PRO Glow in the Dark Resin 1kg (70% OFF)

Honouring 10 Years with Next-Gen Resin Technology

We understand that 3D printing is a fast-moving industry, and to stay ahead of the competition, we’ve taken this product back to the lab. The result is a far superior resin base that’s easier to print, has lower odour, offers better mechanical properties, and is more affordable!

Use our Product Finder to explore alternatives by properties, finish, colour, or price. Need assistance? Contact us — we’re here to help!

In stock

Description

Honouring 10 Years with Next-Gen Resin Technology

We understand that 3D printing is a fast-moving industry, and to stay ahead of the competition, we’ve taken this product back to the lab. The result is a far superior resin base that’s easier to print, has lower odour, offers better mechanical properties, and is more affordable!

Use our Product Finder to explore alternatives by properties, finish, colour, or price. Need assistance? Contact us — we’re here to help!

Monocure3D PRO Glow in the Dark Resin (Discontinued Product)

Light up your printing adventure with Monocure3D’s PRO Glow in the Dark (GITD) resin. This is not just another 3D printing resin; it’s a spectacle of luminous wonder designed to bring a magical glow to your 3D creations. It is perfect for those who want to add an element of surprise and enchantment to their prints.

Key Features

Spectacular Glow Effect: Our PRO GITD resin is truly out of this world, offering an impressive glow that will surely amaze your family and friends. Watch your prints come to life with a captivating luminescence in the dark.

Long-Lasting Luminosity: M3D PRO Glow-in-dark Resin is the longest-glowing resin on the market. It can emit light for up to 12 hours after being charged with normal daylight, ensuring your creations stay illuminated throughout the night.

No Settling on Long Prints: Specially formulated to maintain consistency, our PRO GITD resin does not settle, even on long prints. This means you get uniform glowing effects throughout your entire model.

Versatile Printing Capabilities: Ideal for a wide range of applications, this resin is suitable for printing with layer heights from 10 to 100 microns, accommodating various design preferences and project requirements.

Affordably Priced: Now available at a new, more affordable price, our PRO GITD resin is accessible for everyone looking to add a unique and glowing touch to their 3D prints.

LCD Screen Friendly: Like all our resins, the PRO GITD resin is formulated to be gentle on LCD screens, supporting sustainable and cost-effective printing practices.

Proudly Australian Made & Guaranteed: All our resins are expertly developed and manufactured in Australia, embodying our commitment to high quality, constancy and trust. Our experienced chemists ensure each product meets rigorous standards. Plus, with our MonoBACK guarantee, you have the confidence to buy, try, and return if you are not completely satisfied. Experience the Monocure3D difference with every purchase.

Monocure3D’s Glow in the Dark resin is more than just a novelty; it’s a testament to innovation and creativity in 3D printing. Ideal for artistic projects, night-time accessories, or any print that needs an extra touch of wonder, this resin ensures that every creation doesn’t just stand out in the light and glows impressively in the dark.

Illuminate your 3D printing journey with Monocure 3D Glow in the Dark resin – where every print becomes a wonder and delight.

Industrial | Engineering | Medical | Prototypes | Housings | Robotic Parts | Display | Large Format Models | Crystal Clear Models

Now anyone can 3D Print like a PRO

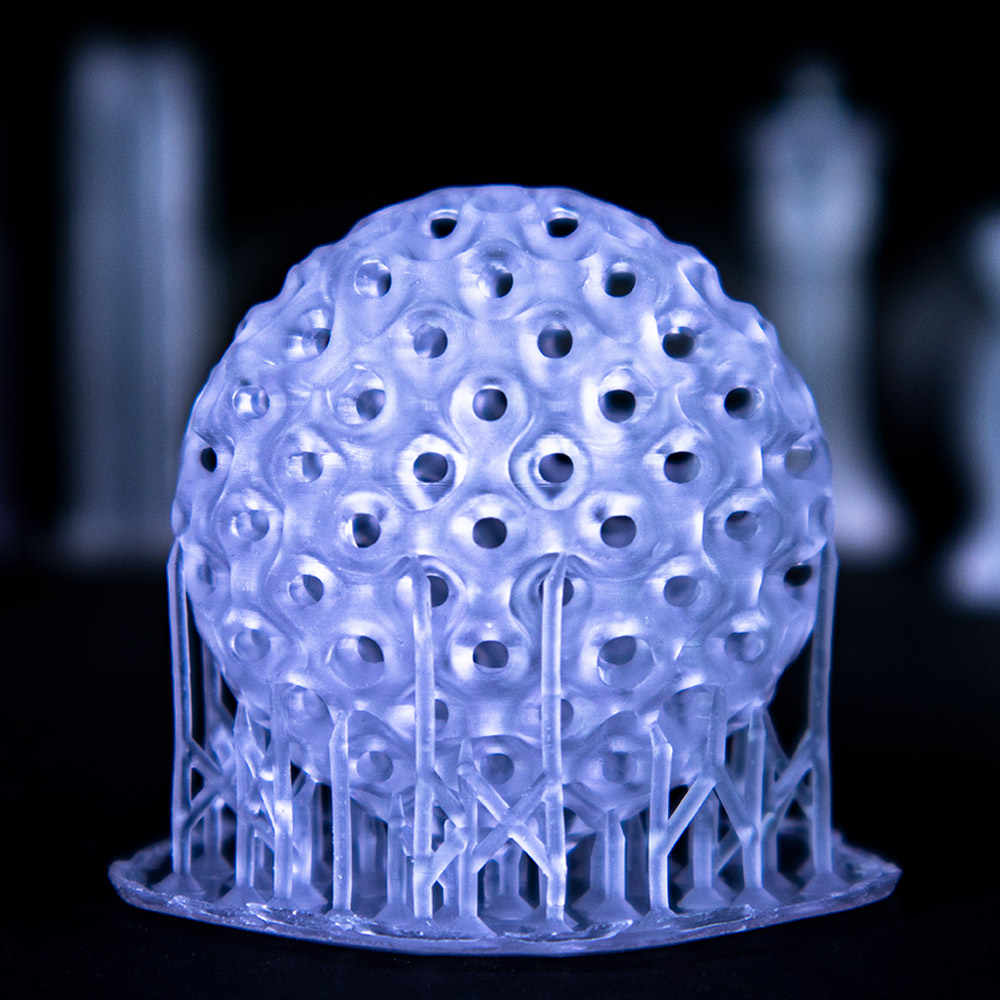

PRO CRYSTAL CLEAR

One of our original PRO resins, a truly clear 3D Printing resin! Formulated using our advanced urethane base, this unique product allows you to print parts with outstanding clarity, strength and durability.

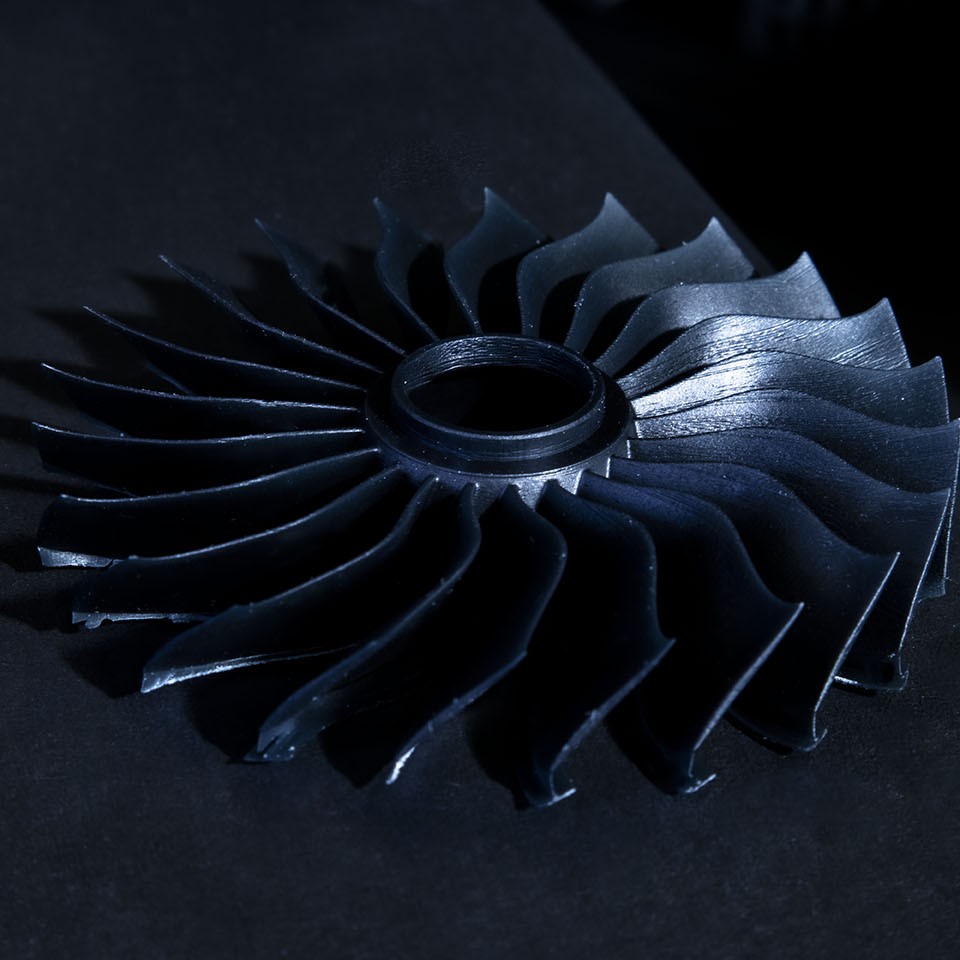

PRO DEEP BLACK

You asked for it, so our chemists delivered it. The first real dense black 3D Printing resin on the market. A heavily pigmented resin that lives up to its name without compromising the print details.

PRO RUBBER-LIKE

Finally, a true rubber-like 3D Printing Resin, taking flexible materials to the next level! This resin has a unique composition closely resembles rubber in elasticity after post-processing with the ability to stretch to over 166% and return to its original shape.

PRO GLOW IN THE DARK (GITD)

Our famous Glow in the Dark Resin took 12 months to develop! It was formulated to be the longest glowing 3D printing resin on the market (guaranteed to glow all night).

About our PRO Resin Range

Our PRO resins were specifically developed for those wanting professional results. All our Enduro resin products in the PRO range are built using our advanced in-house developed polyurethane base material, ensuring tough, long-lasting models with no shrinkage or warping, plus more tolerance to heat & UV exposure. Our range of unique, reliable PRO resins has been formulated to help you work faster and print professional-looking parts every time.

You don’t need to look further than our PRO range when you need products with superior quality and batch-to-batch consistency.

PRO ENDURO MECHANICAL PROPERTIES

Method Code: ASTM D638-14

Product: Monocure 3D PRO Resins (25μm)

Acceptance Code: Supply Findings

Specimen Type: Retangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

3DT-3926DBK, PGM-3931G, 3DT-3884LGY, 3DT-3900CC

Cross-Sectional Area (mm2)

26.47

Max Force (kN)

1.64

Tensile Strength (MPa)

62

Elongation at Break

4

Young’s Modulus (GPa)

0.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

348

Shore Hardness (D)

92

Heat Deflection Temp

71°C @ 0.45MPa

PRO RESIN PRINTING TIPS

Always shake resin well before printing. It’s recommended to wait for the surface bubbles to pop before starting your print. PROTIP: A lighter or heat gun can speed up this process.

The new large format printers can 3D Print massive models but have tend to have low volume vats. Ensure you have enough resin to complete the print job, and remember to top up the resin vat if necessary.

When stored correctly, Monocure 3D resins can last up to 36 months. Remember to keep your resin in its original bottle, in a dark, cool place away from direct sunlight. Do not allow the materials to freeze.

For the best result with Crystal Clear, always post-cure using 405nm UV light for a short time only. Polishing or using a clear gloss acrylic spray paint, will give you see-through results.

PROFESSIONAL ADVICE WHEN YOU NEED IT

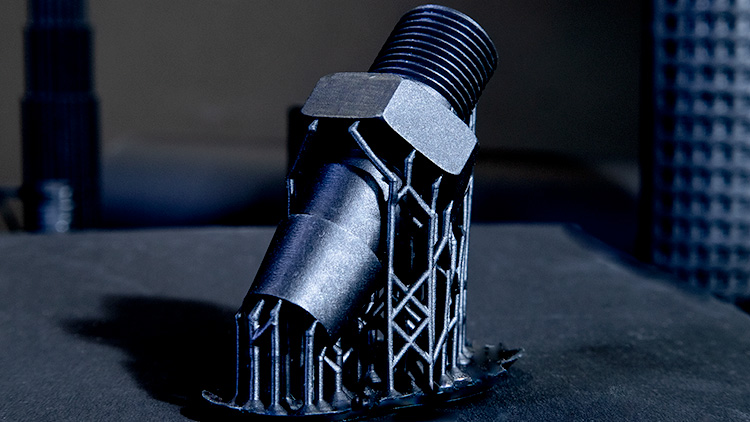

All Monocure 3D PRO resins are versatile and can be printed between 10 and 100-micron layer heights. To achieve the best results, 3D models should always be designed solid. If hollowing is required, ensure drain holes are included to remove any trapped resin.

Check our printer setting page to see if we have your printer listed to give you a good starting point. (Not all slicers have this setting, check with your software provider). Use a calibration model to dial in your printer with our resin.

We are here to help! Please contact us if you need assistance. Local manufacturing means local support. When you buy from us, you are not just buying a product from a faceless company. We have years of 3D printing and technical support experience.

PRO™ PHYSICAL PROPERTIES

SKUs

3DT-3926DBK, PGM-3931G, 3DT-3884LGY, 3DT-3900CC

Viscosity

200-300cps @ 25°C(Brookfield RVT)

Odour

Negligible Characteristic

Active Solids

100%

Shelf Life

36 months

UV Cure

225nm to 420nm

Particle Size

< 10um

Cure Speed

Fast with UV LED

Storage

Dark Cool & Dry Place

Wash Up

RESINAWAY® or IPA

3 STEPS TO A PERFECT FINISH

For best results after printing, use ResinAway® to remove uncured resin from the part. Place part in a pre-wash bath filled with ResinAway® and use a soft brush to remove excess resin. Follow by placing the component into an ultrasonic cleaner with ResinAway® for 3-5mins to help remove the resin trapped in the finer detail.

- Ensure parts are dry by using compressed air or patting gently with a lint-free cloth before post-curing – Warning: leaving excess IPA or ResinAway® on parts might result in surface cracking.

- PRO™ resin requires post-curing to reach its optimal mechanical properties. We recommend using a 405nm LED Ultraviolet light to post-cure the model. It is recommended to post-cure for a few minutes, then remove the excess ResinAway® by washing with fresh water. Then place it back in the curing chamber for at least 30 mins to improve the tensile strength of the resin.

- When exposing a part to external elements, apply paint to the surface to improve longevity. Alternatively, the components can be machined, sanded and polished to create a tough, scratch-resistant surface.