Rapid FLEX100 Resin

Endless bend-abilities with FLEX100 3D Printing Resin

Experience the creativity and versatility of 3D printing with Monocure3D’s FLEX100 resin, this unique resin was designed for creating flexible and bendable models or as an additive to enhance the flexibility of harder materials. Open your imagination and bring your ideas to life with this exceptional resin that excels in producing flexible models.

More Information below.

Description

Endless bend-abilities with FLEX100 Resin

Experience the creativity and versatility of 3D printing with Monocure3D’s FLEX100 resin, this unique resin was designed for creating flexible and bendable models or as an additive to enhance the flexibility of harder materials. Open your imagination and bring your ideas to life with this exceptional resin that excels in producing flexible models.

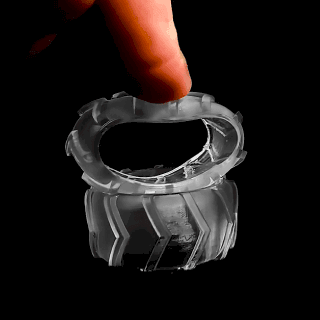

True Flexibility

FLEX100 stands out from the crowd with its extraordinary flexibility, enabling you to produce 3D models that can bend, twist, and conform to various shapes without compromising their integrity. This unique property makes FLEX100 the perfect choice for a wide range of applications, including:

-

Flexible prototypes: Create prototypes that mimic the feel and flexibility of real-world objects, allowing you to thoroughly test and refine your designs before committing to production.

-

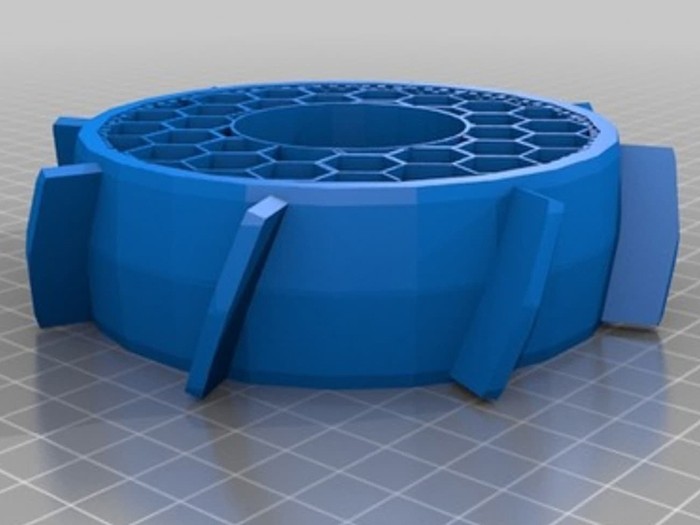

Bendable Models: Design and print parts that require flexibility, such as meshes, gaskets, and shock absorbers. FLEX100 ensures your creations can bend the way you need them to and then spring back to their original position.

-

Wearable accessories Prototypes: Create personalised and comfortable wearable accessories like bracelets, watch straps, and phone cases that flex comfortably with your movements.

-

Artistic creations: Perfect for those with artistic flair to create unique sculptures, figurines, and decorative objects with FLEX100’s remarkable flexibility.

Tailored Flexibility for Every Need

FLEX100 offers exceptional flexibility that can be customised to suit your specific requirements. The thinner the printed part, the more flexible it will be. Additionally, you can adjust the flexibility of your prints by mixing FLEX100 with our other resin systems. Adding a small amount of FLEX100 to our hard resins will enhance their durability and make them less brittle. Conversely, increasing the proportion of FLEX100 will result in a more flexible and pliable print.

Hassle-Free Mixing for Consistent Results

To ensure consistent and repeatable results, we recommend using a scale to weigh the resins when mixing. For a firm and durable resin, try a 25:75 mix, combining 25 grams of FLEX100 with 75 grams of hard resin. For a highly flexible print, aim for a 90:10 mix, using 90 grams of FLEX100 and 10 grams of hard resin.

Optimised Curing for Enhanced Flexibility

When mixing FLEX100 with our other resin systems, it’s crucial to extend the curing time to ensure complete curing of the flexible resin. This slower curing resin requires more UV exposure to fully harden. While the part may appear perfectly formed immediately after printing, insufficient curing can lead to cracks appearing later.

Tuning to Perfection: To achieve optimal results, we recommend visiting our printer settings page. Here, you’ll find comprehensive guidance to finely tune your printer for use with our resin, ensuring you get the best out of every print. If you need further assistance, please contact us through our support page or you can sign up to our Facebook Users Group and get instant help.

Proudly Australian Made & Supported: All our resins are expertly developed and manufactured in Australia, embodying our commitment to high-quality, constancy and trust. Our experienced chemists ensure each product meets rigorous standards. Plus, with our 100% MonoBACK guarantee, you have the confidence to buy, try, and return if not completely satisfied. Experience the Monocure3D difference with every purchase.

Technical Specifications

Resin Type: Soft Urethane Resin

Viscosity: Thin

Curing Wavelength: 405nm UV LED

Post-Cure Time: 30 minutes to 1 hour

Tensile Strength: Moderate

Shore A Hardness: 50

Odour: Moderate

Layer Height: 5-300 microns

Key Features

-

Fast curing time: FLEX100 resin cures in just 3-8 seconds at 405nm UV light, making it one of the fastest curing flexible resins on the market. This means you can print models and parts quickly and easily.

-

High accuracy: FLEX100 is known for its ability to print highly detailed models. This is due to its low viscosity and excellent flow properties, which allow it to capture fine details and produce smooth, even surfaces.

-

True Compatibility: This resin is easy to use and does not require any heat to use. It is compatible with a wide variety of 3D printers and can be printed with a variety of settings.

-

Long Lasting Flexibility: FLEX100 resin does not get harder over time like some of the other flexible resins on the market.

Applications

- Prototypes

- Hobby Models

- Art & Design

- Temporary models

- Educational Purposes

With its exceptional flexibility, ease of use, and versatility, FLEX100 is the ideal resin for both hobbyists and professionals looking to expand their 3D printing horizons. Discover the possibilities and bring your flexible creations to life with FLEX100 today.

Additional information

| Weight | N/A |

|---|---|

| Resin Size | 0.5L, 1L, 5L |

| Resin Colour | Clear |

Your Safety, Our Priority at Monocure3D

At Monocure3D, we place the utmost importance on the safety and well-being of our customers. Rest assured, every material we produce, proudly made in Australia, is designed to adhere to the highest safety standards in the industry. While we have formulated our resins to maximise safety, we strongly advise exercising caution during use. To ensure you have all the necessary information for safe handling, please follow the link below to download the Safety Data Sheet. These SDS’s are tailored according to the safety regulations of your specific country, ensuring you receive the most relevant and accurate safety guidelines.

Rapid prototyping | Flexible models | Flex Additive | High Impact models | Model Tyres | Sleeves & Joints | Grommets and Bumpers

Truly Flexible

A 3D Printing resin that is fully flexible when printed. Perfect for Prototype models that require these properties.

Ultimate Additive

FLEX100™ can mix with hard resins to give you different degrees of hardness and flexibility.

High Impact

Adding as little as 10% FLEX100™ into your hard resin can allow it to be dropped without breaking.

Low Viscosity

This formulation is at 30 cps (water is 0 cps). It can also help thin down resins in colder climates when a better flow is required.

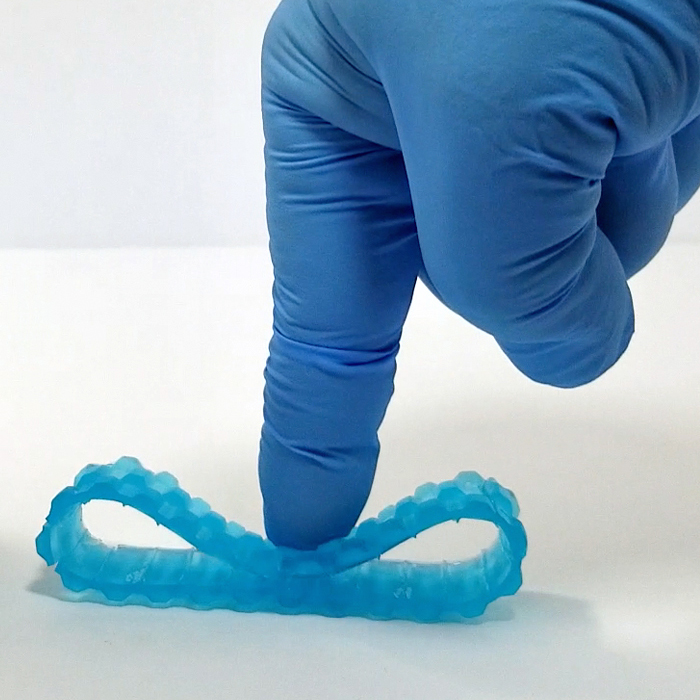

PRO Rubber-like Resin: The Future of Flexible 3D Printing

Monocure3D is excited to introduce the PRO Rubber-like resin, a groundbreaking development in 3D printing. This resin is a game-changer, offering a true rubber-like quality that takes flexible materials to the next level. Its unique composition allows it to closely mimic the elasticity of rubber, boasting the ability to stretch to over 166% of its original size and then return to its original shape after post-processing.

The resin comes with many features and benefits designed to meet the needs of users looking for robust, flexible, and durable materials. It exhibits impressive elongation and rebound rates, making it an ideal choice for creating functional prototypes and parts that require flexibility, stretchability, and durability. Moreover, it maintains a perfect balance of adhesion to the build plate, which facilitates easy removal of the print without compromising its integrity.

One of the standout qualities of the Rubber-like resin is its high-resolution output, which is achieved with minimal shrinkage or splitting. This ensures that every detail is captured, making it suitable for various applications. Additionally, the resin offers an authentic rubber-like feel, further expanding its potential uses across various industries.

An optimised post-cure process is recommended to enhance the tactile experience and usability of the printed objects. Following the post-processing guide provided will help achieve the best results.

FLEXIBLE PRINTING TIPS

Use thick, dense supports with good contact points when creating models using flexible material.

Increase the lift height to ensure the resin is released from the FEP film during printing.

If using as an additive, remember to use scales to weigh the resins so results can be repeated.

About FLEX100™ Resin

The FLEX100™ has an extremely high level of flexibility so you can 3D print compressible and bendable models.

The thinner the part, the more flexible it will be. FLEX100™ can be used on its own or by mixing with our other resin systems to produce varying degrees of flexibility and firmness. By adding a small amount of FLEX100™ to our other resins would create a less brittle and more durable part. By adding larger amounts, the more flexible it will become.

Remember to use scales to weigh the resins so results can be repeated. We recommend you make 100grams at a time to keep the ratios simple. For example, for a firm, durable resin try 25:75 mix – 25 grams of FLEX100™ to 75 grams of hard resin. For a very flexible version, you could try 90:10 mix 90 grams of FLEX100™ and 10 grams of hard resin.

IMPORTANT: When mixing FLEX100™ with our other resin systems, please ensure that you cure for a long enough time to fully cure the flexible resin. This is a slower curing resin and takes more UV exposure to fully cure. Although the part might look perfectly formed, if it hasn’t been cured for long enough, cracks may appear due to the resin being under cured.

All Monocure 3D resins have a very wide range of reactivity, UV wavelengths of 225nm to wavelengths of 420nm. By incorporating a blend of photo-initiators, monomers & sensitizers, almost any UV light source can be used to initiate the polymerisation process of our resins.

FINISHING — WHAT'S THE BEST PRACTICE?

For best results after printing, use ResinAway® for removing uncured resin from the part. Place part in a pre-wash bath filled with ResinAway® and use a soft brush to remove excess resin. Follow by placing the component into an ultrasonic cleaner with ResinAway® for 3-5mins to help remove the resin trapped in the finer detail.

Ensure parts are dry by using compressed air or patting gently with a lint-free cloth before post-curing – Warning: leaving excess IPA or ResinAway® on parts might result in surface cracking.

FLEX100™ requires post-curing to reach its optimal properties. We recommend using a 405nm LED Ultraviolet light to post-cure the model. It is recommended to post-cure for a few minutes, then remove the excess ResinAway by washing with fresh water. Then place it back in the curing chamber for at least 30 mins to improve the durability of the resin.

FLEX100 PROPERTIES

Product Code(s)

3DFR-3781C

Colour(s)

Clear Appearance

Viscosity

30-50 cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

225nm to 420nm

Cure Speed

3-5secs Mono MSLA

Storage

Dark Cool, dry place out of direct sunlight

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

RUBBER-LIKE PROPERTIES

Product Code(s)

M/RUB-4049BK

Colour(s)

Black (Solid at 3mm)

Viscosity

1400-1800 cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

225nm to 420nm

Cure Speed

2-4secs Mono MSLA

Storage

Dark Cool, dry place out of direct sunlight

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)