PROTO™ Rapid Resin | Clear

PROTO Rapid Clear 3D Printing Resin is developed from our original Rapid Resin formulation — same trusted base, now with improved colour density and a fresh name. If you enjoyed working with Rapid, you’ll appreciate PROTO even more. We’ve reduced the price to make it easier to keep supporting Australian-made products, even when prototyping or printing basic models that don’t require the advanced strength and durability of our other resin ranges.

Clear PROTO™ Resin is an excellent choice for creating transparent prototypes, allowing designers to visualise internal structures or components. It pairs seamlessly with the CustomMix™ System, enabling you to mix it into vibrant whites or other custom colours.

Description

PROTO Rapid Clear 3D Printing Resin is developed from our original Rapid Resin formulation — same trusted base, now with improved colour density and a fresh name. If you enjoyed working with Rapid, you’ll appreciate PROTO even more. We’ve reduced the price to make it easier to keep supporting Australian-made products, even when prototyping or printing basic models that don’t require the advanced strength and durability of our other resin ranges. PROTO offers excellent precision and detail, making it ideal for cost-effective, high-quality prints across a wide range of creative and prototype models.

Key features:

- High-detail precision for detailed models.

- Optimised for fast, reliable printing with consistent results.

- Low odour for a more pleasant printing experience.

- Wide compatibility with various MSLA printers.

- It works seamlessly with our CustomMix™ system for added versatility.

Whether you’re testing product designs or crafting intricate prototypes, PROTO Clear 3D Printing Resin offers dependable results. It is fully compatible with the CustomMix™ system, enabling further customisation for your unique projects.

Additional information

| Weight | N/A |

|---|---|

| Bottle Size Options | 1kg, 5kg |

PROTO™ Resin: Precision and Speed for Rapid Prototyping

PROTO Resin has been specifically engineered for professional prototyping applications, optimised with MSLA printers that employ advanced LED array technology. This innovative formulation ensures a durable surface finish, providing the strength and detail required for demanding projects without compromising quality or reliability.

Ease of use is central to PROTO Resin’s design. A simple shake is needed before pouring and printing, with layer curing times as fast as 2-3 seconds on most monochrome LCD-equipped MSLA printers, making it ideal for rapid production cycles.

Post-curing for 30-60 minutes after cleaning is recommended to maintain long-term stability. This step ensures that printed models resist cracking or splitting over time. For detailed printer settings and calibration guidance, visit our dedicated printer settings page.

PROTO™ Resin offers a professional-grade solution for prototypes that demand precision, speed, and consistency.

Key Features of PROTO™ Resin

Precision Printing

Achieve exceptional detail and accuracy with every print, ensuring your prototypes meet the highest standards of design and function.

High-Speed Performance

Optimised for rapid curing, PROTO™ Resin ensures efficient production cycles with typical layer durations of just 2–3 seconds on monochrome LCD printers.

Compatibility with CustomMix™

Fully compatible with the CustomMix™ System, PROTO™ Resin allows you to personalise colours and properties, offering endless possibilities for your prototypes.

Effortless Usability

Ready to use after a quick shake, PROTO™ Resin requires no heating, simplifying your workflow and saving time.

PROTO™ Resin Colour Options: Tailored for Every Prototype

Shark Grey

Shark Grey’s balanced tone enhances visibility and detail, making it ideal for intricate prototypes. Its neutral shade provides excellent contrast for examining fine features and is a perfect base for painting. Shark Grey reduces visual distractions during the design process, helping you focus on the form and functionality of your prototype. It’s a versatile choice for design iterations and detailed models.

Dense Black

This solid, deep black achieves full opacity at just 2mm thickness, making it perfect for prototype models where black is the final colour, eliminating the need for additional painting. Dense Black is also excellent for miniatures, providing natural shadow details without requiring a black base coat. It’s a professional-grade colour for models with high contrast and definition.

Clear

Clear PROTO™ Resin is an excellent choice for creating transparent prototypes, allowing designers to visualise internal structures or components. It pairs seamlessly with the CustomMix™ System, enabling you to mix it into vibrant whites or other custom colours. PROTO™ is a great precursor for testing before using specialised resins like Tensile or PRO+ Ultra Clear for enhanced performance and durability.

Expert Tips for Printing with PROTO™ Resin

Prepare Your Resin

Ensure the resin is at room temperature and well-mixed before use. Shake the bottle thoroughly to achieve consistent results across your prints.

Calibrate Your Printer

Use calibration models to fine-tune your printer settings for PROTO™ Resin, ensuring high accuracy and precision.

Post-Cure for Durability

After cleaning, post-cure your models under 405nm UV light for 20–30 minutes to enhance strength and long-term stability.

Use Supports Strategically

Angle models on the build plate and use well-placed, dense supports to prevent warping and ensure flawless prints.

Optimising Your Prints with PROTO™ Resin

PROTO™ Resin offers remarkable versatility, supporting layer heights from 5 to 200 microns for various applications. For optimal results, models should generally be sliced as solid. If hollowing is necessary, ensure properly placed drain holes to avoid trapping resin and improve cleaning efficiency.

When positioning your model, angle it on the build plate to minimise large flat areas that could lead to warping or deformation due to FEP film adhesion. Use dense, strategically placed supports to address unsupported areas to maintain structural integrity and print success.

PROTO™ Resin is engineered for speed, often requiring faster print settings than other resins. It’s essential to adjust your printer settings accordingly. Utilise a calibration model on our website to fine-tune your printer for the best results.

For additional guidance, visit our dedicated printer settings page to see if your printer is listed, providing a reliable starting point for dialling in PROTO™ Resin.

Post-Processing Guide for PROTO™ Resin

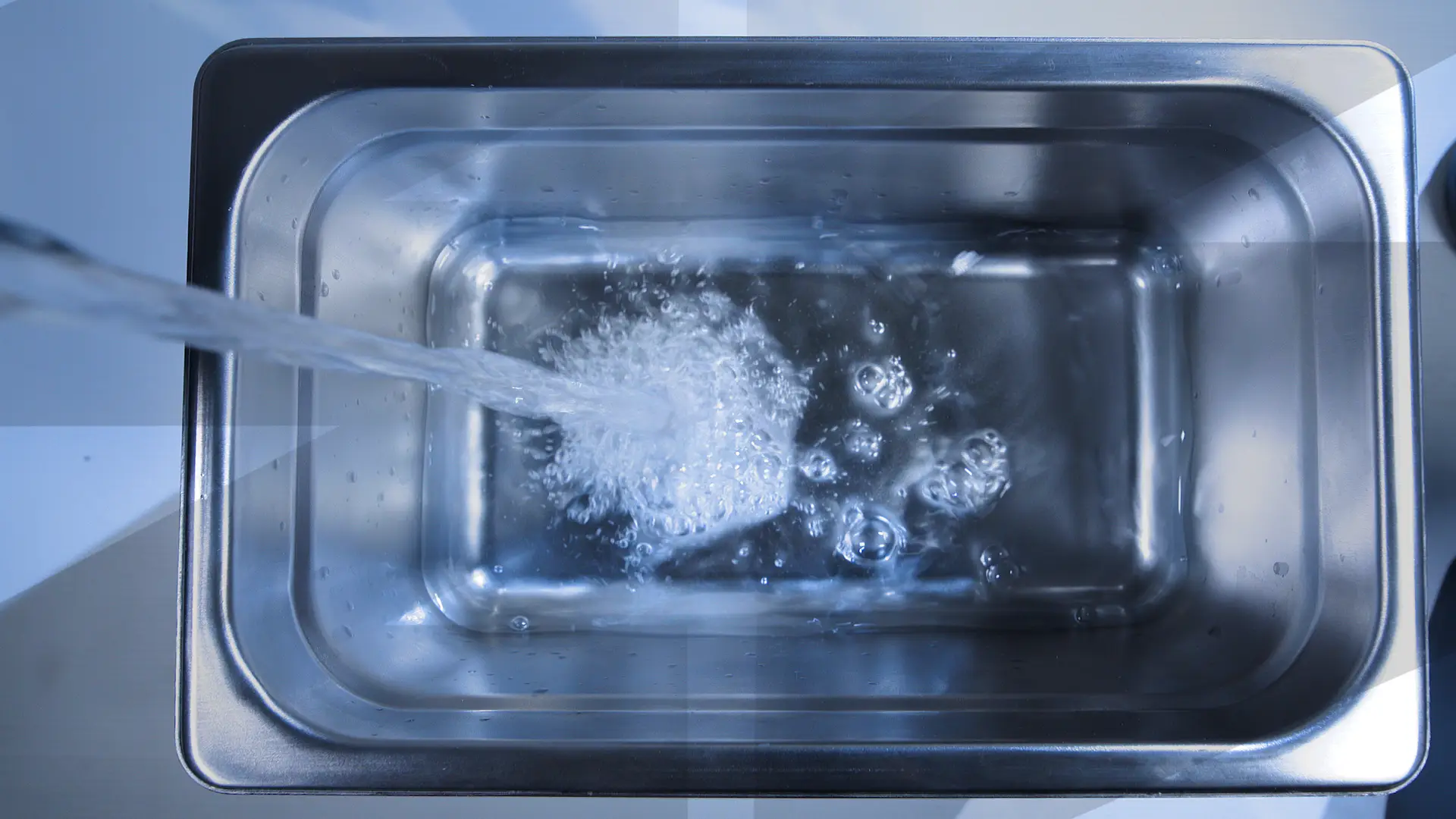

1. Cleaning with ResinAway®: After printing, immerse your model in a pre-wash bath filled with ResinAway®. Use a soft brush to remove uncured resin from the surface gently. For finer details, place the model in an ultrasonic cleaner with ResinAway® for 5-10 minutes to effectively clean hard-to-reach areas.

2. Drying the Model: Ensure the model is thoroughly dried by using compressed air or patting gently with a lint-free cloth. Avoid leaving excess IPA or ResinAway® on the part, as this could lead to surface cracking during curing.

3. Post-Curing for Strength: Use a 405nm LED UV light for post-curing. Start with a brief exposure to cure the surface, then rinse the model with fresh water to remove any ResinAway® residue. Return the model to the curing chamber for a minimum of 30 minutes to enhance its tensile strength and durability.

4. Finishing Touches (Optional) For models exposed to external elements, applying paint to the surface improves longevity and protection. Components can be machined, sanded, or polished to create a tough, scratch-resistant surface, making them suitable for professional use.

PROTO™ Resin: Liquid and Mechanical Properties at a Glance

MECHANICAL PROPERTIES

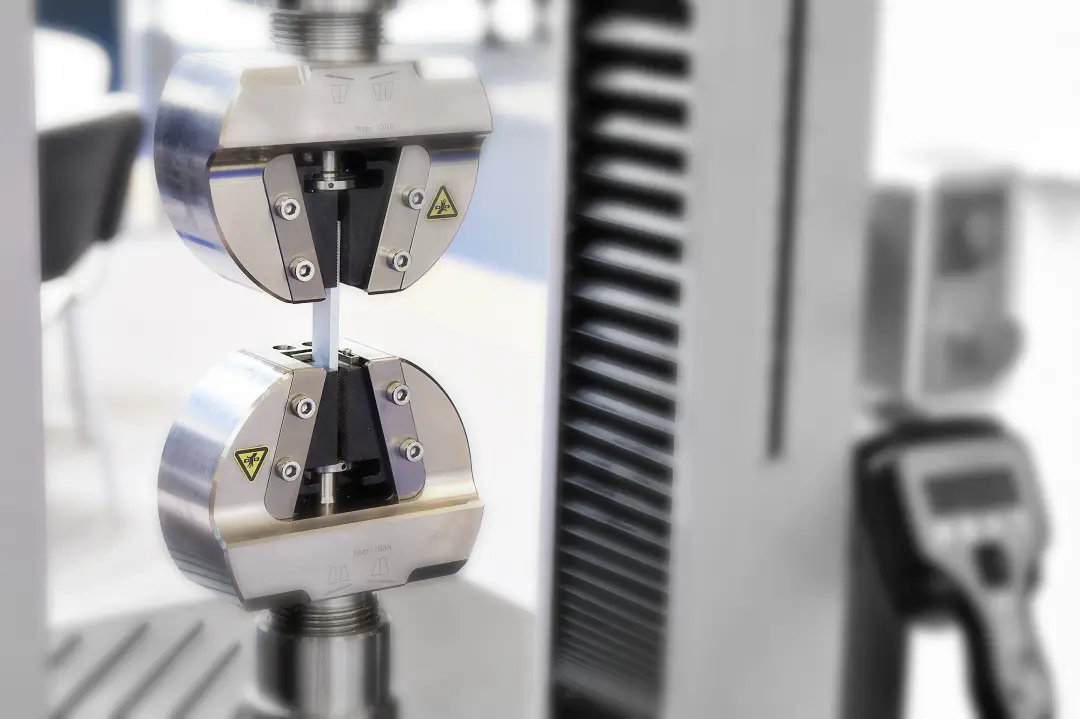

Method Code: ASTM D638-14

Product: Monocure3D PROTO™ Resins (25μm)

Acceptance Code: Supply Findings

Specimen Type: Rectangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at ambient temperature

SKUs

M/PTO-4146C, M/PTO-4147SG, M/PTO-4148BK

Cross-Sectional Area (mm2)

25.29

Max Force (kN)

1.64

Tensile Strength (MPa)

47

Elongation at Break

3.0

Young’s Modulus (GPa)

1.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

124

Max Flex Strain (mm/mm)

0.5

Shore Hardness (D)

75

Heat Deflection Temp

55°C @ 0.45MPa

LIQUID PROPERTIES

SKUs

M/PTO-4146C, M/PTO-4147SG, M/PTO-4148BK

Colour(s)

Shark Grey, Black & Clear

Viscosity

500cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

405nm (optimal)

Cure Speed

2.5 secs

Storage

Dark cool & dry place

Wash Up

RESINAWAY® or IPA