PLATEBOND™ Adhesion Promoter for Resin 3D Printing

PLATEBOND™ is a UV-cured build plate adhesion promoter developed to ensure reliable first-layer adhesion for resin 3D printing. Whether you’re printing large models, working with an older build plate, or experiencing first-layer issues, PLATEBOND™ helps reduce warping, lifting, and separation. It’s compatible with all Monocure3D resins and other UV-cured photopolymer systems, and works across MSLA, LCD, and DLP printers. Apply a thin, even coat to a clean build plate before printing. Once cured during the first exposure, it forms a strong, consistent bond between the model and the plate, so your prints stay exactly where they should.

In stock

Description

Ensure your first layer sticks every time with Monocure3D PLATEBOND™, a specially formulated adhesion promoter designed to improve build plate grip for resin 3D prints.

Developed for use with any UV-cured resin system, including Monocure3D’s full range, PLATEBOND™ provides a reliable interface between the first printed layer and the build surface. It’s ideal for challenging prints, large flat models, or printers with older or worn build plates.

Key Features:

-

UV Cured – Designed to work with all photopolymer resins cured by UV light

-

Strong Initial Adhesion – Helps prevent warping, curling, or first-layer separation

-

Universal Compatibility – Suitable for MSLA, LCD, and DLP 3D printers

-

Simple Application – Apply a thin layer directly to a clean build plate

-

Multi-Resin Support – Effective with Monocure3D and other third-party resin systems

When to Use:

-

Printing large surface-area models

-

Working with older or worn build plates

-

Printing in colder environments

-

When experiencing first-layer failures or warping

For best results, apply a thin, even coat to a clean build plate before printing. Once cured during the initial exposure phase, PLATEBOND™ forms a secure base layer, ensuring consistent print success from the ground up.

Additional information

| Weight | 0.2 kg |

|---|---|

| Dimensions | 3 × 3 × 3 cm |

APPLICATION & TIPS

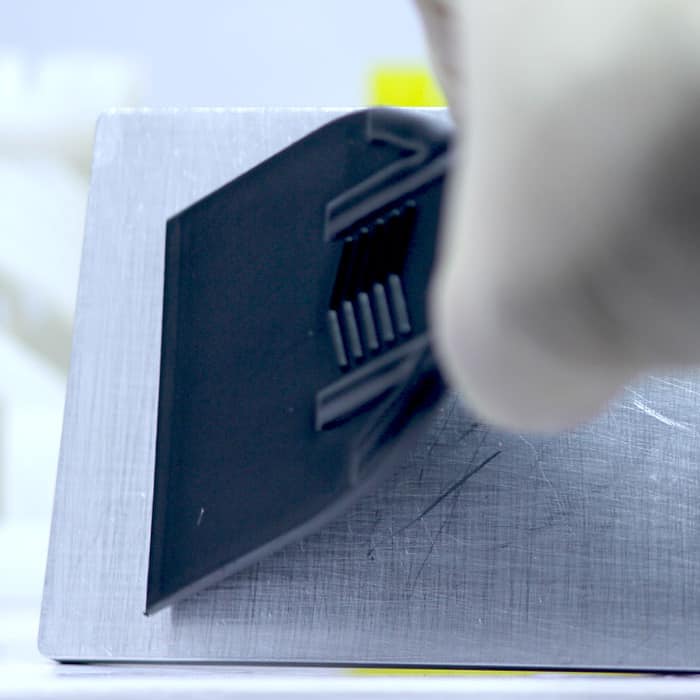

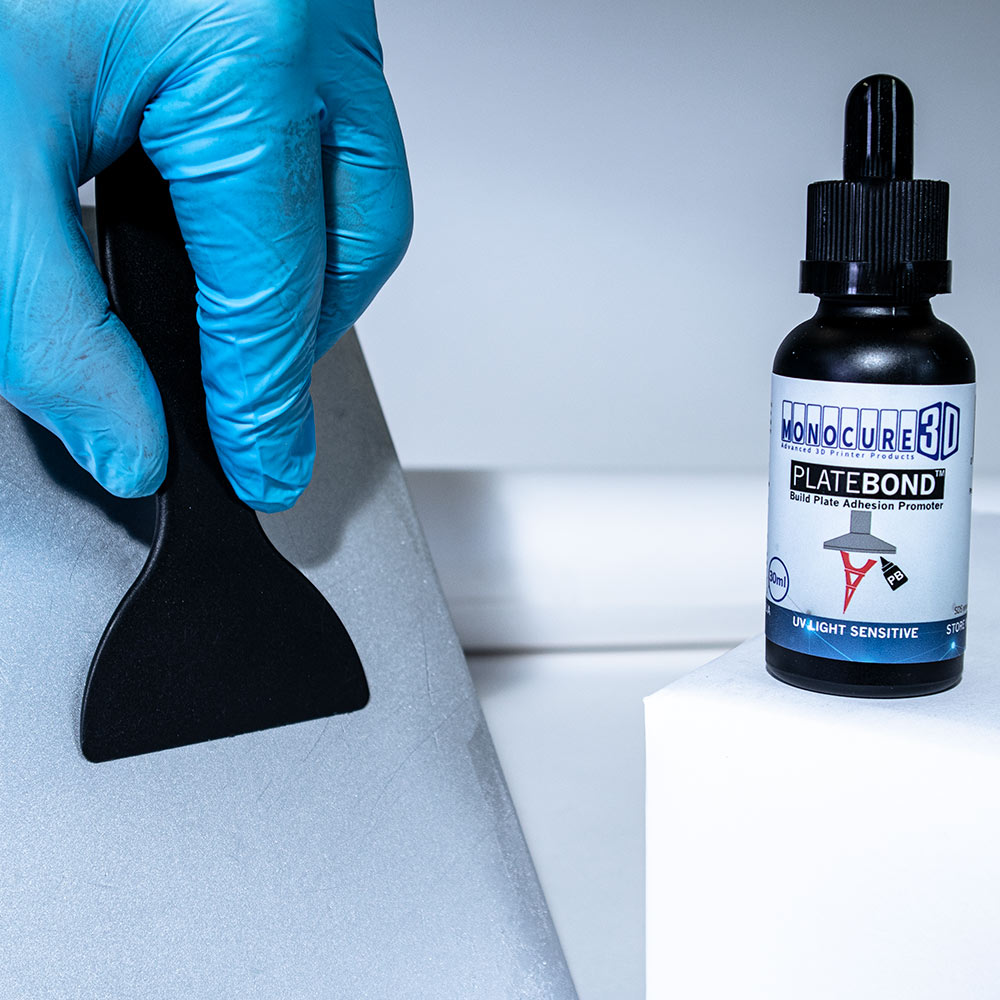

Ensure the build plate is clean and dry. Apply a few drops onto your 3D printer's build plate using the dripper provided.

Using a metal scraper or gloved finger, smear the PLATEBOND™ liquid UV adhesive across the entire print area.

Allow the 3D printer to cure the PLATEBOND™ with the first few base layers. (It does not need to be cured before printing).

If the model is difficult to remove after printing, run hot water over the back of the build plate to help release the 3D printed part(s).

HOW TO HANDLE PLATEBOND

Storage

Store PLATEBOND™ in a dry, cool place, away from direct sunlight.

Warning

This is a UV sensitive product. Please keep the lid on when not in use.

PPE

Always wear recommended safety PPE when handling this product.

Info

Refer to Physical Properties & SDS (Saftey Data Sheet) for more information.

PHYSICAL PROPERTIES

Product Code(s)

3DPB-3793

Colour(s)

Transparent

Viscosity

1000cps

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

225nm to 420nm

Cure Speed

Very fast with UV Lasers & LEDs

Storage

Dark Cool, dry place out of direct sunlight.

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

HOW TO USE PLATEBOND

- Apply a few drops onto your 3D printer’s build plate using the dripper provided.

- Smear the PLATEBOND™ liquid UV adhesive across the entire print area.

- Start your print as normal to allow the 3D printer to activate the PLATEBOND™ with the first few resin base layers.

- If the model is difficult to remove after printing, run hot water over the back of the build plate to help release the 3D printed part(s).