XXL ACF Film

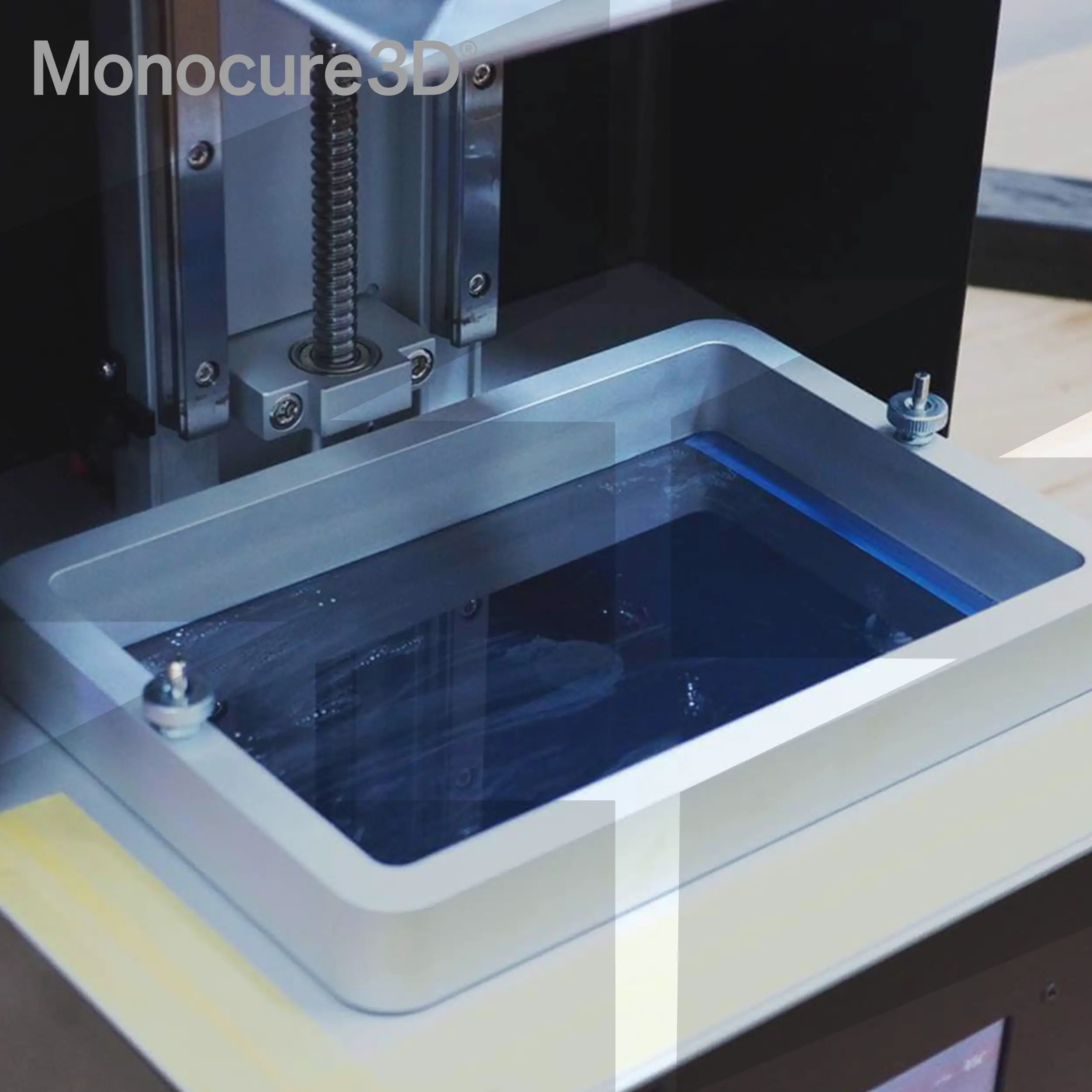

ACF Advanced Copolymer Film for MSLA 3D Printers – 1 Sheet Pack

Ideal for larger-format printers where easy release and low peeling force are paramount, ACF excels in producing high-quality, detailed models across various industries, including engineering, dental, and manufacturing. Whether you are creating intricate designs or large-scale prototypes, ACF provides the reliability and quality assurance needed to achieve superior printing results.

Because ACF is softer than traditional films, it is more susceptible to tearing or puncturing if not used correctly. It is essential to ensure that the resin, printer, and film are all correctly calibrated before starting production runs.

Use our FEP Size Finder to match the correct-sized film to your 3D printer. Need help replacing your ACF Fep Film? Check out our How to Change Your FEP guide for step-by-step instructions.

📥 Download Technical Data Sheet

In stock

Description

ACF Advanced Release Film for MSLA 3D Printers – 1 Sheet Pack

Premium Separation Film for High-Performance Resin Printing

Ideal for larger-format printers where easy release and low peel force are paramount, ACF Advanced Release Film excels at producing high-quality, detailed models across industries including engineering, dental, and manufacturing. Whether you’re creating intricate designs or large-scale prototypes, ACF provides the reliability and print quality needed to achieve consistent results.

What is ACF?

The ACF Advanced Release Film is a next-generation elastic separation film engineered for bottom-up MSLA 3D printers. Made from a proprietary blend of FEP (Fluorinated Ethylene Propylene) and PTFE (Polytetrafluoroethylene), ACF provides exceptional release characteristics and superior durability, while maintaining excellent optical clarity to improve cure consistency.

Unlike standard separation films such as FEP or PFA, ACF is softer and more flexible, which means it absorbs some of the mechanical forces during the peel process. This can lead to better print outcomes, particularly when printing large, flat objects or intricate parts where adhesion to the film can otherwise cause warping or delamination.

Key Features & Benefits

- Ultra-Low Peeling Force – Reduces stress on the model, enhancing success rates

- Enhanced Optical Clarity – Improves UV light penetration for more accurate curing

- Flexible & Durable – Engineered for large-format and high-detail prints

- Ideal for Flat Models – Reduces print failure risks on large surface areas

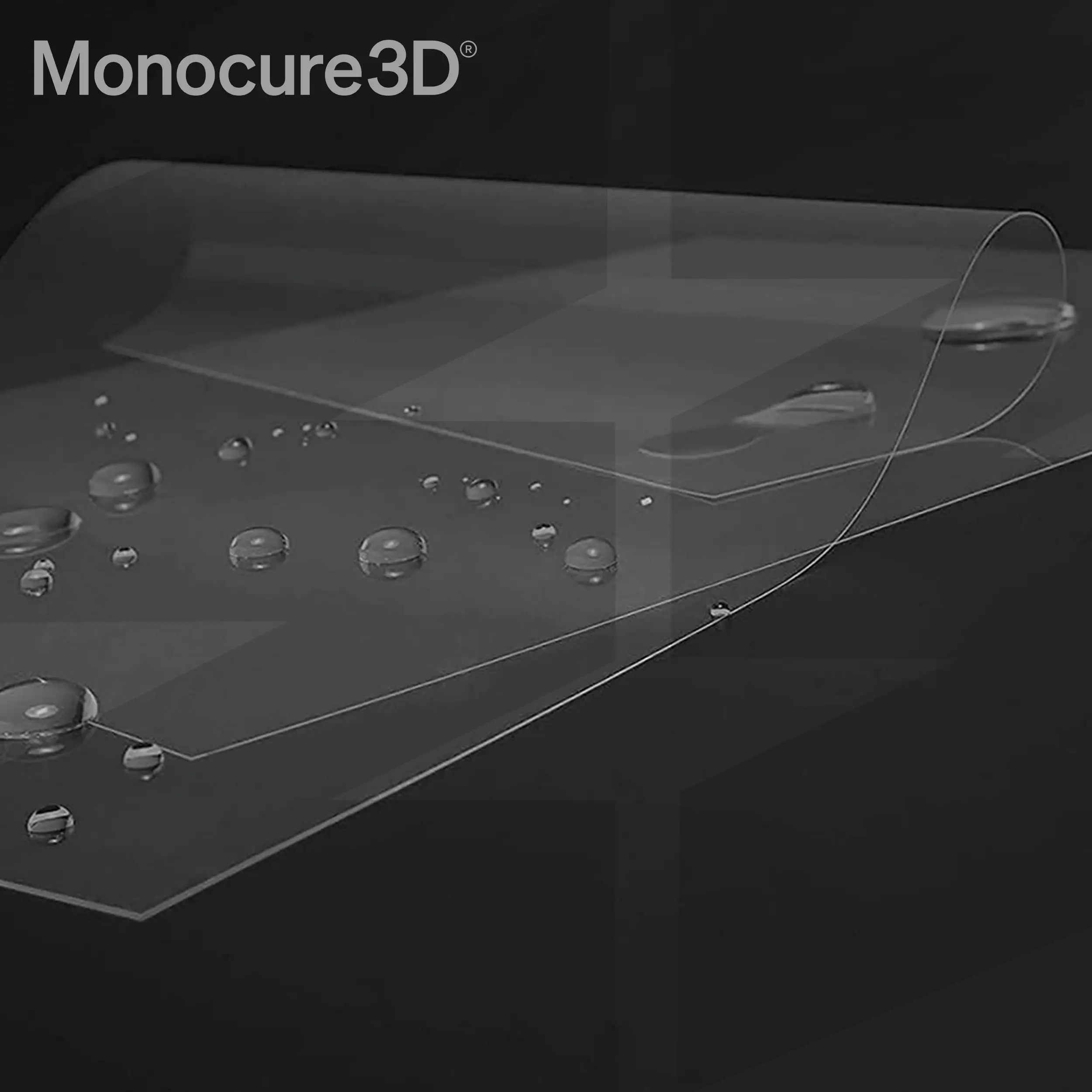

- High Chemical Resistance – Compatible with a wide range of aggressive resins

Use With Care: Important User Considerations

Because ACF is softer than traditional films, it is more susceptible to tearing or puncturing if not used correctly. It is essential to ensure the resin, printer, and film are properly calibrated before starting production runs.

Follow These Steps to Maximise Film Life and Print Success:

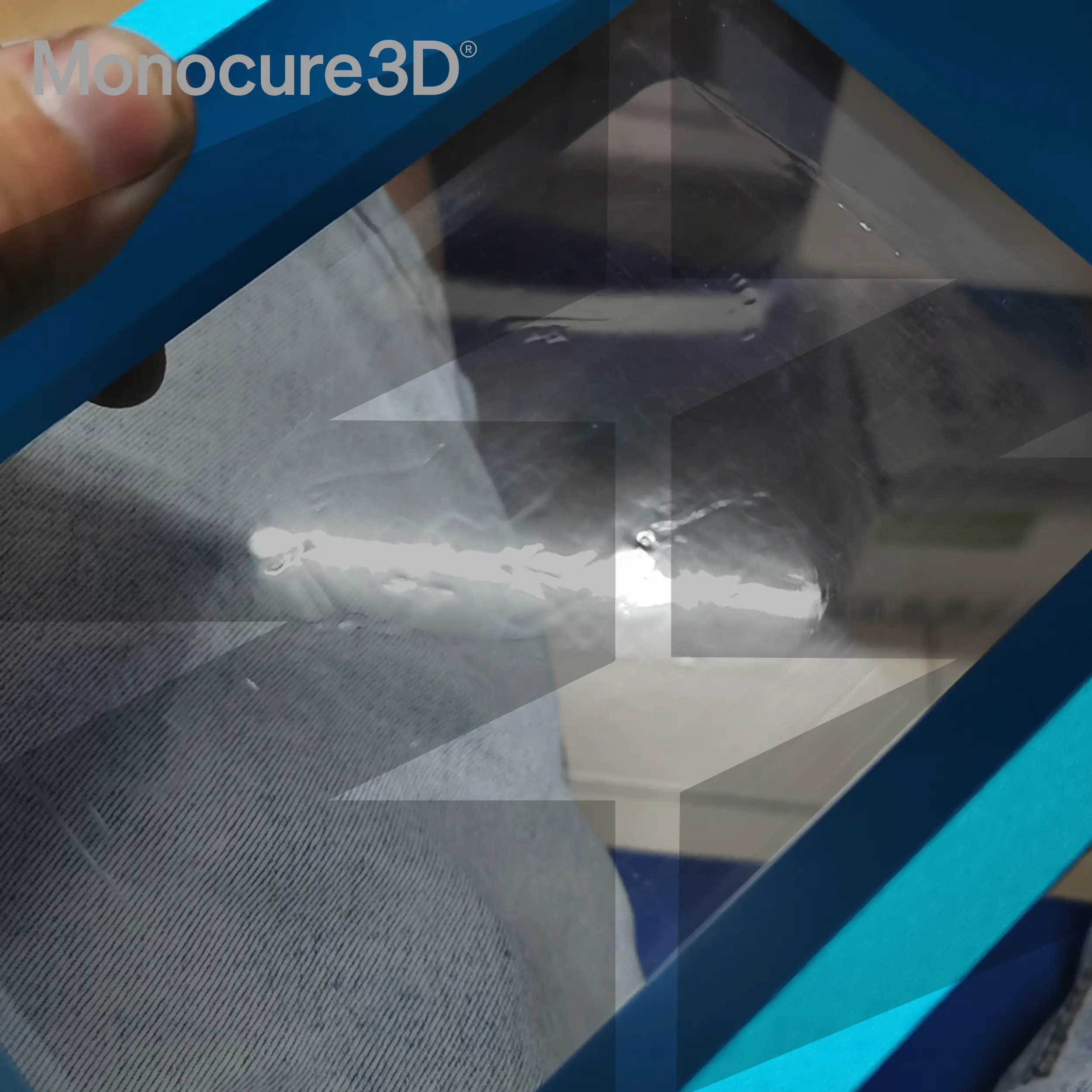

- Important: Ensure the glossy side of the film faces the resin vat, and the matte side faces the LCD screen.

- Perform a calibration print (such as our MonoMatrix model) whenever changing resin, printer, or film type

- Adjust exposure settings based on the resin used and the film’s characteristics — overcuring or excessive adhesion can cause damage.

- Inspect the film surface regularly for signs of wear, deep scratches, or deformation.

- Avoid overloading the build plate with large or multiple models until settings have been confirmed.

- Use Monocure3D resin and recommended settings as a baseline for safe and consistent performance.

Disclaimer: Damage Due to Incorrect Use

Monocure3D will not be held responsible for damage to printers, vats, LCDs, or any associated hardware due to:

- Tearing or puncturing of the ACF film during use

- Improper installation or maintenance, i.e., installing incorrectly

- Use of incompatible resins, pigments, or additives

- Failure to calibrate exposure times or dial in print settings

- Environmental factors such as light exposure or incorrect storage

- Resin leaks due to poor installation or a lack of user experience

UV resin is a light-sensitive material and must be handled with care. MSLA printing requires experience and a thorough understanding of printer setup, exposure calibration, and environmental control (including temperature and ambient light safety). Print rooms should be light-safe, and all films, resins, and equipment should be used strictly as recommended.

Perfect for Large Format and High-Precision Printing

ACF is particularly beneficial for large-format MSLA printers, where low peeling force is critical for reducing print stress and preventing failure. This makes it the ideal film for professionals in:

- Engineering & Prototyping – Precision, functional components

- Dental – High-accuracy models, trays, and appliances

- Manufacturing – Tooling, fit checks, and industrial modelling

Compatibility & Installation

- Use our FEP Size Finder to match the correct ACF sheet to your printer

- Follow our step-by-step How to Change Your FEP Film Guide

- Comes as 1 x XXL ACF Sheet, ready to trim and install into your vat

📄 Download Technical Data Sheet

Click below for full material specs, optical data, and durability performance.

Additional information

| Weight | 0.3 kg |

|---|

Why Choose Monocure3D Release Films?

• Tailored for UV Resin Printing: All our films are engineered to handle the unique challenges of UV-cured resins.

• Multiple Sizes Available: Each type is offered in various sizes to suit a wide range of printers and vats.

• Trusted Expertise: As pioneers in UV-cured resin technology, Monocure3D is committed to delivering reliable, high-performance solutions.

Whether you’re a beginner looking for a dependable release film or an expert pushing the boundaries of resin 3D printing, Monocure3D’s FEP, PFA, and ACF films provide the quality and consistency you need.

Release Films for 3D Printers – FEP, PFA (nFEP), and ACF

At Monocure3D, we offer a range of premium release films for resin 3D printers. Whether you’re looking for reliable FEP sheets, the enhanced durability of PFA (commonly referred to as NFEP), or the cutting-edge performance of ACF films, we’ve got you covered. Not sure which size you need? Use our FEP Size Finder to match the right film to your printer. Need help replacing your film? Check out our How to Change Your FEP guide for step-by-step instructions.

Optimised for UV Resin Printers

Tailored specifically for use in UV resin printers, these FEP sheets provide a flawless release layer, enhancing the quality of your prints.

Easy Installation

Follow our straightforward general directions for a hassle-free installation, ensuring a perfect fit and tension for optimal printing.

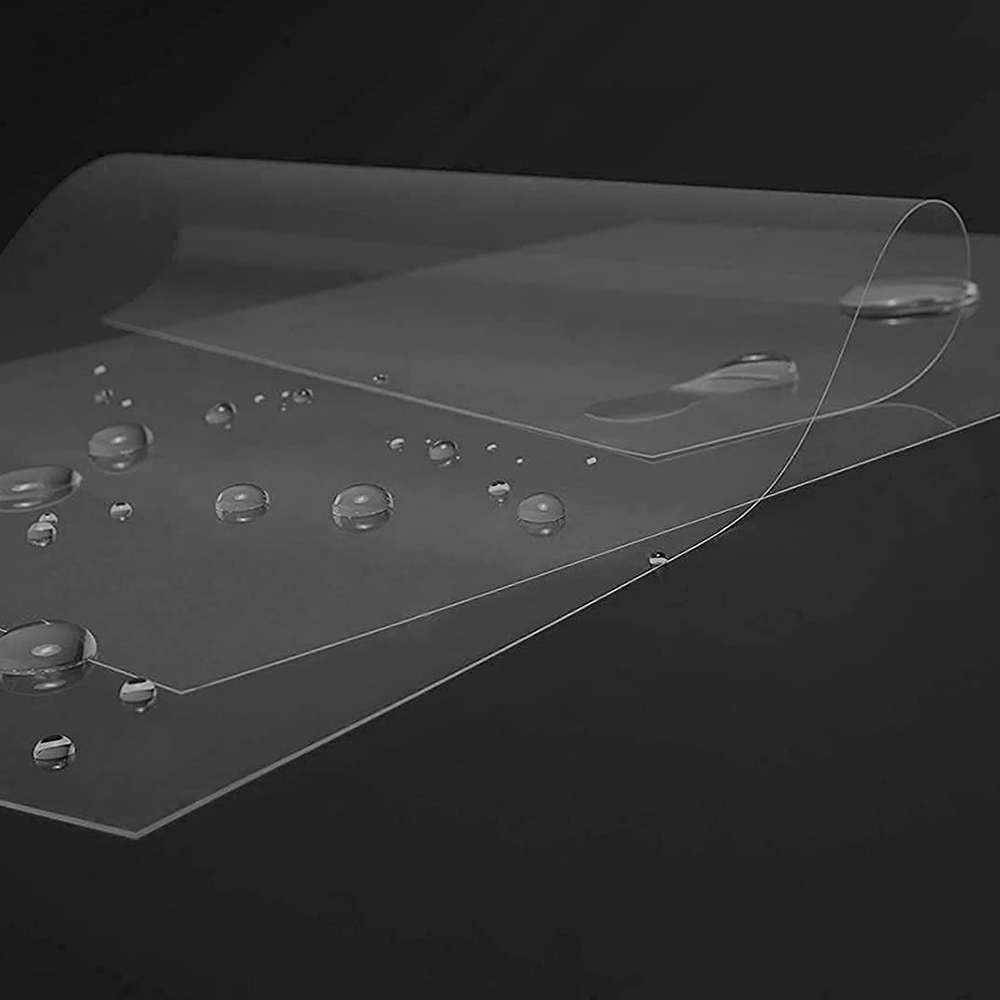

Durability and Clarity

Crafted for durability and clear visibility, these sheets maintain their integrity and transparency over multiple prints.

Maintenance Simplicity

Easy to clean and maintain with a simple wipe using a lint-free cloth and Isopropyl Alcohol (IPA), keeping your printing process efficient and spotless.

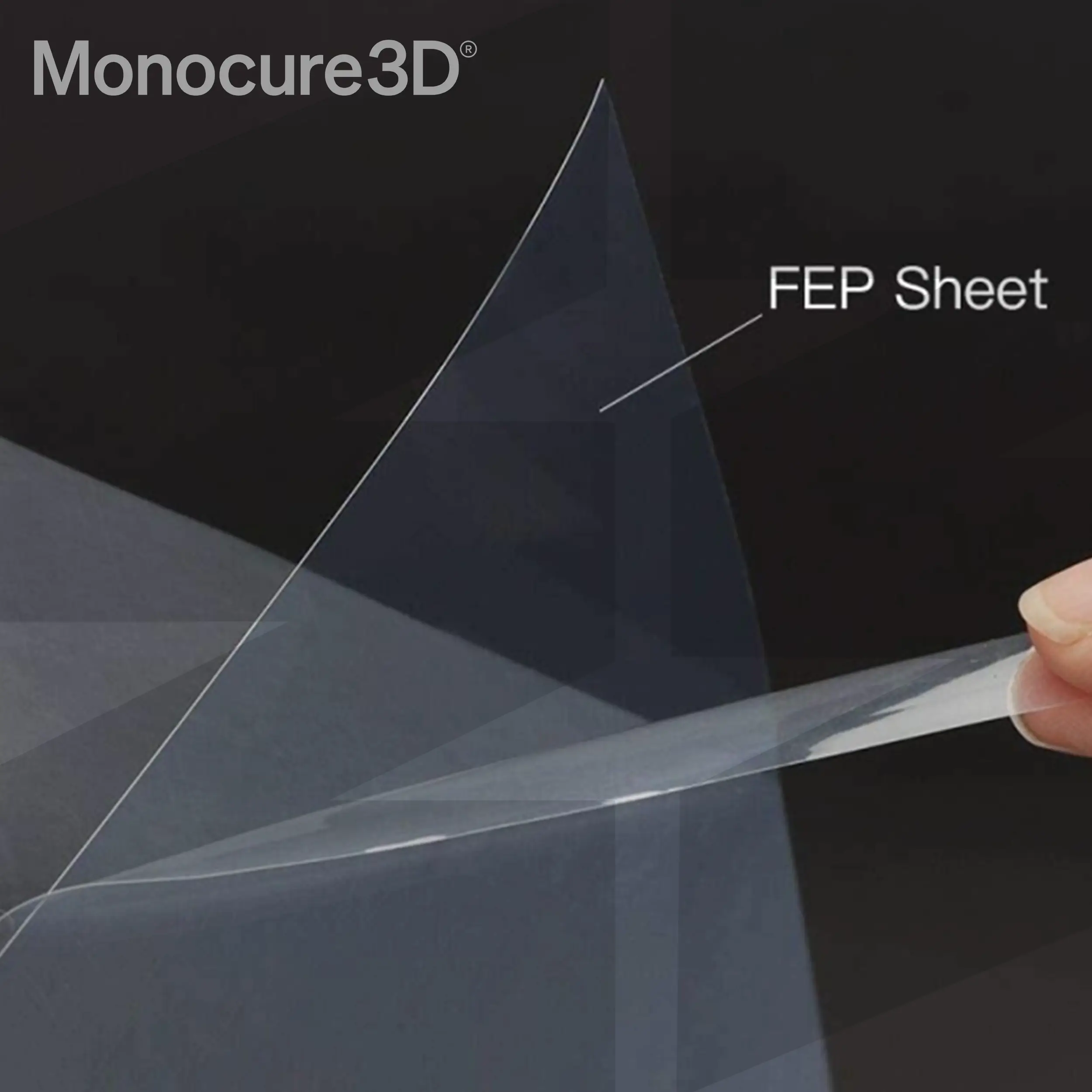

Genuine FEP – The Reliable Standard

Genuine FEP (Fluorinated Ethylene Propylene) film excels in various applications, mainly 3D printing. Known for its smooth surface, chemical resistance, and high insulating properties, it offers a robust solution for industrial and home-based printers. Its ability to maintain clarity under high temperatures and provide easy model release makes it affordable for producing detailed models. This makes FEP film a cost-effective and reliable choice for various printing projects.

Our Fluorinated Ethylene Propylene (FEP) sheets are a trusted choice for resin 3D printing, offering:

• Exceptional durability for prolonged use.

• Smooth resin release, reducing the likelihood of failed prints.

• Compatibility with a wide range of UV 3D printers.

Available in various sizes, Monocure3D’s FEP sheets are the go-to solution for standard release layer needs.

PFA (NFEP) Film – Enhanced Performance

PFA (nFEP) Film is a high-performance release film engineered explicitly for 3D printing, particularly suitable for light-curing technologies. Produced via a hot neck extrusion casting process, it features ultra-high purity PFA (nFEP) resin—a complex copolymer blend that offers exceptional non-stick properties and high-temperature resistance, crucial for the demands of 3D printing.

Polyfluoroalkoxy (PFA), also known as nFEP, offers a next-generation solution for resin 3D printers, providing:

- Superior Release Properties: Reduces adhesion issues, ensuring smoother and more consistent prints.

- Increased Durability: Resistant to higher temperatures and harsh chemicals, making it ideal for demanding applications.

- Extended Longevity: Outlasts traditional FEP films, providing reliable performance over extended use.

Choose PFA for a versatile, robust release layer that excels in challenging printing environments.

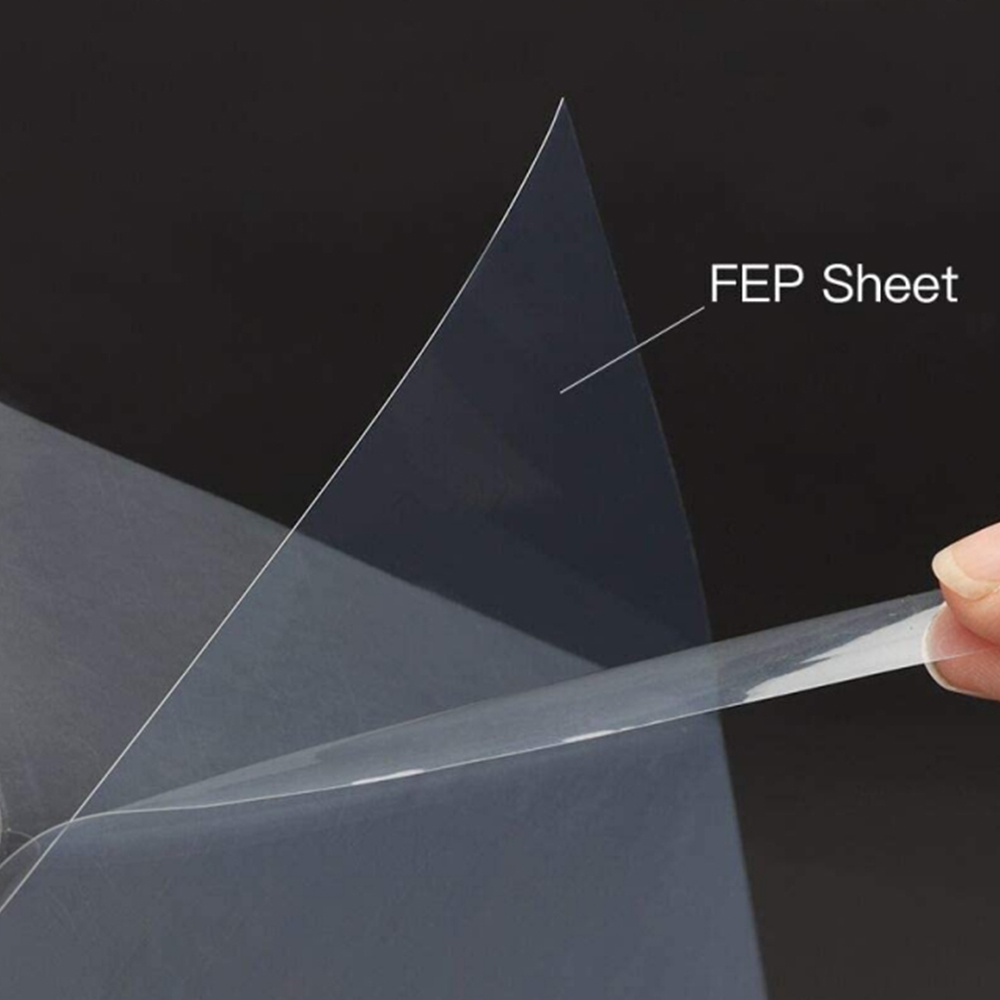

ACF – Advanced Copolymer Film

IMPORTANT: ACF Film has a gloss side and a matte side. The gloss side must face upwards towards the build plate. Incorrect installation can cause the film to tear and may damage your printer or LCD screen. Monocure3D will not be held responsible for damage caused by incorrect installation. Please download the TDS (Technical Data Sheet) for step-by-step installation instructions.

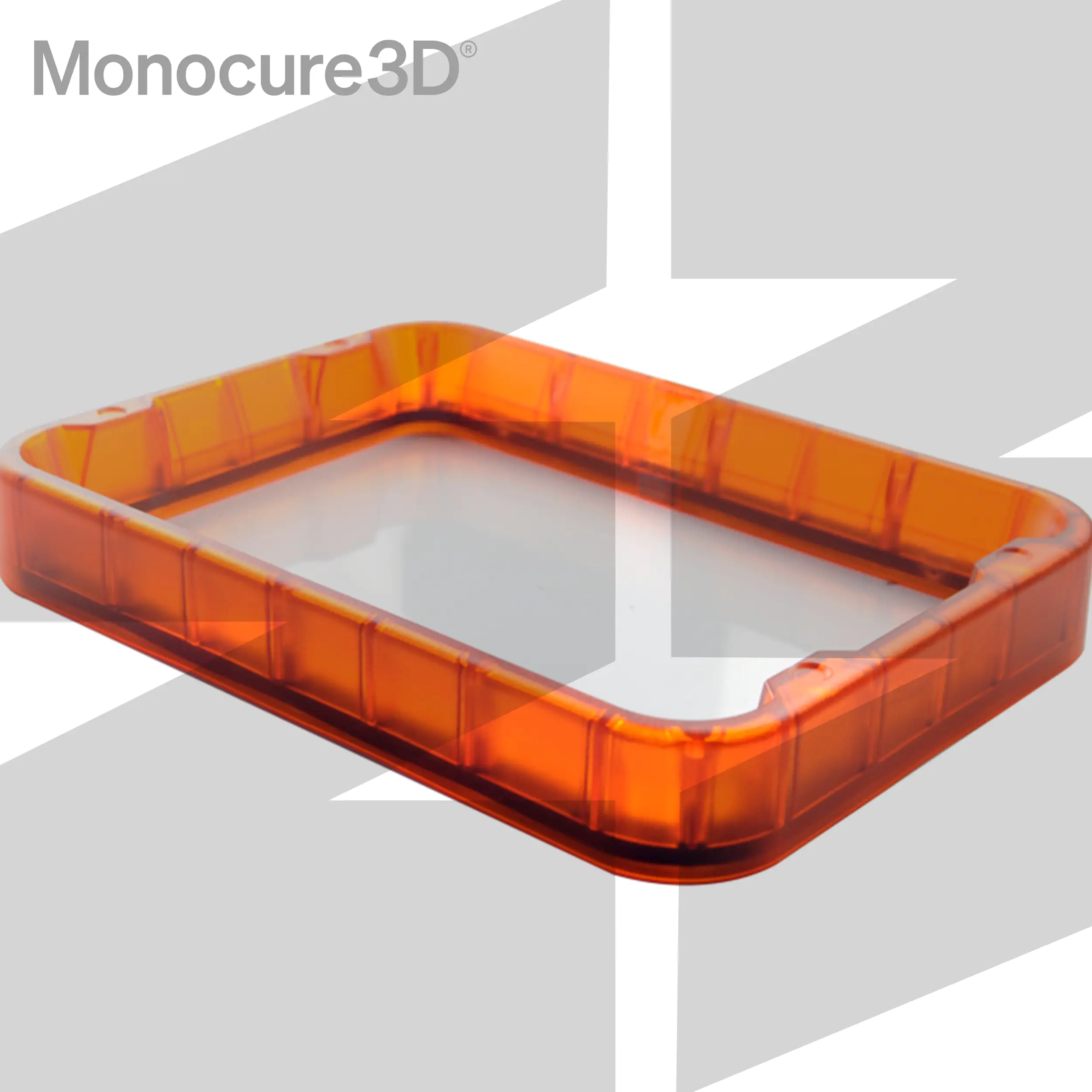

The ACF (Advanced Copolymer Film) is a high-end elastic separation film explicitly designed for bottom-up MSLA 3D printers. ACF offers excellent release properties and is made from a distinctive blend of FEP (Fluorinated Ethylene Propylene) and PTFE (Polytetrafluoroethylene) resins. It is softer and more flexible than traditional films, requiring careful handling. This film is particularly effective due to its significantly reduced peeling force and superior optical clarity, which boost printing success rates and minimise failures, especially with larger models or objects with extensive flat surfaces on the build plate.

Our Advanced Clarity Film (ACF) is designed for those who demand the highest level of performance from their resin release layer, offering:

- Exceptional Release Properties: Ensures effortless detachment of prints, even for highly detailed designs, reducing failed prints and improving consistency.

- Highly Flexible Design: Requires precise installation with a taut, drum-like tension for optimal performance.

- Delicate Material for Expert Use: Softer than FEP or PFA, ACF is more easily damaged and must be handled with extreme care. Avoid sharp objects in the vat to prevent tearing or puncturing.

Ideal for experienced users seeking precision and detail, ACF delivers unparalleled performance when used with care and expertise.

FEP, PFA & ACF | Release Layer Masterclass

Release Film Change: QUICK GUIDE

- Prepare: Set up a clean surface with a lint-free cloth and grab a new FEP sheet.

- Remove Old Sheet: Detach the vat, unscrew the frame, and discard the old sheet.

- Install New Sheet: Peel protective layers, align the sheet (ACF: Ensure Gloss Side faces towards build plate), and tighten screws evenly.

- Check Tension: Ensure the sheet is taut and sounds like a drum when tapped.

- Clean & Reinstall: Wipe the sheet clean, then reinstall the vat into your printer.

For a detailed walkthrough, check out the comprehensive step-by-step guide below or watch the video for visual instructions.

How to Replace a Protective Film – Step-by-Step Directions

Replacing a FEP sheet is a straightforward process when done with care. Follow these steps to ensure a successful installation:

1. Prepare Your Workspace

•Set up a clean, stable area free from dust and debris.

•Place a non-scratch, lint-free cloth on the surface to protect your printer parts and new FEP sheet.

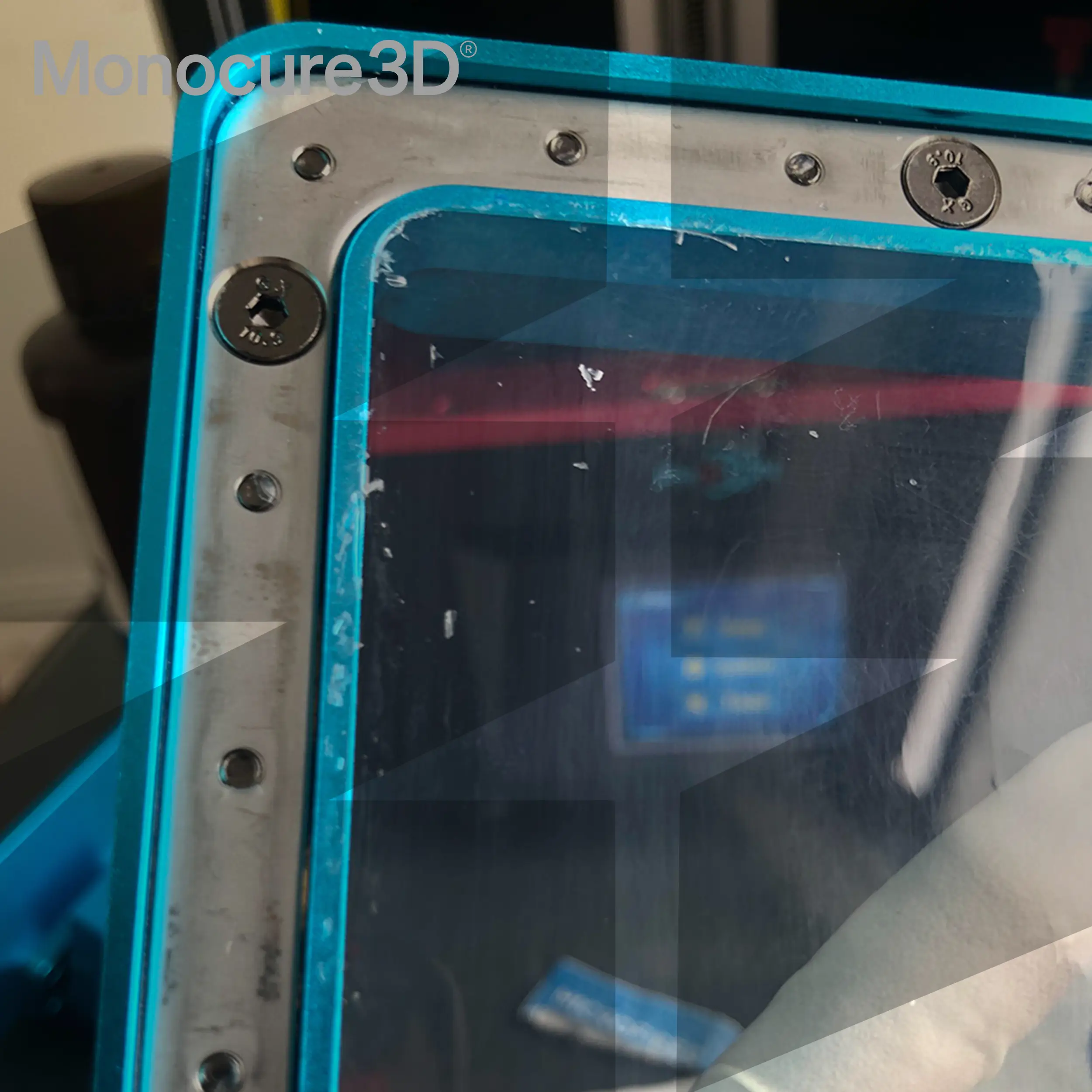

2. Remove the Old FEP Sheet

•Detach your printer’s vat according to the manufacturer’s instructions.

•Carefully unscrew and remove the frame securing the old FEP sheet.

•Gently peel away the used FEP sheet, avoiding sharp tools that could damage the vat or frame.

3. Prepare the New FEP Sheet

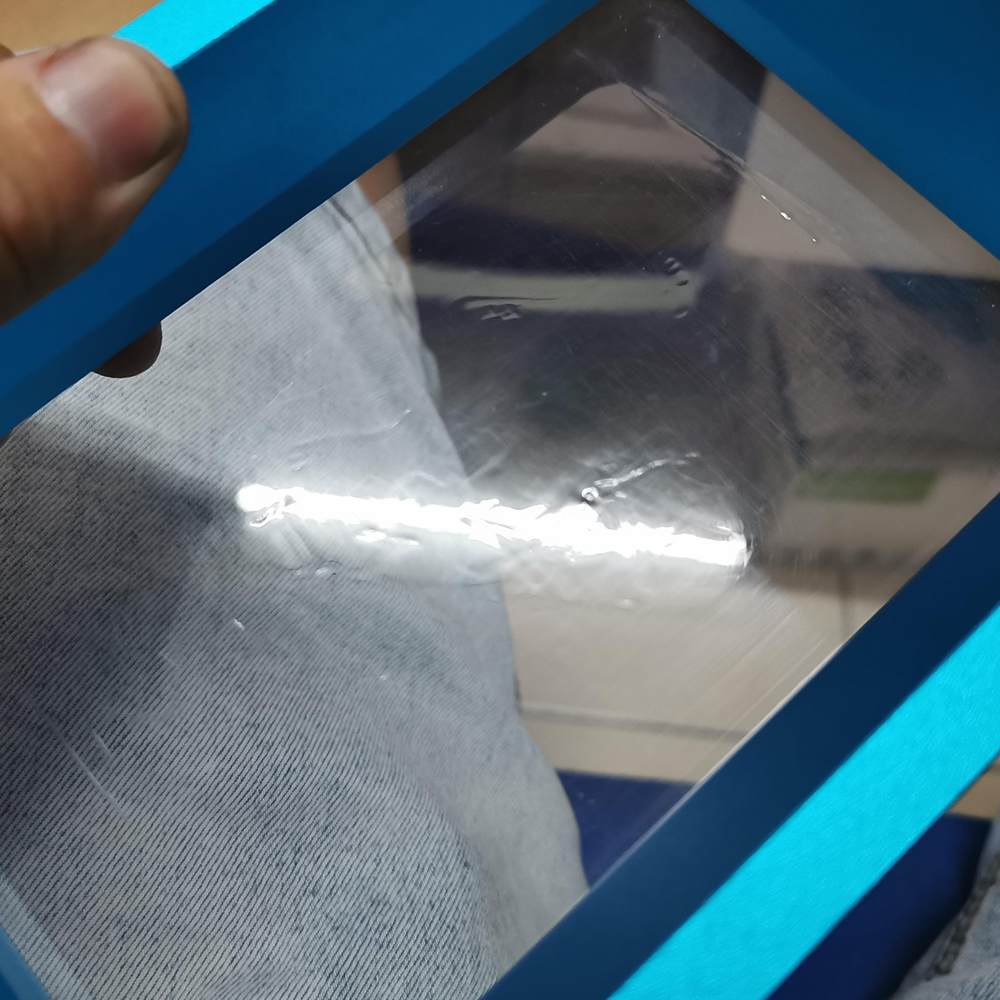

•Take one FEP sheet from its packaging and peel off the protective layer(s) on both sides. (NB: ACF only has protective film on the glossy side)

•Inspect the sheet for dust or particles, and clean if necessary using a lint-free cloth and isopropyl alcohol (IPA).

4. Install the New FEP Sheet

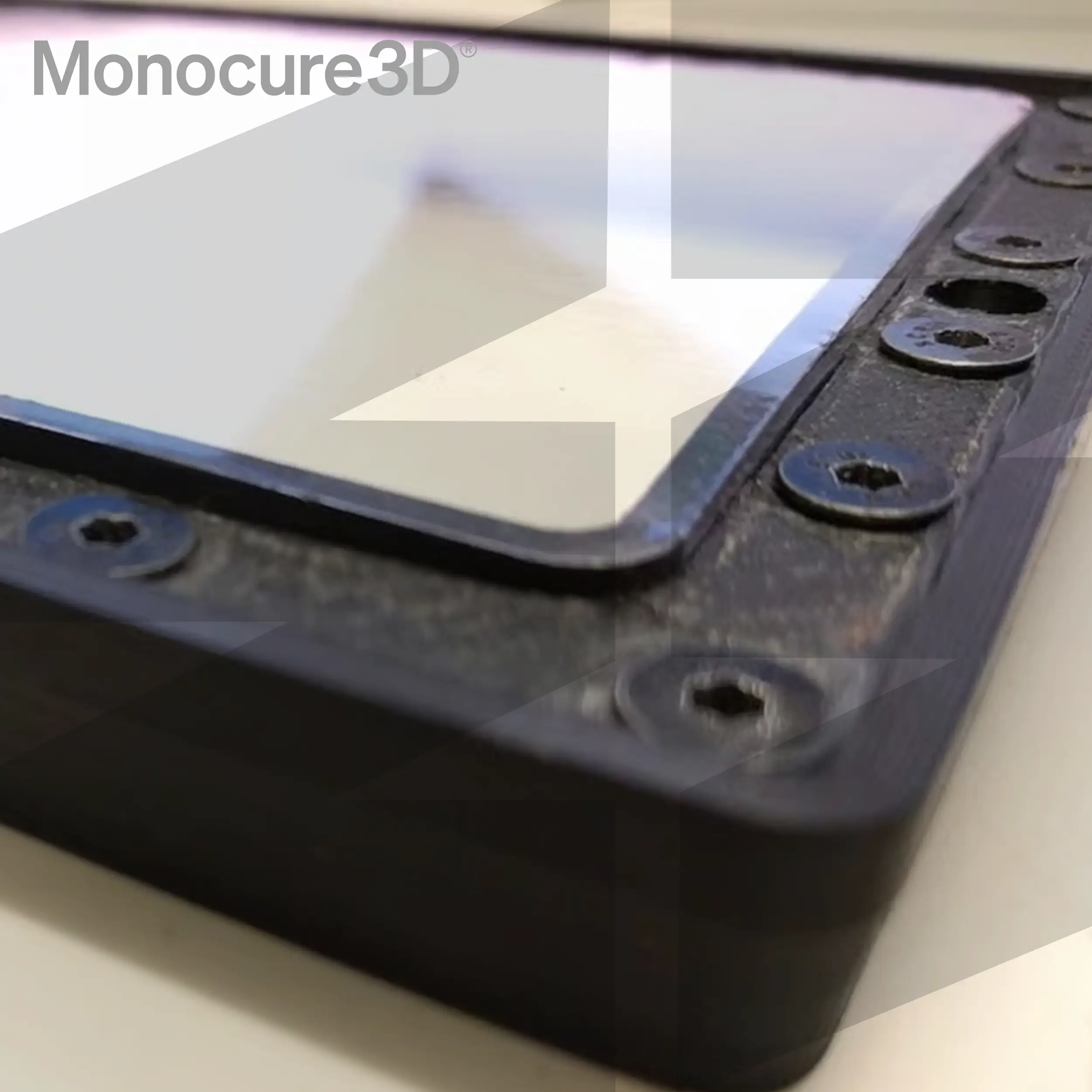

• Align the FEP sheet over the vat or frame, ensuring it covers the opening completely.

• If installing ACF, ensure that the glossy side of the film is facing up towards the build plate (and the matte side is facing the LCD screen)

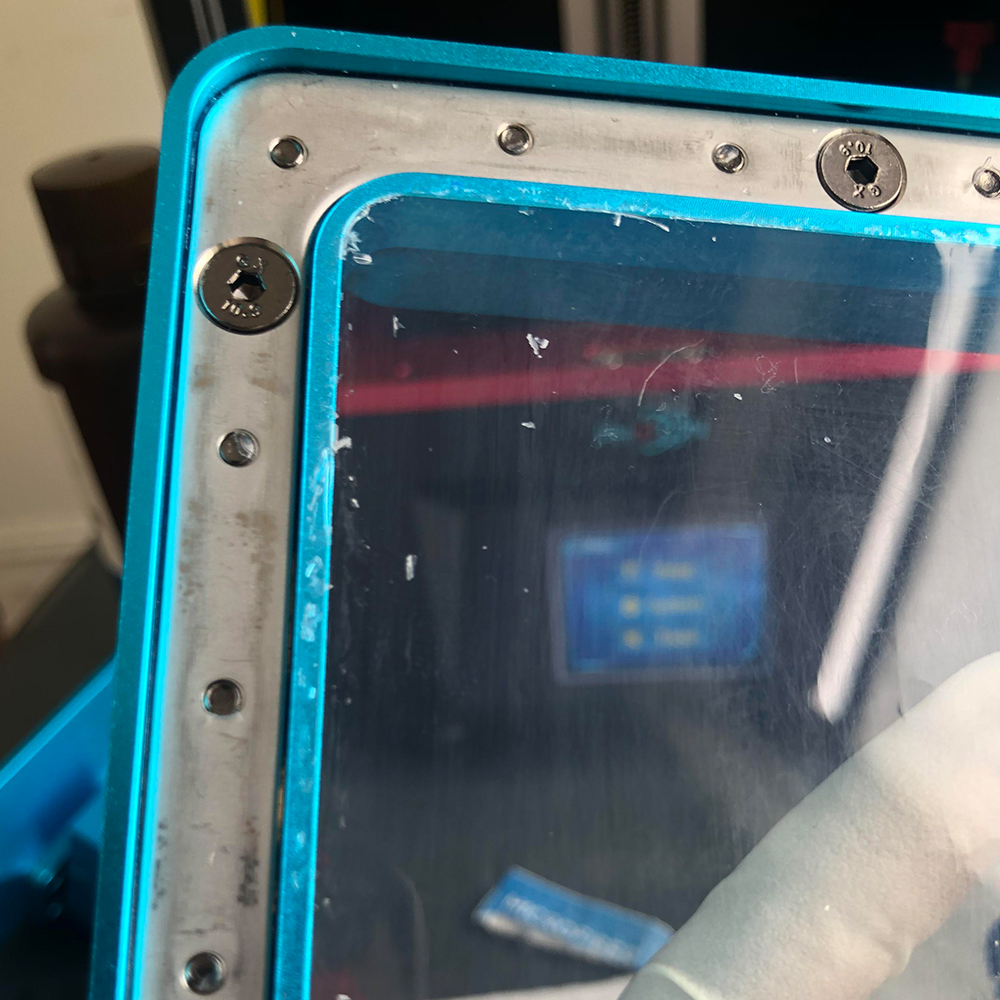

• Reattach the securing frame or screws, gradually tightening in a crisscross pattern to distribute tension evenly.

• The sheet should be taut and sound drum-like when tapped lightly.

5. Final Checks

•Inspect the FEP sheet for wrinkles or uneven tension, adjusting screws as needed.

•Ensure the vat and FEP sheet are clean before reinstalling them into your printer.

Tips for Best Results

•Avoid sharp objects near the FEP sheet to prevent scratches or tears.

•Replace your FEP sheet regularly to maintain print quality and avoid failures.

•Always handle the sheet by its edges to minimise contamination.

These steps will keep your printer running smoothly and ensure consistent print results.