RAPID MODEL RESINS

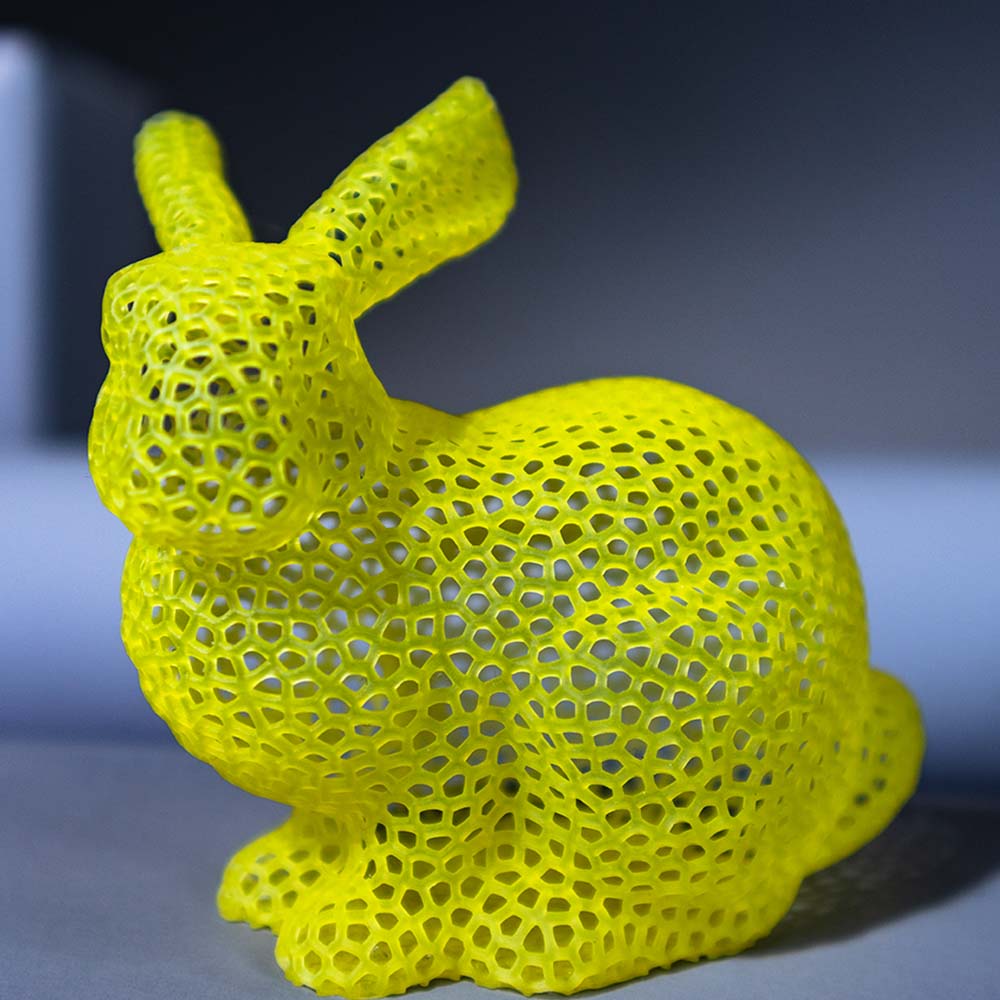

Our famous Rapid Model Resins are a unique, epoxy-based system that creates models with a hard surface finish without the brittleness you would expect. It was specially developed in Australia for MSLA 3D printers that use an LCD screen and LED array to print 3D models.

Prototyping | Miniatures | Display models | Architecture models | Hobby models

RAPID MODEL RESIN FEATURES

Incredible Detail

A unique, epoxy-based resin prints at high detail 3d printing resin without brittleness.

Easy to Use

Give the bottle a shake, and the Rapid Model resin is ready to pour and print. No heating required.

Ultra Fast

Rapid Model Resins can print fast on all MSLA 3D printers, with 2 -3 second normal layers on most Monochrome 3D printers.

Huge Colour Range

Need some colour? Don’t print in just black and white. Available in various deep solid colours to make your models stand out.

About Rapid Model Resins

Monocure 3D Rapid Model Resins were initially developed with MSLA printers that use LED arrays to cure the resin. The unique, epoxy-based system creates models that process a hard surface finish without the brittleness you would expect.

This resin is easy to use; give the bottle a quick shake, then pour and print! The typical normal layer durations for an MSLA printer are approx. 2-3 seconds in a printer with a monochrome LCD Screen.

Our Rapid Resins should be post-cured for at least 20-30mins after cleaning. This ensures that the model will not crack or split over time. Please check our printer settings page for all the information to help you dial in your printer with our resin.

RAPID MODEL PRINTING TIPS

Ensure the resin is mixed well by shaking the bottle before every use.

Always ‘dial in’ your Printer using our Calibration Models.

For best results, clean Models with our ResinAway® solution.

To reduce the yellowing, try to Post-Cure using 405nm UV only.

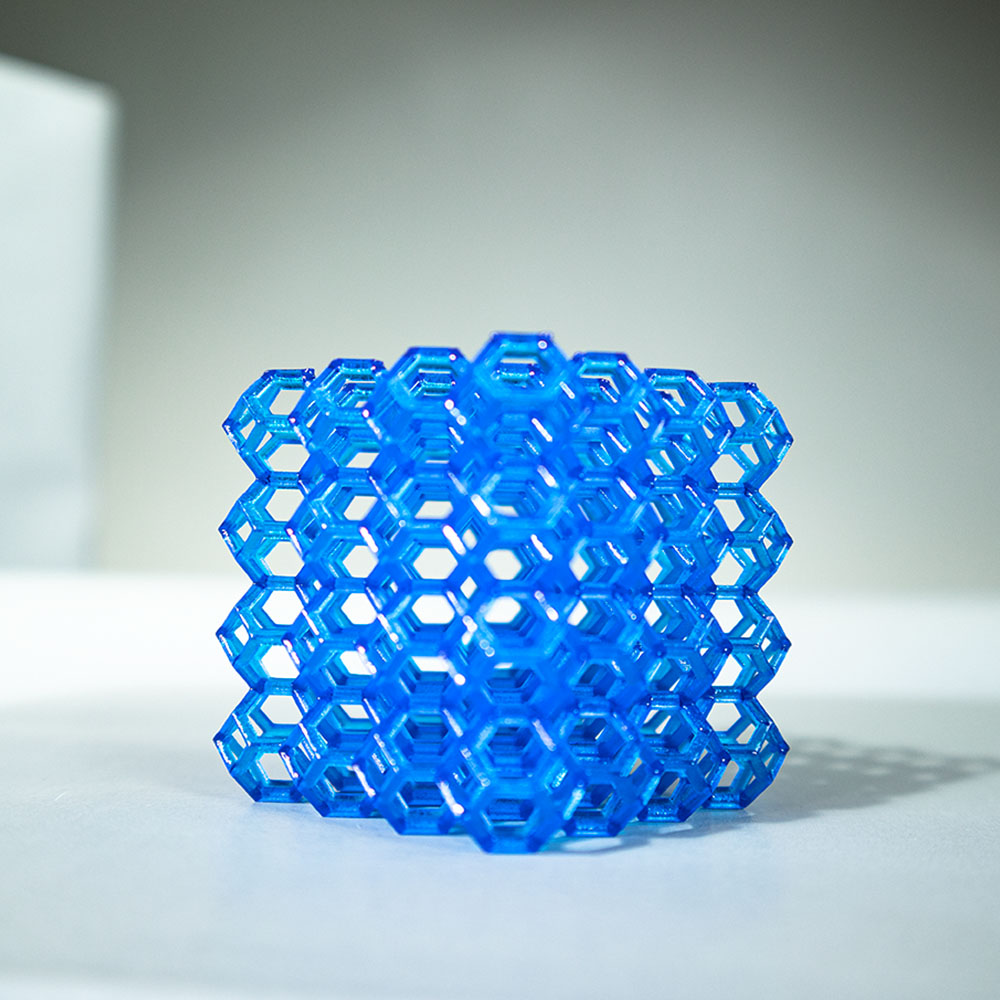

Rapid model resins are versatile as they can be printed between 5 and 100-micron layer heights. To achieve the best results, 3D models should always be sliced solid, if hollowing is required, ensure drain holes are included to remove any trapped resin.

Always angle the model on the build plate to avoid large flat areas that might cause printing problems. These include warping and deformation due to the adhesion to the FEP film. To assist with unsupported areas, ensure you use dense, well-positioned, solid supports.

This resin might print faster than other resins on the market, please adjust your settings accordingly. Use a calibration model from our website to dial in your printer with our resin.

Check our printer setting page to see if we have your printer listed to give you a good starting point.

MECHANICAL PROPERTIES

Method Code: ASTM D638-14

Product: Monocure 3D RAPID Model Resins (25μm)

Acceptance Code: Supply Findings

Specimen Type: Retangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

3DR-3582C, 3DR-3588GY, 3DR-3587BK, 3DR-3583W, 3DR-3585B, 3DR-3585GM

Cross-Sectional Area (mm2)

25.29

Max Force (kN)

1.64

Tensile Strength (MPa)

47

Elongation at Break

3.0

Young’s Modulus (GPa)

1.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

124

Max Flex Strain (mm/mm)

0.5

Shore Hardness (D)

75

Heat Deflection Temp

55°C @ 0.45MPa

FINISHING — WHAT'S THE BEST PRACTICE?

- For best results after printing, use ResinAway® for removing uncured resin from the part. Place part in a pre-wash bath filled with ResinAway® and use a soft brush to remove excess resin. Follow by placing the component into an ultrasonic cleaner with ResinAway® for 3-5mins to help remove the resin trapped in the finer detail.

- Ensure parts are dry by using compressed air or patting gently with a lint-free cloth before post-curing – Warning: leaving excess IPA or ResinAway® on parts might result in surface cracking.

- We recommend using a 405nm LED Ultraviolet light to post-cure the model. It is recommended to post-cure for a few minutes, then remove the excess ResinAway® by washing with fresh water. Then place it back in the curing chamber for at least 30 mins to improve the tensile strength of the resin.

- When exposing a part to external elements, apply paint to the surface to improve longevity. Alternatively, the components can be machined, sanded and polished to create a tough scratch resistant surface.

PHYSICAL PROPERTIES

SKUs

3DR-3582C, 3DR-3588GY, 3DR-3587BK, 3DR-3583W, 3DR-3585B, 3DR-3585GM

Colour(s)

Clear (100% trans) Grey (5% trans), Black (10% trans), White (0% trans), Blue (10% trans), Gun Metal (0% trans)

Viscosity

500 – 600cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

225nm to 420nm

Cure Speed

2-3 secs Mono Screen

Storage

Dark cool & dry place

Wash Up

RESINAWAY® or IPA