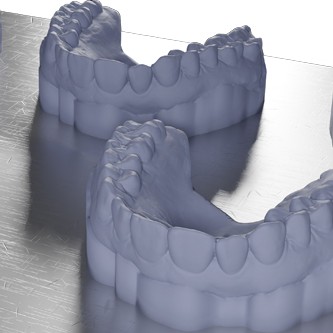

Study models | Diagnostic models | Implant models | Wax-up models | Presentation models | Retainer models

Discover The Study Model Advange

Rapid Speed

Fast printing with high accuracy. No shrinking or warping formulation. Fast layer curing means jobs are done more quickly.

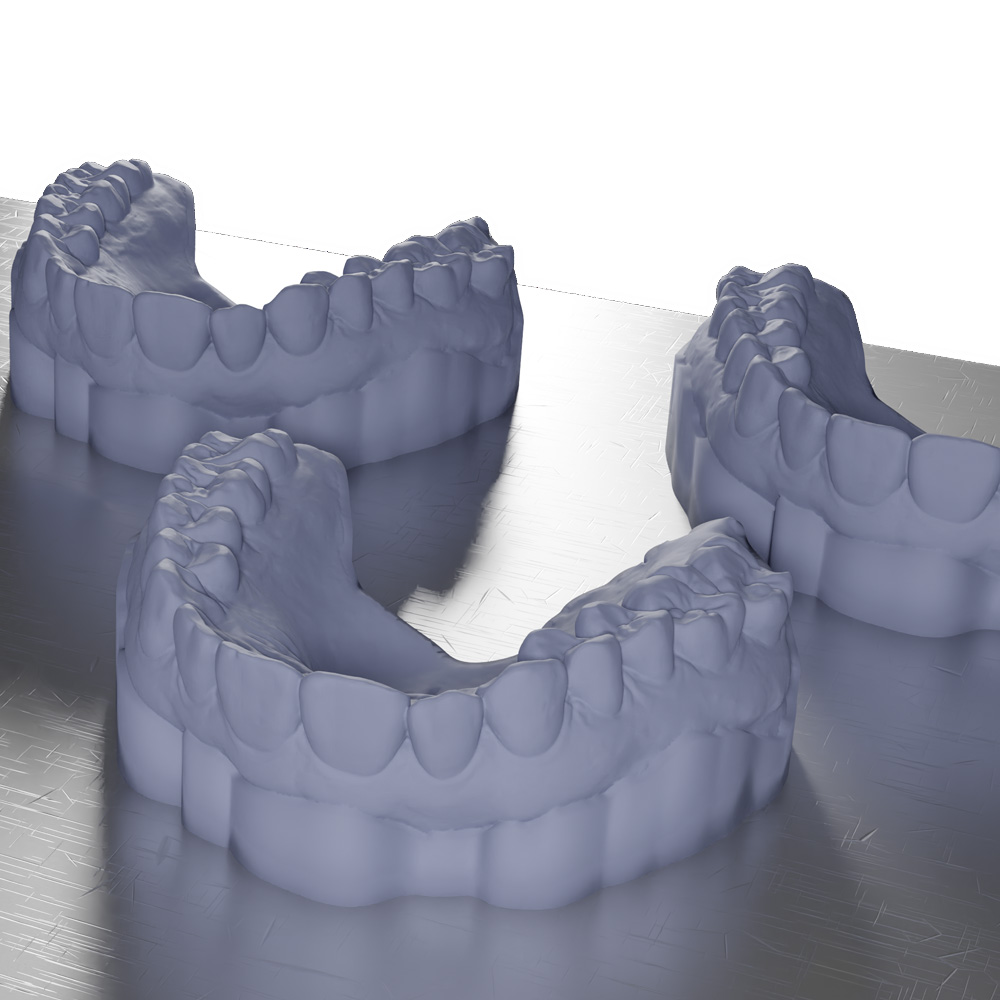

Gypsum-like Texture

STUDY™ resin has a high level of opaqueness, with a smooth gypsum-like matte surface finish that is less stressful on the eyes.

3 Popular Colours

Our Dental Model Resin is available in 3 colours: Grey, Tooth & Slate. These are suitable for all general-purpose dental model work.

MSLA & DLP formulas

Choose the formula that is best suited to work with your 3D resin printer. Find your printer settings here.

Developed by Dental Professionals

All our 3D Printer Resins are developed, manufactured and despatched from our facility in Sydney, Australia.

STUDY™ Dental model resin is based on our original epoxy Dental Model formula. With the assistance of leading dental industry professionals, the non-brittle formula was designed to have high dimensional stability and a gypsum-like matte texture for general-purpose 3D dental model processing.

Choose from two versions (MSLA & DLP) to work seamlessly with most resin 3D printers. The low failure & easy-to-print formula means all you have to do is pour and print. STUDY™ model resin is smooth, hard & accurate, and ideal for various dental processes.

Available in three custom dental colours: Tooth, Grey, and Slate Grey (perfect for 3D scanning). Sold in both 1ltr & 5ltr UV-safe bottles. Check our reseller list to find local supplies in your area to ensure you never run out.

*Monocure 3D STUDY™ resin is not approved for intraoral use.

STUDY™ Dental Resin Appliations

Diagnostic Models

A diagnostic model enables the 3D visualisation of a patient’s mouth and is useful for the prescription of further treatment, whether restorative, infection oriented, or otherwise.

Implant Models

Dental teeth implants start with a scan and model. With a properly designed and fitted dental implant, the patient will be able to chew and smile with complete confidence. This is a permanent and effective answer to missing teeth.

Wax-Up Models

Provides dental practitioners with a visual model of the patient’s dental situation and aids in the better preparation of the treatment plan. Most commonly used to display an end result and present it to the patient.

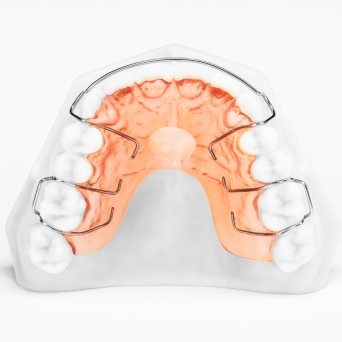

Retainer Models

A dental retainer is designed to hold your teeth in place after orthodontic treatment. During the active phase of the treatment, the bone and tissue that support the teeth break down, and the ligaments loosen, allowing the teeth to move.

Which STUDY™ formula Suits your 3D Printer?

STUDY™ Dental Model Resin is available in the popular colour Grey. Since DLP printers output more power than MSLA, we have a version to cover both system types.

Choose the DLP formula if your printer uses a projector module (DLP) to expose the layers. These include brands and models such as the MoonRay, SprintRay, Peopoly Moai, Asiga UV-Max & Pro 4K, Phrozen Make, B9 Creator, Flashforge Hunter, XYZ Nobel, and Kudo Titan.

If your 3D printer uses an LCD screen and a LED array (MSLA) to expose the layers, you must use our regular MSLA formula. These include Anycubic, Phrozen, Creality, Elegoo, Epax, Peopoly, Prusa, Uniz, Wanhao, WOW SparkMaker & Kelant. Please try the widget below to check the best resin for your 3D printer.

STUDY™ 3D Printing ProTips

Ensure the material is mixed well before each time you print. This should be done by shaking the bottle or stirring the resin in the VAT before each print. Unused resin can be filtered and returned to the bottle.

Removing the excess resin is an important part of the resin printing process. This ensures that there is no trapped resin that can affect the detail of the model. IPA can be used, but for the best results and a safer alternative, we recommend our ResinAway® cleaning solution.

Most 3D Printers & Resin materials are unique and require setting up before first-time use. We recommend that you dial-in new printers and resins using one of our handy calibration models.

After the washing process, post-curing any UV resin is vital. It helps remove any tackiness and completes the cross-linking process. This ensures the material is at its optimal mechanical properties as the final cross-linking occurs.

Need Help? Speak with Our Experts Today

STUDY™ dental resin is versatile and can be printed between 10 and 100-micron layer heights. To achieve the best results, 3D models should always be designed solid, if hollowing is required, ensure drain holes are included to remove any trapped resin.

Always print large flat areas on an angle to help with print deformation due to the adhesion to the FEP film. To assist with unsupported areas, ensure you use well-positioned, solid supports. We recommend you add a 1-2 seconds “wait after print” setting to allow the material to cool after curing before starting to lift the build plate.

Check our printer setting page to see if we have your printer listed to give you a good starting point. (Not all slicers have this setting, check with your software provider). Use a calibration model to dial in your printer with our resin.

We love to help! Please feel free to call us for assistance. Local manufacturing means local support. When you buy from us, you are not just buying a product. We have years of 3D printing and technical support experience.

STUDY™ - MECHANICAL PROPERTIES

Method Code: ASTM D638-14

Product: Monocure 3D STUDY™ Resin (50μm)

Acceptance Code: Supply Findings

Specimen Type: Retangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

3DDR-3978GY, 3DDS-3979GY

Cross-Sectional Area (mm2)

25.29

Max Force (kN)

1.64

Tensile Strength (MPa)

47

Elongation at Break

3.0

Young’s Modulus (GPa)

1.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

124

Max Flex Strain (mm/mm)

0.5

Shore Hardness (D)

75

Heat Deflection Temp

55°C @ 0.45MPa

Perfect Your Finish in Just 3 Steps

For best results after printing, use ResinAway® to remove uncured resin from the part. It cleans faster, better and lasts longer than IPA. It is non-flammable, doesn’t evaporate and has a pleasant scent. Follow the steps below to achieve the best finish for your 3D Printed dental models.

- Place part in a pre-wash bath filled with ResinAway® and use a soft brush to remove excess resin. Follow by placing the component into an ultrasonic cleaner with ResinAway® for 3-5mins to help remove the resin trapped in the finer detail.

- Ensure parts are dry by using compressed air or patting gently with a lint-free cloth before post-curing – Warning: leaving excess IPA or ResinAway® on parts might result in surface cracking.

- STUDY™ resin requires post-curing to reach its optimal mechanical properties. We recommend using a 405nm LED Ultraviolet light to post-cure the model. It is recommended to post-cure for a few minutes, then remove the excess ResinAway® by washing with fresh water. Then place it back in the curing chamber for at least 30 mins to improve the tensile strength of the resin.

STUDY™ - PHYSICAL PROPERTIES (MSLA FORMULA)

SKUs

3DDR-3978GY

Colour(s)

Grey

Viscosity

400cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

225nm to 420nm

Cure Speed

2-3 secs per layer with UV 405nm

Storage

Dark, cool & dry place.

Wash Up

RESINAWAY® or IPA

Compatible MSLA 3D Printers

- Anycubic

- Phrozen

- Creality

- Elegoo

- Epax

- Peopoly

- Prusa

- Uniz

- Wanhao

- SparkMaker

- Kelant

- Not Listed – Contact Us

STUDY™ - PHYSICAL PROPERTIES (DLP FORMULA)

SKUs

3DDS-3978GY

Colour(s)

Grey

Viscosity

400cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

225nm to 420nm

Cure Speed

1 – 3 secs per layer DLP UV 385-405nm

Storage

Dark, cool & dry place.

Wash Up

RESINAWAY® or IPA

Compatible Printers

- Asiga

- SprintRay

- Peopoly

- Moonray

- Phrozen Make

- B9 Creator

- Flashforge Hunter

- XYZ Nobel

- Kudo Titan

- Not Listed – Contact Us