BioResin | High Performance, Skin-Safe & Low Odour

BioResin™ was developed to address the unique needs of users who experience sensitivities to standard 3D printing resins, including issues such as skin irritation, strong odours, or allergic reactions. This innovative formulation was adapted from our trusted BIO resin, which has a proven track record in the demanding dental industry. By leveraging this biocompatible foundation, BioResin™ achieves an exceptional balance between professional-grade performance and user safety, making it a standout option for sensitive users.

Designed with versatility in mind, BioResin™ is ideal for home and industrial applications, offering a safe and reliable solution across diverse settings. Its low-odour and skin-friendly formulation makes it particularly well-suited for use in confined spaces, shared environments, or anywhere user comfort is a priority. Whether you’re a hobbyist, educator, or professional, BioResin™ ensures consistent, high-quality results without compromising the health and well-being of those handling it.

By choosing BioResin™, you’re selecting a product that puts your safety first, enabling you to focus on your creativity or professional projects with confidence and peace of mind.

Key Features of BioResin™

Skin-Safe Formulation

Specifically designed for users with sensitive skin, odour sensitivities, or allergy concerns, ensuring a safer and more comfortable 3D printing experience.

Low-Odour and VOC

It is completely free from harsh or overpowering smells, making it the perfect choice for use in confined areas, shared workspaces, or environments where air quality is a priority.

High-Precision

Delivers reliable, high-quality 3D prints with excellent detail, precision, and consistency, ensuring every project meets professional standards while being safe to use.

Versatile Applications

Perfect for home use, educational settings, and a wide range of industrial projects, offering versatility and reliability across various 3D printing applications.

BioResin™ Resin Colour Options

BioResin™ Grey

Grey’s neutral tone enhances visibility and detail, making it an excellent choice for prototypes and functional models. Its muted shade provides exceptional contrast, highlighting intricate features and enabling easy inspection of fine details. Grey also serves as an ideal base for painting, offering a consistent surface for adding custom finishes. This versatile colour is perfect for design iterations, architectural models, and engineering prototypes.

BioResin™ Almond

Almond’s warm, natural tone adds an organic aesthetic to 3D prints, making it an excellent option for artistic creations, figurines, or models that benefit from a softer, more approachable appearance. The subtle shade reduces glare under bright lights, improving visibility during the printing and inspection. Almond is also highly forgiving for showcasing surface textures and is well-suited for applications where the result needs to exude a refined, elegant finish.

BioResin™ Clear

Clear offers good transparency, ideal for creating parts where internal structures need to be visible or for functional prototypes requiring light transmission. It is perfect for applications like lenses, fluid flow models, or showcasing internal mechanisms. The clear finish allows easy post-processing, such as polishing, to achieve an even higher transparency. This versatile option is also well-suited for creative and decorative projects, offering endless possibilities for innovation.

Expert Tips for Printing with BioResin™

Prepare Your Resin

Ensure the resin is at room temperature and well-mixed before use. Shake the bottle thoroughly to achieve consistent results across your prints.

Calibrate Your Printer

Use calibration models to fine-tune your printer settings for BioResin™, ensuring high accuracy and precision.

Post-Cure for Durability

After cleaning, post-cure your models under 405nm UV light for 20–30 minutes to enhance strength and long-term stability.

Use Supports Strategically

Angle models on the build plate and use well-placed, dense supports to prevent warping and ensure flawless prints.

Optimising Your Prints with BioResin™

BioResin™ delivers exceptional performance across various applications, supporting layer heights from 10 to 200 microns to suit detailed, larger-scale prints. For optimal results, models are best printed solid, but if hollowing is required, ensure strategically placed drain holes to prevent resin from becoming trapped and to improve post-print cleaning.

When preparing your model, angle it slightly on the build plate to reduce large flat surfaces that may cause adhesion issues with the FEP film. Use dense, well-placed supports to secure overhangs and unsupported areas, ensuring structural integrity throughout the print.

BioResin™ is formulated for efficiency, often requiring slightly faster exposure settings than standard resins. Adjust your printer settings to match these requirements, and take advantage of the calibration tools available on our website to fine-tune your setup.

For specific guidance tailored to your printer, visit our dedicated printer settings page, where you’ll find detailed profiles to help you achieve the best results with BioResin™.

Post-Processing Guide for BioResin™

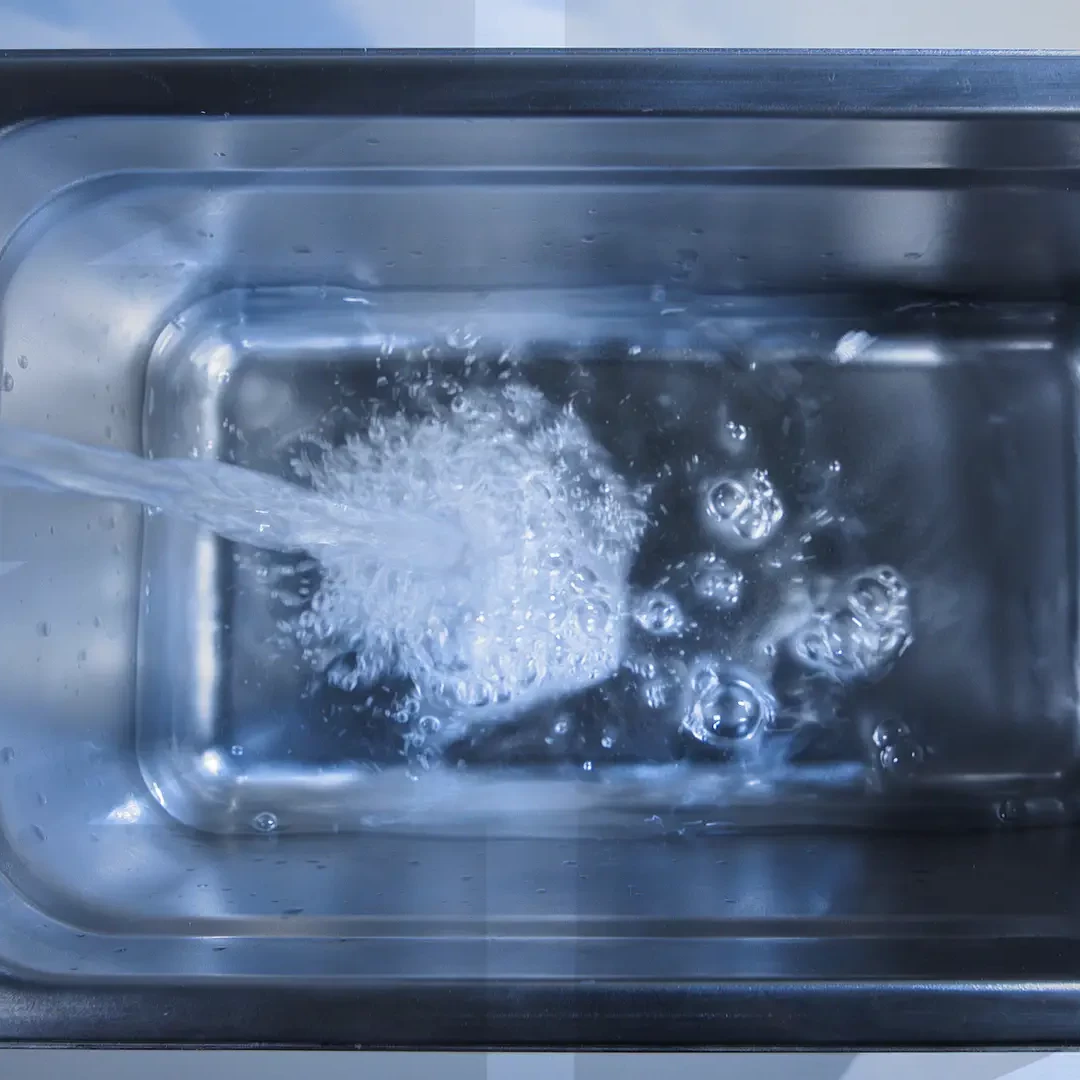

1. Cleaning with ResinAway®: After printing, immerse your model in a pre-wash bath filled with ResinAway® to remove uncured resin. Use a soft brush to gently clean the surface, ensuring intricate details are not damaged. For complex designs or hard-to-reach areas, place the model in an ultrasonic cleaner filled with ResinAway® for 5-10 minutes for a thorough clean.

2. Drying the Model: Once cleaned, ensure the model is completely dry by using compressed air to blow off any remaining liquid or patting it gently with a lint-free cloth. Avoid leaving residual ResinAway® or moisture on the model, as this can lead to surface imperfections or cracking during curing.

3. Post-Curing for Strength: Place the model in a curing chamber equipped with a 405nm LED UV light. Begin with a brief exposure to cure the surface evenly. Rinse the model with fresh water to remove any remaining ResinAway® residue before continuing for optimal results. Return the model to the curing chamber for at least 30 minutes to enhance its mechanical properties, including tensile strength and durability.

4. Finishing Touches (Optional): For projects exposed to external elements, consider applying a protective paint or coating to improve longevity. BioResin™ models can be machined, sanded, or polished to achieve a smooth, scratch-resistant surface, making them suitable for professional and display-ready applications.

BioResin: Liquid and Mechanical Properties at a Glance

MECHANICAL PROPERTIES

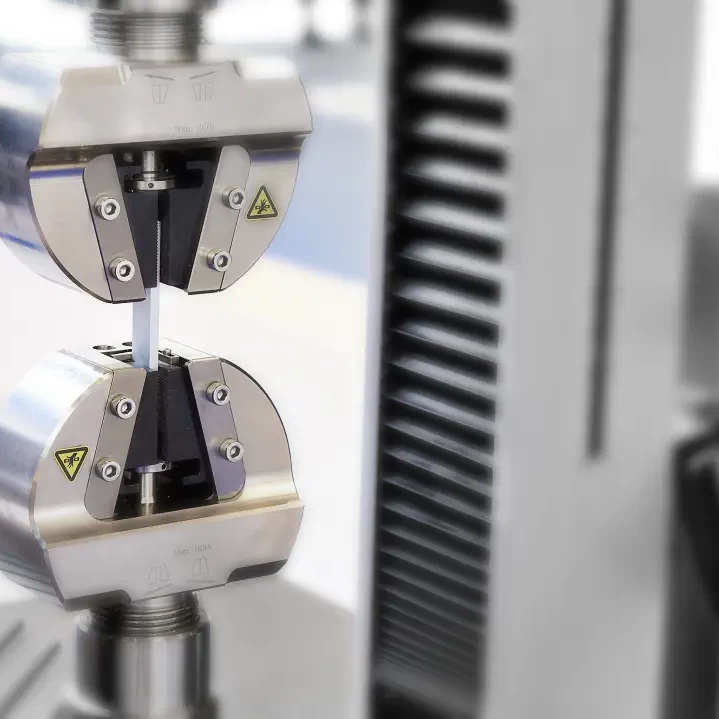

Method Code: ASTM D638-14

Product: Monocure3D BioResin (50μm)

Acceptance Code: Supply Findings

Specimen Type: Rectangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

M/BIO-4149C, M/BIO-4151GY, M/BIO-4150AL

Cross-Sectional Area (mm2)

25.29

Max Force (kN)

1.64

Tensile Strength (MPa)

49

Elongation at Break

3.0

Young’s Modulus (GPa)

1.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

124

Max Flex Strain (mm/mm)

0.5

Shore Hardness (D)

87

Heat Deflection Temp

130°C @ 0.45MPa

LIQUID PROPERTIES

SKUs

M/BIO-4149C, M/BIO-4151GY, M/BIO-4150AL

Colour(s)

Grey, Almond, Clear

Viscosity

700cps @ 25°C (Brookfield RVT)

Odour

None

Shelf Life

36 months

Active Solids

100%

UV Cure

405nm (optimal)

Cure Speed

2.5 secs

Storage

Dark cool & dry place

Wash Up

RESINAWAY® or IPA