Description

HeatResist Black Resin is engineered for high-temperature applications, making it ideal for industrial and engineering applications. Designed to withstand temperatures up to 150°C, it ensures reliable performance without shrinking, warping, or cracking over time, even under heat stress.

Its exceptional durability makes HeatResist Black Resin perfect for functional parts that demand consistent strength and stability in high-temperature environments. This resin delivers unmatched reliability for demanding applications, whether for prototypes or production components.

Key features:

- Withstands temperatures up to 150°C.

- No shrinking, warping, or cracking over time.

- It is ideal for functional parts requiring heat resistance and durability.

- Suitable for industrial and engineering applications.

- Reliable, consistent performance under heat stress.

Choose HeatResist Black Resin for applications requiring high heat resistance and long-lasting durability.

Additional information

| Weight | N/A |

|---|---|

| Bottle Size Options | 1kg, 5kg |

HeatResist Resin: Engineered for High-Temperatures

The HeatResist 3D printing resin range is designed for professionals who demand exceptional thermal performance and durability. Developed with advanced in-house technology, HeatResist offers superior resistance to temperatures up to 150°C, ensuring rigid, long-lasting prints with outstanding dimensional stability. Say goodbye to warping, shrinking, or cracking—this resin is engineered to deliver reliable results under heat stress.

HeatResist Resin is compatible with MSLA and DLP 3D printers and features low odour, ease of use, and consistent performance across every batch. It is also fully customisable using our innovative CustomMix system. Available in four professional-grade colours—White, Slate Grey, Clear, and Black—this range provides the versatility to meet various high-heat application requirements.

When precision and performance are critical, trust HeatResist Resin to deliver consistent, high-quality results for your most demanding projects.

Optimise HeatResist™ Resin for Perfect Results

Fine-Tune Settings

HeatResist 3D printing resin is optimised for MSLA and DLP printers, but achieving the best results requires proper calibration. Start with our recommended settings and fine-tune exposure times based on your printer and model complexity to achieve precise details and consistent performance, even in high-heat applications.

Customise Your Resin

HeatResist Resin is compatible with the CustomMix system, allowing you to tailor it to your project needs. Add colour toners for custom aesthetics, matting agents for unique finishes, or other additives for specialised properties. As results may vary, we recommend testing small batches to achieve the ideal combination for your application.

Maximise Durability

To fully realise HeatResist Resin’s exceptional heat tolerance and mechanical strength, evenly post-cure your prints using a 405nm UV light. Rotate the model during curing to ensure uniform exposure, and always post-cure for a minimum of 30 minutes for optimal results.

Minimise Waste

When switching colours or additives with HeatResist Resin, thoroughly empty and clean the vat to prevent cross-contamination. Use a resin filter to reclaim unused resin, ensuring a clean and efficient workflow while minimising material waste.

Precision and Performance with HeatResist Resin

HeatResist | Black

Our Black HeatResist Resin delivers precise, detailed prints with a bold, deep black finish. Engineered for exceptional opacity and thermal stability, it ensures consistent colour and durability, making it ideal for prototypes, industrial parts, and models requiring high heat resistance and sharp definition.

HeatResist | Clear

Our Clear HeatResist Resin offers crystal-clear transparency and exceptional versatility, making it ideal for applications such as lenses, light diffusers, and decorative items. It supports custom tinting with colour toners while maintaining excellent clarity, ensuring bubble-free, low-warping prints with a flawless finish.

HeatResist | Slate Grey

Slate Grey’s sleek, professional tone enhances surface detail while providing a refined, neutral aesthetic. Ideal for prototypes, functional components, and display models, this versatile colour offers an excellent base for painting or additional finishing, ensuring precision and durability under high-temperature conditions.

HeatResist | White

HeatResist White provides a clean, bright surface that precisely highlights intricate details. Its smooth finish is perfect for architectural models, functional parts, and prototypes. This resin offers excellent resistance to heat and yellowing, ensuring durable, long-lasting prints that maintain their professional appearance over time.

Expert Guidance, Anytime You Need It

The HeatResist resin range offers exceptional versatility, performing seamlessly with layer heights between 10 and 200 microns—design models as solid structures to maximise strength and durability for the best results. If hollowing is required, ensure the inclusion of well-placed drain holes to prevent resin from becoming trapped and compromising the print.

Visit our printer settings page for recommended starting parameters tailored to your machine. If your printer isn’t listed, we suggest using a calibration model to fine-tune your settings and achieve the best performance with HeatResist Resin.

At Monocure3D, we’re committed to supporting your success. Our Australian-made resins come with expert advice and guidance from a team with years of hands-on 3D printing experience. When you choose HeatResist, you’re not just investing in high-performance resin—you’re gaining access to professional support dedicated to helping you achieve outstanding results.

5 Steps to the Perfect Finish

For the best post-print results, clean your parts thoroughly with ResinAway®, our specially formulated cleaner designed to remove photopolymer resins from 3D-printed parts effectively. ResinAway® is a non-flammable, low-VOC alternative to IPA, offering a safer and more environmentally friendly solution for resin cleaning. Specifically formulated to break down and remove uncured resin effectively, it ensures a clean, efficient, and professional finish without damaging your prints. Unlike traditional solvents, ResinAway® is low in odour and gentle on both your parts and equipment, creating a safer and more pleasant workspace. For optimal results, rinse your parts with fresh water after cleaning before proceeding to post-curing.

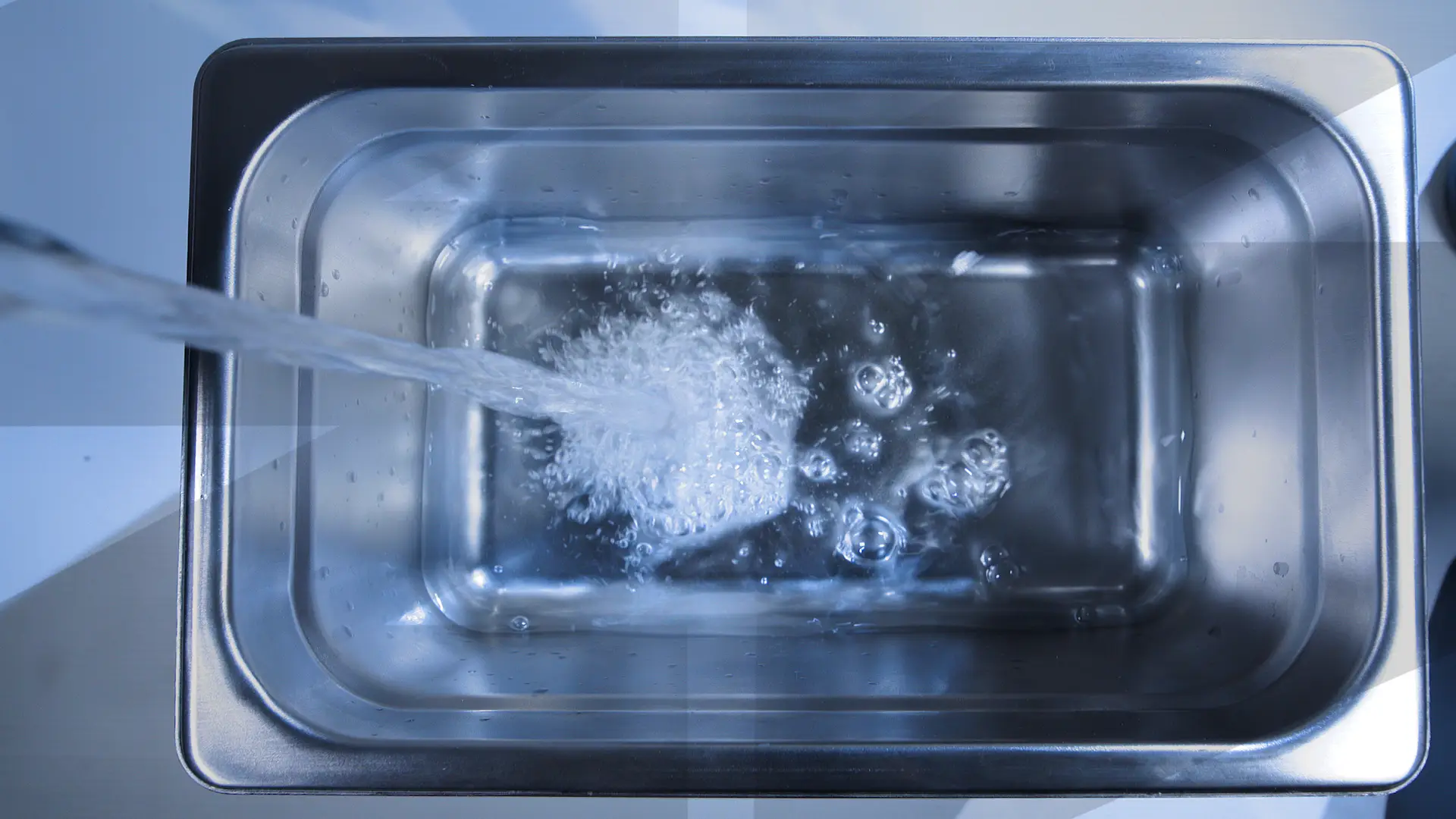

1. Pre-Wash: Start with a pre-wash bath of ResinAway® to remove uncured resin, using a soft brush to remove the excess resin.

2. Ultrasonic Bath: Follow up by placing the part in an ultrasonic cleaner filled with ResinAway® for 5-10 minutes to remove resin trapped in fine details.

3. Final Rinse: After cleaning, rinse parts with fresh water or IPA (for faster drying) to remove any remaining ResinAway® residue. Dry thoroughly using compressed air or a lint-free cloth to prevent surface imperfections. Be cautious—leaving IPA or ResinAway® residue on the part may result in surface cracking.

4. Post-Cure 30mins: To achieve optimal mechanical properties, HeatResist resin requires post-curing. Use a 405nm LED UV light and begin with a short cure of a few minutes to remove any remaining ResinAway® by rinsing with fresh water. Return the part to the curing chamber for at least 30 minutes to enhance tensile strength and durability.

5. Advanced Finishing (Optional): For parts exposed to external elements, apply a coat of paint to protect the surface and extend longevity. 3D Printed parts can be machined, sanded, or polished to create a tough, scratch-resistant finish. These steps ensure your HeatResist prints meet the highest professional standards.

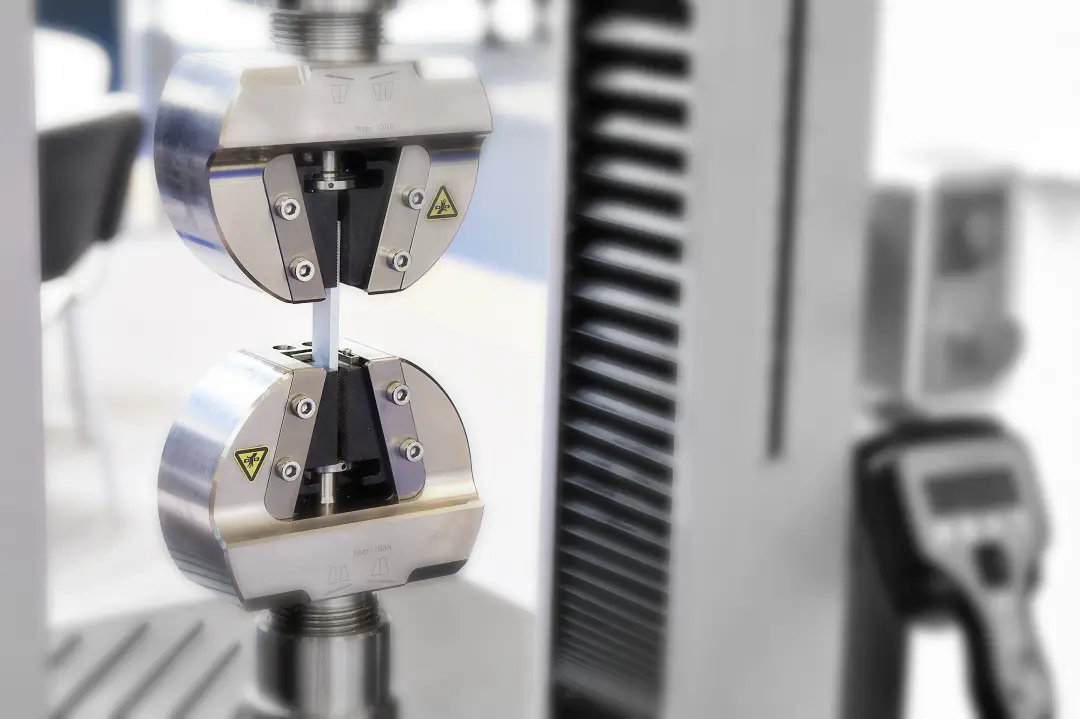

HeatResist™ MECHANICAL PROPERTIES

Method Code: ASTM D638-14

Product: Monocure3D HeatResist™ Resin (50μm)

Acceptance Code: Supply Findings

Specimen Type: Rectangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

M/HTR-4142GY, M/HTR-4152C, M/HTR-4153SLG, M/HTR-4154BK, M/HTR-4155W

Cross-Sectional Area (mm2)

26.47

Max Force (kN)

1.64

Tensile Strength (MPa)

48

Elongation at Break

2.6

Young’s Modulus (GPa)

0.95

Flexural Band Span (mm)

89.75

Max Load Applied (N)

360

Flexural Stress (MPa)

329

Shore Hardness (D)

97

Heat Deflection Temp

150°C @ 0.45MPa

HeatResist™ LIQUID PROPERTIES

SKUs

M/HTR-4142GY, M/HTR-4152C, M/HTR-4153SLG, M/HTR-4154BK, M/HTR-4155W

Viscosity

400-500cps @ 25°C(Brookfield RVT)

Odour

Low

Active Solids

100%

Shelf Life

36 months

Optimal UV Cure

405nm

Particle Size

< 10um

Cure Speed

2.5 secs (approx)

Storage

Dark Cool & Dry Place

Wash Up

RESINAWAY® or IPA