Description

Description

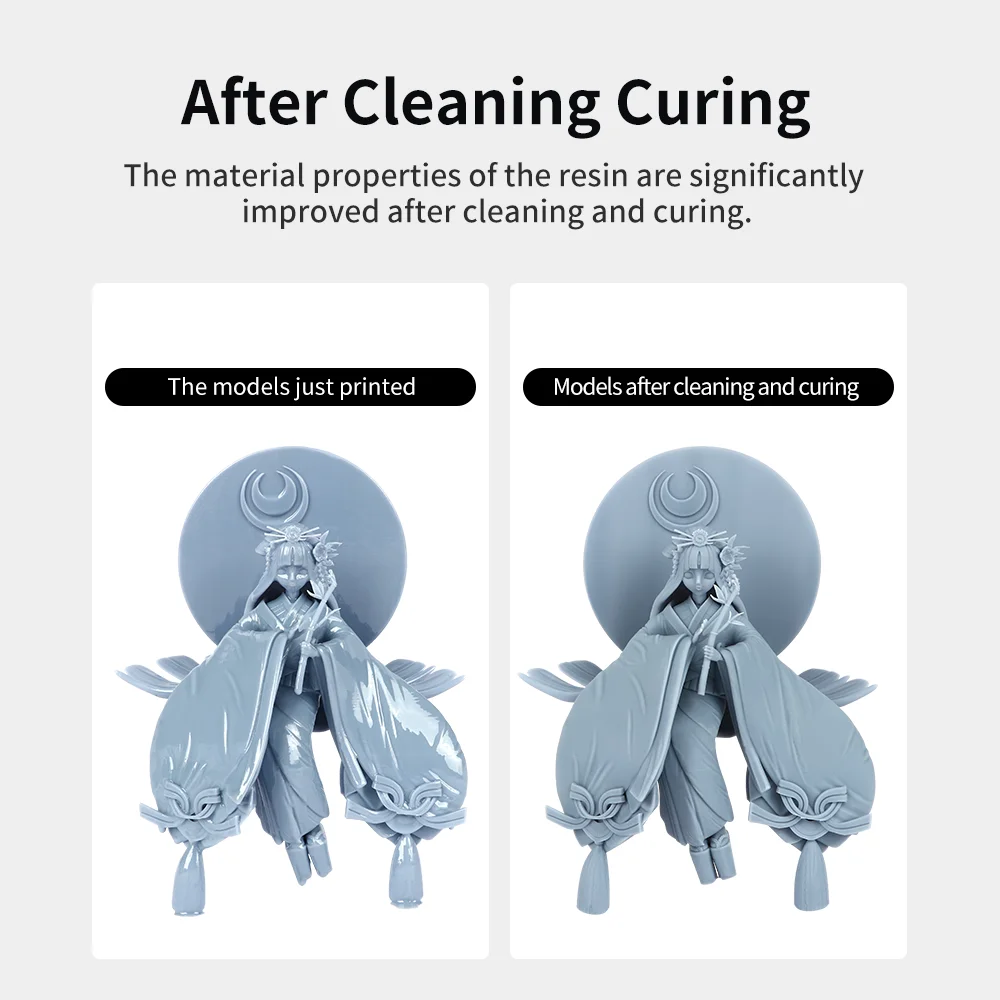

The Anycubic Wash and Cure 3 is an all-in-one solution designed to simplify post-processing for resin 3D prints. With a larger washing volume and upgraded UV curing system, this machine ensures your prints are thoroughly cleaned and evenly cured for maximum strength and detail. By combining washing and curing in one device, it saves time, reduces mess, and delivers consistent results.

This wash and cure station is ideal for resin 3D printing enthusiasts, hobbyists, and professionals seeking reliable performance. The Anycubic Wash and Cure 3 offers 360° curing coverage with an upgraded L-shaped light bar and turntable system, enabling easy creation of smooth surfaces and durable models. Washing mode offers adjustable cleaning options for both open prints and prints still on the build plate.

Whether you are working on prototypes, miniatures, dental models, or engineering parts, the Anycubic Wash and Cure 3 is an essential accessory for high-quality resin printing workflows.

Key Features

- Combines washing and curing in one compact device

- Upgraded to a larger washing container for bigger prints

- Delivers 360° curing with L-shaped light bar and rotating platform

- Supports cleaning prints directly on the build plate or removing them

- Adjustable washing and curing times for customised results

- Safe, enclosed design reduces resin exposure and odours

Disclaimer: This Anycubic Wash and Cure 3 is shipped directly from our overseas warehouse and will arrive separately from any locally made products. Once shipped, you will receive tracking information. These items are not stocked in Australia.

Please note: electrical equipment may not include the correct plug for your country unless specified.

Anycubic Wash & Cure 3

Larger Size for Upgraded Capacity

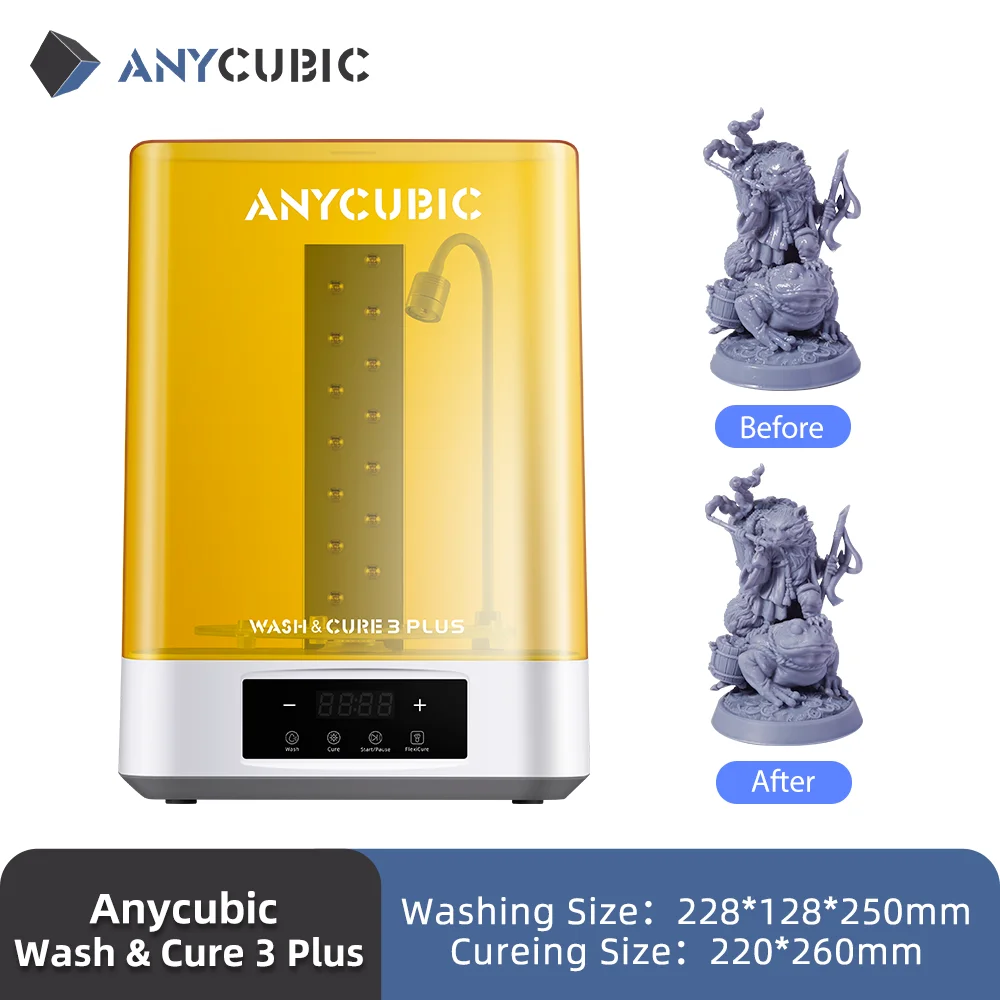

Compared to Anycubic Wash & Cure 2.0, the Anycubic Wash& Cure 3 has an impressive 100% increase in cleaning basket capacity, now at 3 litres. The total volume of the cleaning bucket has been expanded to 4 litres. This makes it perfectly tailored for LCD (light-curing) 3D printers with a size of 7.3 inches or less.

The curing size has increased by 15%, up to 160*180 millimeters, to accommodate larger and more models for single post-processing session.

Localised Strengthening, Uniform Curing

The “Innovative Flexicure Gooseneck Light Design” increases the energy value by 30,000uW/cm² within a 1-3 cm irradiation range, significantly strengthening the curing effect on subtle areas such as the top of models and the hem of garments.

*Data sourced from Anycubic Laboratory

By adopting a brand-new arrangement of light beads and lens light source, Anycubic Wash & Cure 3.0’s curing uniformity has been enhanced by 20%* compared to its predecessor 2.0. This results in a more thorough curing of the entire model.

Dual-layer Design, IPA Saving

The double-layered PP material cleaning basket is designed to support simultaneous cleaning with the platform. It features two adjustable heights at 100mm and 165mm, providing flexibility to accommodate printing platforms ranging from 5.9 inches to 7.3 inches. This design maximises the efficiency of IPA usage.

Cleaning basket made of PP material (rust-resistant) VS the previous generation’s metal material (prone to rust)

Simple Operation, Quiet and Efficient

Cleaning and curing dual modes are easily selected with a single click. The Enhanced Gooseneck light curing mode can be toggled on and off with a single click, offering infinite rotary knob control adjustable from 1 to 30 minutes at will.

By implementing a more sealed structural design and optimising software, noise interference during cleaning and curing is minimised, resulting in a quieter and more comfortable working environment.

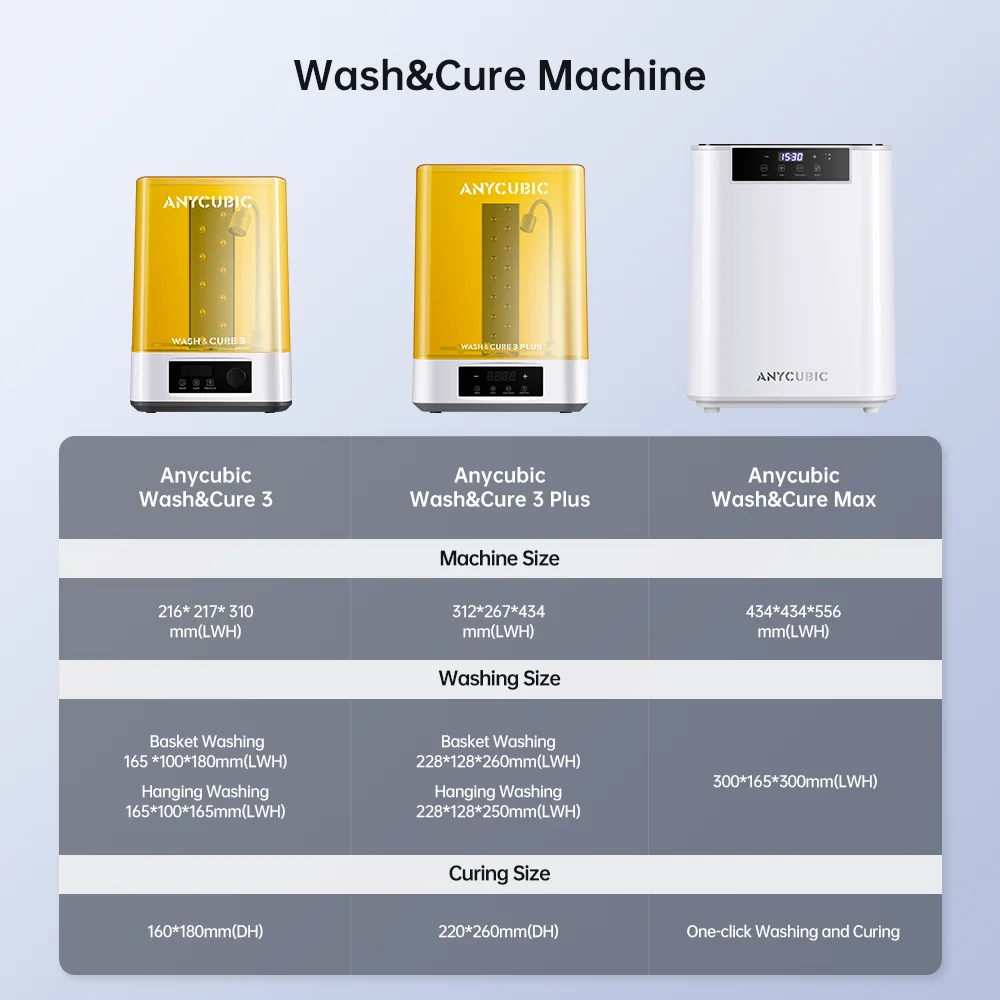

Machine Model Comparison

Anycubic Wash & Cure 3 Max

Big Dimension, 1-click Operation

15.1L Ultra-large Capacity / Thorough Cleaning/ Wash & Cure All-in-1/ Conserving IPA

Extra-large, Ultra-capable

The 15.1L Anycubic Wash & Cure 3 Max has a maximum wash capacity of 305*165*300mm; a 98.55% capacity increase over the Anycubic Wash & Cure 3 Plus. Compatible with LCD 3D printers with a build volume of 13.6-inch or lower.

Fully Automated All-in-1 Cleaning Station

No more getting your hands dirty during washing and curing; just one click is all it takes for a fully automated process from start to finish.

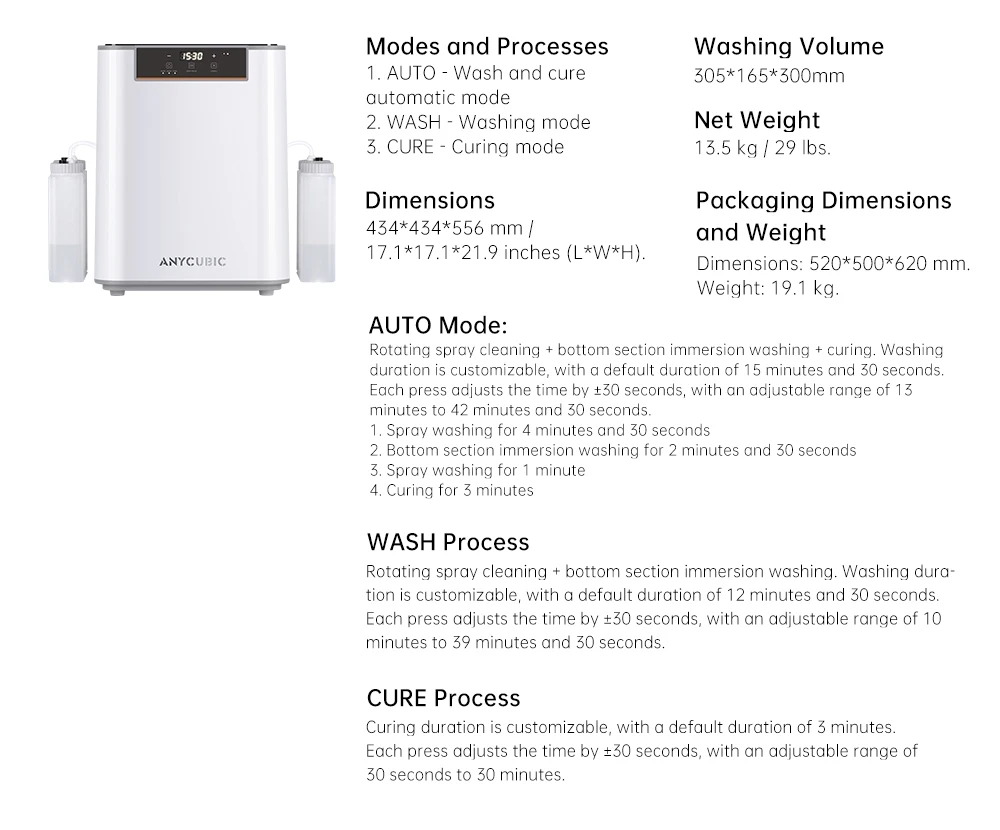

Customizable Wash & Cure Process

*Automatic mode:Spray+Immersion+Cur ing with customizable washing duration.

*Washing mode :Customizable washing duration.

*Curing mode :Customizable curing duration.

360° Spray Cleaning

Spray cleaning/Bottom section cleaning/Improved basket load capacity

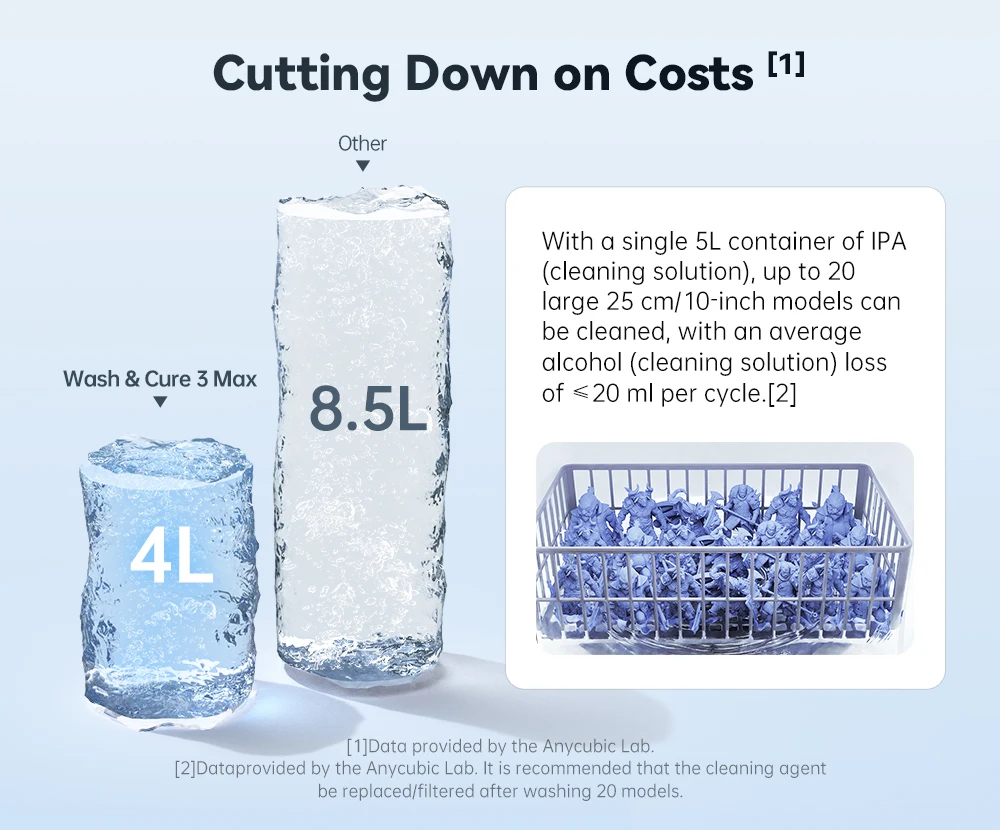

Cutting Down on Costs

The dual cleaning mode (spray +immersion) significantly reduces IPA consumption. Cleaning o large 25 cm/10-inch model requires only about 4L of IPA (cleaning solution), achieving nearly 50% savings compared to the 8.5 liters used in traditional immersion wash & cure.

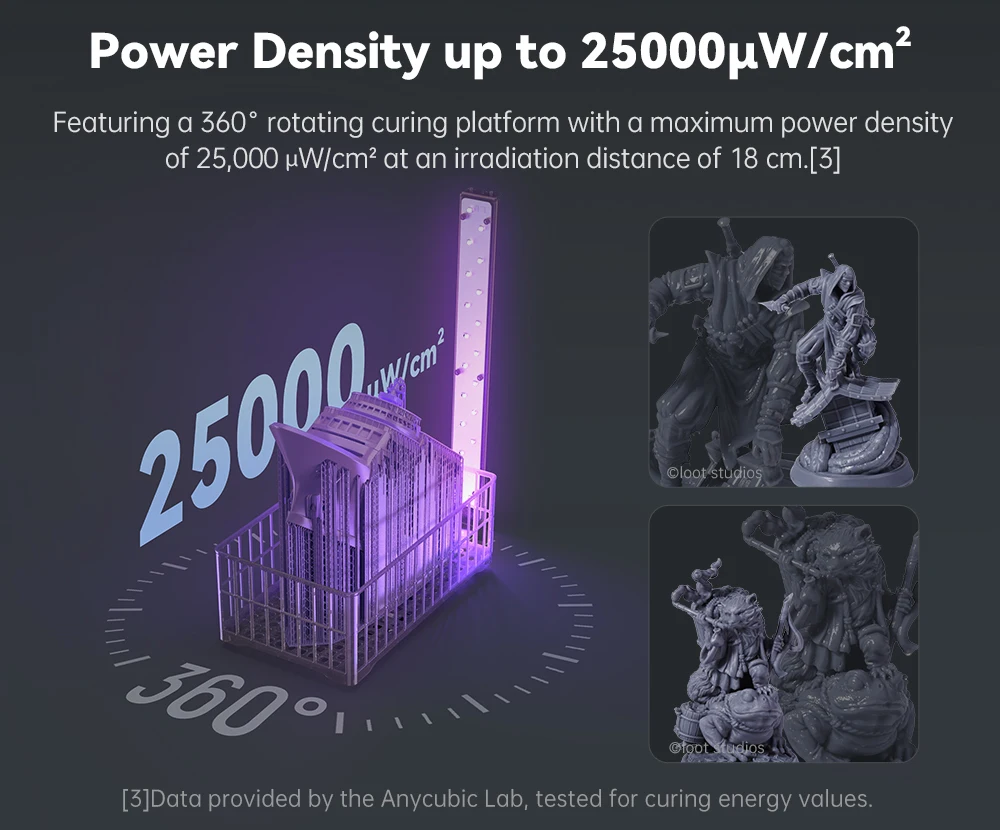

Power Density up to 25000μW/cm2

Featuring a 360° rotating curing platform with a maximum power density of 25,000 μW/cm? at an irradiation distance of 18 cm

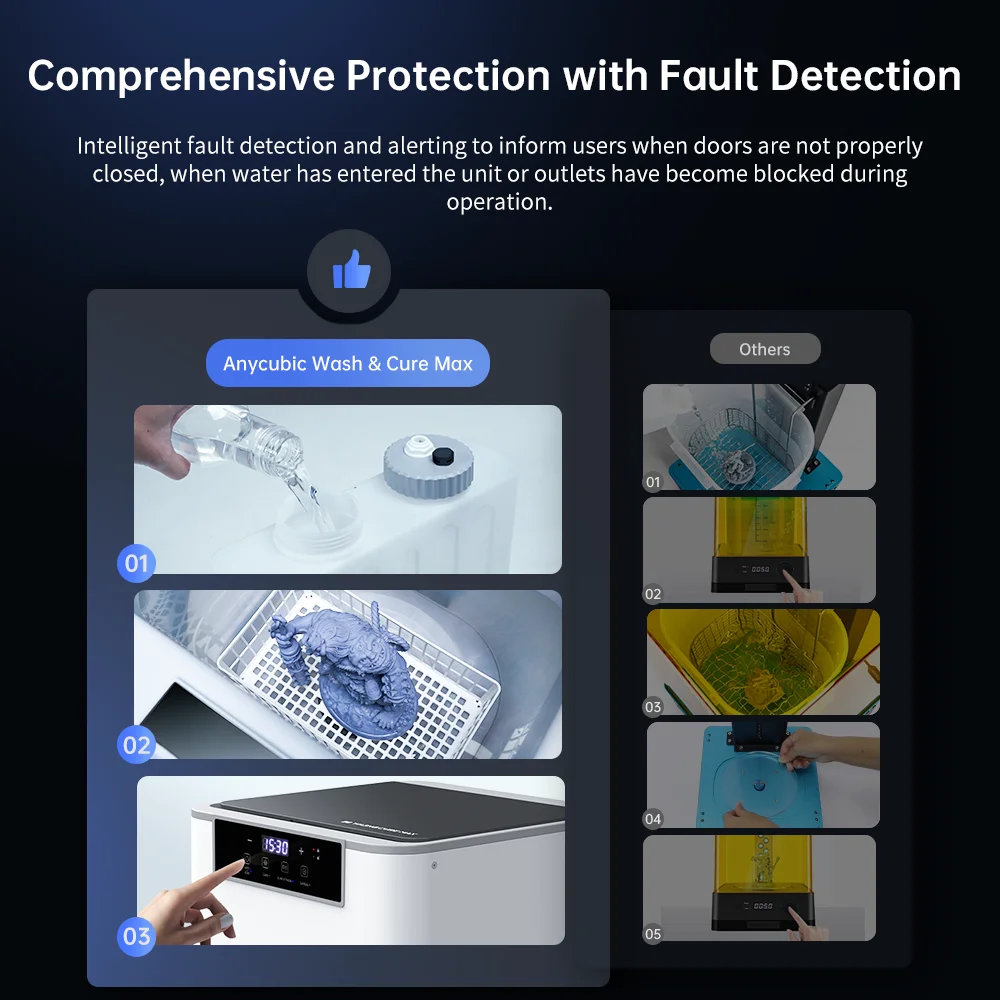

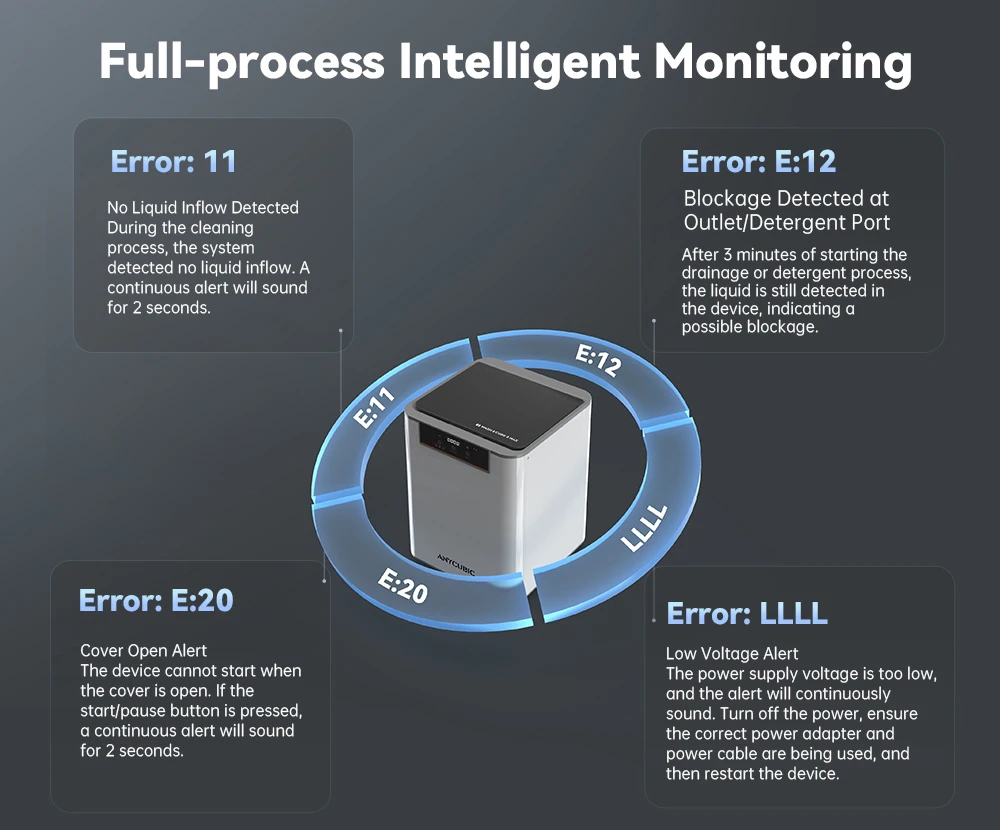

Full-process Intelligent Monitoring

The device cannot start when the cover is open. If the start/pause button is pressed, a continuous alert will sound for 2 seconds.

Aesthetic & All-in-one

Transparency and simplicity. Flip-open lid and minimalistic control panel.

Product Parameters

What’s in the Box