Why Choose Monocure3D TENSILE™ Resin?

TENSILE resin is expertly formulated with a proprietary blend of advanced urethanes and epoxies designed to deliver exceptional tensile strength and long-lasting durability. This resin perfectly balances fine detail, strength, flexibility, and a smooth, hard surface finish.

Ideal for applications where rigidity and durability are paramount, TENSILE resin allows 3D-printed models to withstand stress and strain without becoming brittle. Once post-cured, the material can be machined, painted, or polished to achieve a professional finish, offering versatility for various projects.

Its low-odour formula makes TENSILE resin well-suited for use in confined spaces such as home offices, garages, or shared living environments, ensuring a more pleasant and user-friendly printing experience.

TENSILE™ Resin | Key Features

Extreme Tensile Strength

The advantage of producing parts with superior strength and durability, which can withstand high stress and impact, makes it ideal for applications in various industries.

Ultra-Accurate Printing

High-resolution 3D printing resin creates intricate, finely detailed parts and prototypes, making it a preferred choice in applications where precision is critical.

Long-Lasting Durability

Formulated to deliver extended lifespan and performance, ensuring your printed parts maintain their integrity over time.

Satisfaction Guaranteed

Our 100% money-back satisfaction guarantee ensures that if you are not completely satisfied with our product you can return it for a full refund.

Optimise Your Prints with TENSILE™ Resin

TENSILE Resin offers exceptional performance across various applications, supporting layer heights from 10 to 150 microns. For best results, models should generally be sliced as solid to maximise strength. If hollowing is required, include well-placed drain holes to prevent resin trapping and ensure efficient post-cleaning.

When positioning your model, angle it slightly on the build plate to minimise large flat surfaces that can cause suction forces against the FEP film. Use dense, carefully placed supports to stabilise unsupported areas and maintain structural integrity during printing.

TENSILE Resin requires optimised print settings tailored to its unique properties. Slower curing times may enhance final tensile strength. Use our calibration models on the website to fine-tune your printer and achieve consistent, high-quality results.

For further guidance, visit our printer settings page to see recommended settings for your specific printer model, offering a reliable baseline to dial in TENSILE Resin effectively.

Post-Processing Guide for TENSILE™ Resin

1. Cleaning the Print

After printing, use ResinAway® to remove uncured resin. Begin with a pre-wash bath and use a soft brush to clean the surface. For intricate details, place the part in an ultrasonic cleaner with ResinAway® for 3-5 minutes.

2. Drying the Part

Use compressed air or a lint-free cloth to dry the model. Warning: Leaving excess IPA or ResinAway® on the part may cause surface cracking. Ensure the part is completely dry before post-curing.

3. Post-Curing the Model

Post-curing is essential to achieve optimal properties. Use a 405nm LED UV light. Cure for a few minutes, rinse with fresh water, then cure for at least 30 minutes to enhance tensile strength. For maximum performance, cure for 2 hours. Properties will further improve over the next few days.

4. Surface Finishing

Apply paint to protect against external elements or machine, sand, or polish the model to create a tough, scratch-resistant surface.

TENSILE™ LIQUID PROPERTIES

SKUs

M/INT-4042C, M/INT-4014GY, M/INT-4044BK, M/INT-4043W

Viscosity

200cps @ 25°C(Brookfield RVT)

Odour

Negligible Characteristics

Active Solids

100%

Shelf Life

36 months

Optimal UV Cure

405nm

Particle Size

< 10um

Cure Speed

3.5 secs (approx)

Storage

Dark Cool & Dry Place

Wash Up

RESINAWAY® or IPA

TENSILE™ MECHANICAL PROPERTIES

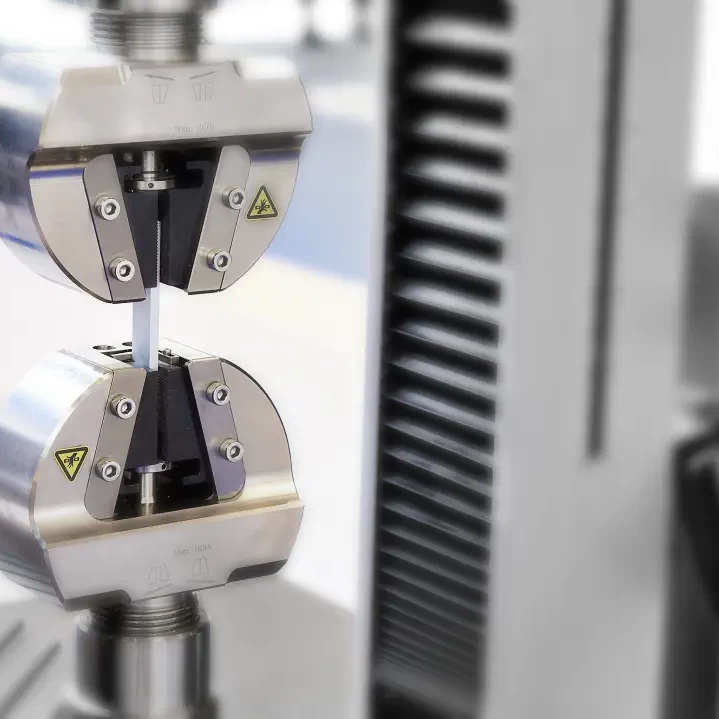

Method Code: ASTM D638-14

Product: Monocure3D TENSILE Resin (50μm)

Acceptance Code: Supply Findings

Specimen Type: Rectangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

M/INT-4042C, M/INT-4014GY, M/INT-4044BK, M/INT-4043W

Cross-Sectional Area (mm2)

25.21

Max Force (kN)

2.3

Tensile Strength (MPa)

86.7

Elongation at Break

2.5%

Young’s Modulus (GPa)

1.4

Flexural Band Span (mm)

89

Max Load Applied (N)

130

Flexural Stress (MPa)

125

Shore Hardness (D)

92

Heat Deflection Temp

64°C @ 0.45MPa