Description

Monocure3D IMPACT™ Resin is designed for those who demand exceptional strength, durability, and precision in their 3D prints. This industrial-strength resin is ideal for creating functional parts, prototypes, or models that withstand stress and impact without compromising detail or quality.

Engineered for professionals and 3D printing enthusiasts, IMPACT™ Resin delivers outstanding performance across a range of applications and consistently produces consistent results every time.

Key Features:

- Industrial-grade strength for durable 3D prints.

- Exceptional impact resistance for functional and stress-resistant parts.

- Tappable & Drillable without cracking or splitting.

- Precision formulation for detailed and accurate models.

- It is ideal for both professional and hobbyist applications.

- Consistent and reliable performance across various MSLA printers.

Choose Monocure3D IMPACT™ Resin for projects that require strength, durability, and precision in 3D printing.

Additional information

| Weight | N/A |

|---|---|

| Bottle Size Options | 1kg, 5kg |

IMPACT™ Resin | Strength Meets Performance

Monocure3D IMPACT™ Resin is the go-to solution for 3D printing functional parts that endure demanding environments. Engineered with exceptional strength, durability and impact resistance, it is ideal for creating components that must perform under stress, including industrial prototypes, functional models, and tools.

Whether you’re 3D printing prototypes for high-stress applications or parts requiring enhanced impact resistance, Monocure3D IMPACT™ Resin delivers superior toughness and reliability.

IMPACT™ Resin is designed to work seamlessly with all standard MSLA and DLP 3D printers, ensuring consistent results and reliable performance. Check our Printer Settings page for the best printing experience to confirm your printer’s compatibility.

If your printer isn’t listed, please don’t hesitate to contact us—our team is happy to assist you in finding the correct settings for your specific machine.

Bring your toughest projects to life with Monocure3D IMPACT™ Resin — the perfect resin for functional, hardwearing parts that stand the test of time.

Key Features That Make IMPACT™ Resin Stand Out

Exceptional Durability

Designed to withstand drops, impacts, and wear, this resin is perfect for creating parts that need to perform under stress.

High Strength and Toughness

Engineered for demanding applications requiring superior tensile strength and resistance to cracking.

Versatile Machinability

Tappable, drillable, and ideal for high-precision functional applications, offering a seamless post-processing experience.

CustomMix™ Compatibility

Enhance and customise your resin with our innovative CustomMix™ System for tailored results.

Designed for Tough Jobs: IMPACT™ Resin Applications

Functional parts, prototypes, and industrial components excel with Monocure3D IMPACT™ Resin. Its durability, strength and impact resistance make it ideal for demanding applications, delivering exceptional results for professionals and advanced users. Whether 3D printing tools, creating precision-engineered parts, or producing prototypes for testing, this resin ensures reliable performance and lasting quality.

Industrial Prototypes

Functional Components

Custom Tools and Fixtures

Durable End-Use Products

High-Impact Mechanical Parts

ProTips for Printing with IMPACT™ Resin

Print Solid

For maximum durability, print models as solid structures. If hollowing, add sizable drain holes and ensure walls are at least 5mm thick for strength.

Heavy Supports

To prevent print failures, use thicker supports on key areas, especially for larger or complex models requiring extra stability.

Layer Heights

Use a layer height of 50 microns or less to achieve high accuracy, fine details, and better structural integrity in your prints.

Post-Cure 60mins

Post-cure prints for at least 60 minutes under UV light to enhance strength, impact resistance, and long-term durability.

IMPACT™ Resin: Printing Guide for Optimal Results

IMPACT™ Resin is engineered for durability and precision, supporting layer heights from 25 to 200 microns. For best results, models can be printed solid or hollow. When printing hollow models, include adequate drain holes to remove trapped resin and ensure walls are at least 5mm thick for added strength.

To minimise warping or stress from adhesion to the FEP film, orient large flat surfaces at an angle and use heavy, well-placed supports to stabilise unsupported areas and maintain detail accuracy.

This resin performs optimally with a recommended normal layer exposure of 2.5 seconds when printing with a 50 microns (0.05mm) layer height on most MSLA 3D printers. Adjust settings as needed and use a calibration model to fine-tune your printer for IMPACT™ Resin. For guidance, refer to our detailed printer settings page.

For more tips, tricks, and updates, subscribe to our ProTips Channel and stay ahead with the latest insights from the M3D team.

Step-by-Step Guide to Finishing IMPACT™ Resin Prints

For best results with Monocure3D IMPACT™ Resin, follow these post-processing steps to achieve maximum strength, durability, and precision:

1. Pre-Wash: Use ResinAway® to remove uncured resin from your print. Gently scrub the surface with a soft brush in a container of ResinAway® to remove excess resin effectively.

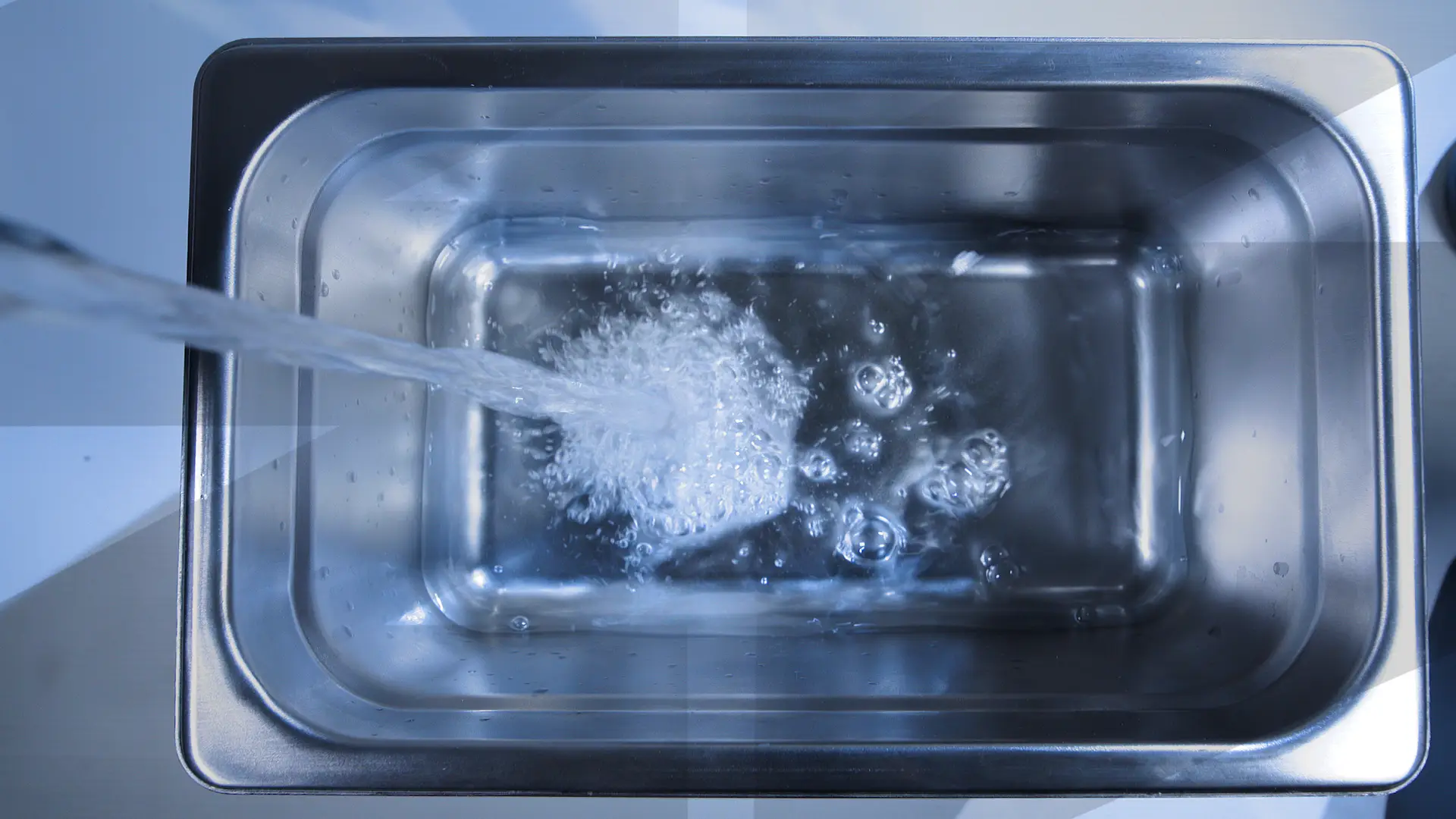

2. Final Wash: For hard-to-reach areas or fine details, place the part in an ultrasonic cleaner filled with ResinAway® for 3–5 minutes to dislodge any trapped resin.

3. Drying: Thoroughly dry the part using compressed air or lint-free cloth before post-curing. Ensure no residue from ResinAway® or IPA remains, which can affect the curing process.

4. Post-Curing: IMPACT™ Resin requires post-curing to achieve its final mechanical properties:

- A 405nm LED Ultraviolet curing chamber is used to cure the model.

- Cure for at least 60 minutes to maximise strength and impact resistance.

- Allow the model’s mechanical properties to improve over a few days after curing.

5. Finishing Touches (Optional): To protect and enhance your prints:

- Sand, machine, or polish your prints for a smooth finish.

- Apply paint or a protective varnish for enhanced durability and aesthetics.

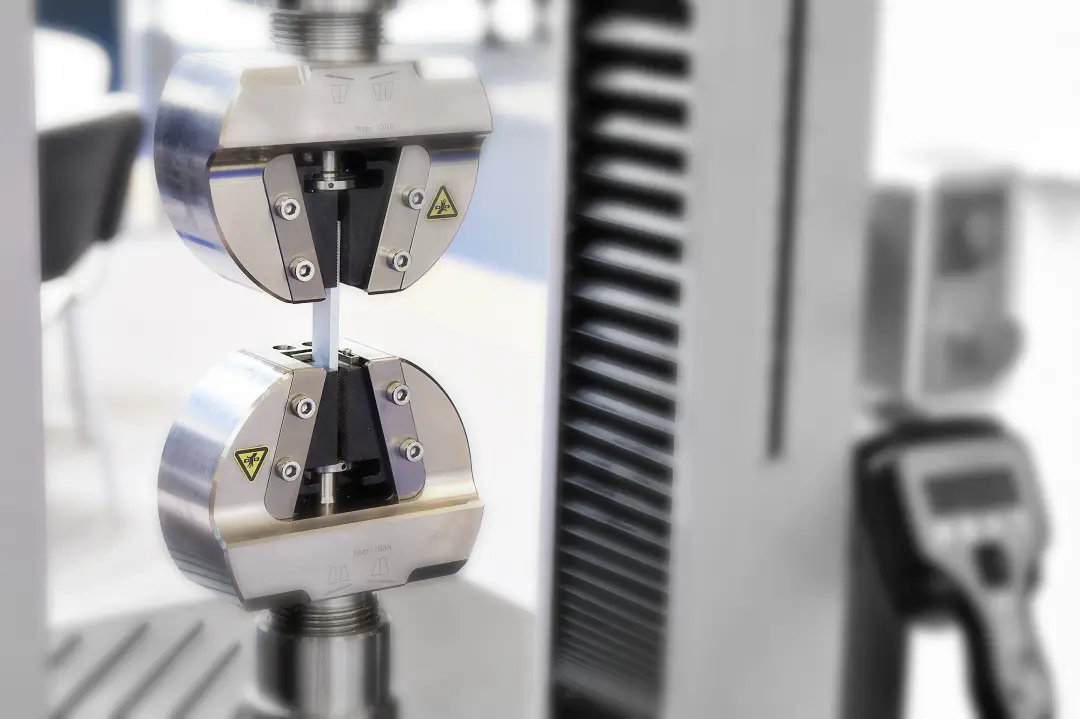

IMPACT™ MECHANICAL PROPERTIES

Method Code: ASTM D638-14

Product: Monocure3D IMPACT™ Resin (50μm)

Acceptance Code: Supply Findings

Specimen Type: Rectangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at Ambient Temperature

SKUs

M/INTI-4060BK, M/IMP-4140SLG, M/IMP-4160T

Cross-Sectional Area (mm2)

26.47

Max Force (kN)

1.64

Tensile Strength (MPa)

62

Elongation at Break

6

Young’s Modulus (GPa)

0.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

348

Shore Hardness (D)

94

Heat Deflection Temp

69°C @ 0.45MPa

MINI™ LIQUID PROPERTIES

Product Code(s)

M/INTI-4060BK, M/IMP-4140SLG, M/IMP-4160T

Viscosity

400 cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristic

Active Solids

100%

Shelf Life

36 months

UV Cure

405 nm (optimal)

Particle Size

< 10μm

Cure Speed

2-3 seconds

Storage

Dark cool, dry place

Wash Up

RESINAWAY® or IPA