uniz

Wanhao

WOW SparkMaker

Kelant

Not Listed – Contact Us

THERMO™ - PHYSICAL PROPERTIES (DLP)

Product Code(s)

M/THD-4006LGY

Colour(s)

Light Grey (RAL7035)

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1-3 seconds per layer

Storage

Dark, cool & dry place.

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible Printers

Asiga

SprintRay

Peopoly

MoonRay

Phrozen Make

B9 Creator

Flashforge Hunter

XYZ Nobel

Kudo Titan

Not Listed – Contact Us

Are you using Dental 3D Printer Resin for work?

Are you interested in becoming a Monocure 3D Reseller? Please fill in our online Application Form.

Do you work in Education, Government, or have your own Business? Fill in the application Form to see if you qualify for a Wholesale account.

If you like keeping up with the latest 3D printing news, then please subscribe to our Youtube Channel Monocure 3D ProTips and join the fun?