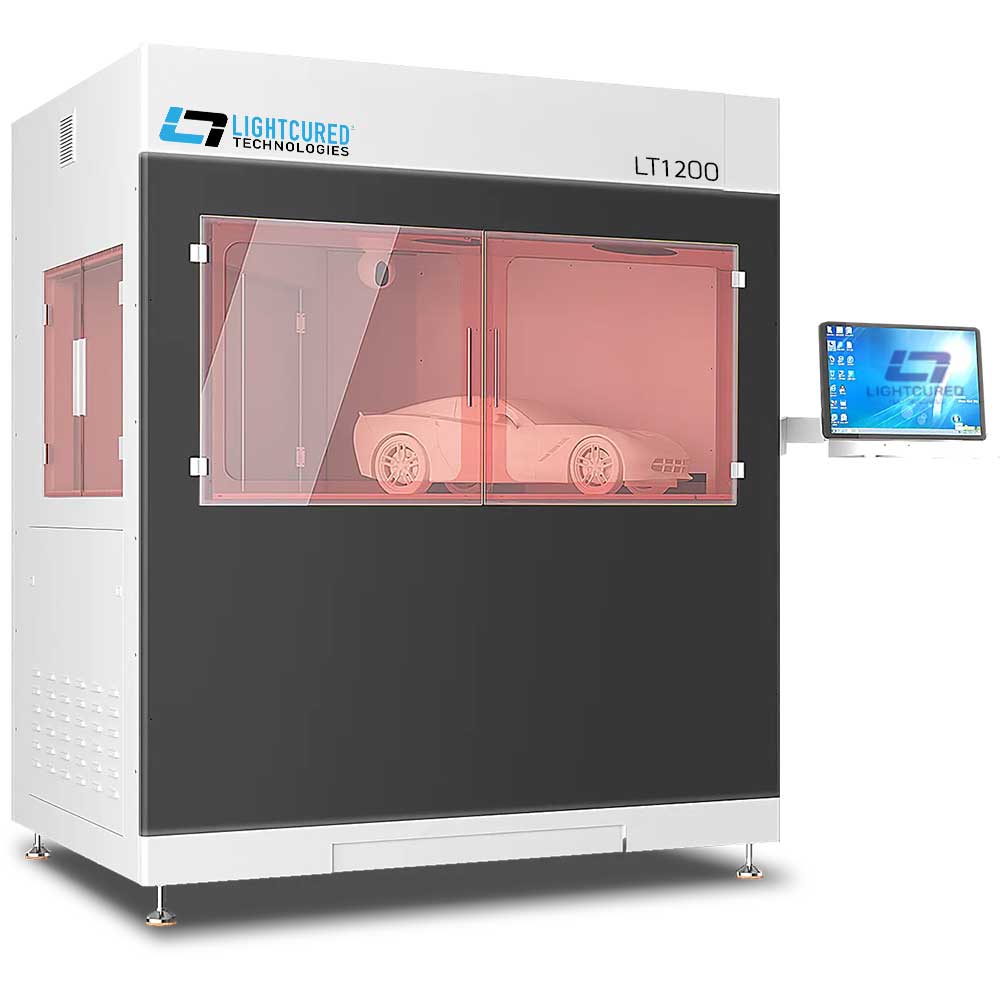

Industrial SLA 3D Printer | Optima LT1200

Our Optima Series SLA printers are engineered to work seamlessly with Monocure3D’s resin range, delivering reliable, large-format results at an affordable entry point. Built for industrial applications, each model is tested for compatibility and performance with our proven resins, giving you a complete workflow you can trust.

For pricing and availability, please contact us here.

Description

The Optima LT1200 is a large-format industrial SLA 3D printer designed for applications where scale, accuracy, and reliability are essential.

With a 1200 × 600 × 500 mm build volume, it enables the production of substantial components in a single build, reducing the need for sectioning and post-assembly. It is equally suited to batch production of multiple parts, making it ideal for tooling, casting patterns, engineering prototypes, and specialised manufacturing projects.

A customised UV laser paired with a high-end digital galvanometer delivers a precise 0.1 mm laser spot for fine feature definition and consistent dimensional control. Scan speeds of up to 6,000 mm per second support efficient production across the full platform area.

Laser-based liquid-level detection helps maintain stable processing during extended builds, particularly for large-format parts. The removable resin tank simplifies maintenance, and the industrial-grade construction ensures durability in demanding production environments.

The LT1200 is compatible with all Monocure3D resin systems, with customised resin formulations available on request to suit specific applications.

Talk to us today about your production requirements.

+ Massive 1200 × 600 × 500 mm build volume, customisable

+ Precision 0.1 mm laser spot for fine feature accuracy

+ High-end digital galvanometer with scan speeds up to 6,000 mm per second

+ Layer thickness support from 0.05 mm to 0.15 mm

+ Laser liquid-level detection for consistent processing

+ Compatible with all Monocure3D resins and customised options

+ Removable and replaceable resin tank for easier maintenance

+ Industrial-grade construction for durability and stability

+ Australian-based technical support

+ Open supply model with no lock-in contracts

+ Finance options available on request

Contact our 3D printing experts for a free consultation

| Product model | Optima LT1200 |

| 3D technology | Stereolithography (SLA) |

| Machine dimensions | 1800 × 1300 × 2300 mm |

| Gross weight | Approx. 1500 kg (excluding materials) |

| Laser | Customised UV laser |

| Galvanometer | High-end digital galvanometer |

| Spot size | 0.1 mm |

| Scanning mode | Galvo scanning |

| Scanning speed | Up to 6,000 mm/s |

| Liquid level detection | Laser level sensor |

| Compatible materials | Monocure3D Resins |

| Build volume | 1200 × 600 × 500 mm (customisable) |

| Layer thickness | 0.05–0.15 mm |

| Printing speed | Max 180 g/h |

| Resin tank | Removable and replaceable |

| Power supply | 220 V, 50 Hz |

| Rated input power | 650 W |

| Warranty | 12 months |

When you purchase an SLA printer through us, you are not simply buying a machine. You are investing in a complete printing solution backed by local expertise and ongoing support.

We will ensure the printer is correctly configured, calibrated and operating as expected. If we recommend a specific model for your application, it is because we are confident it will perform in your environment and deliver consistent results.

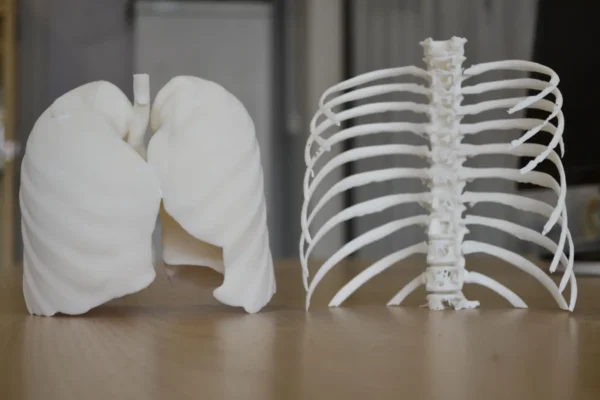

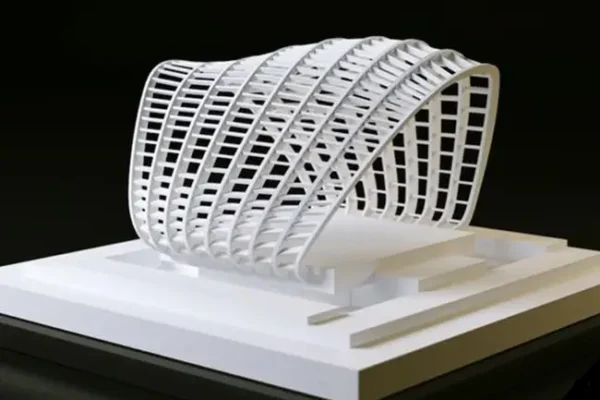

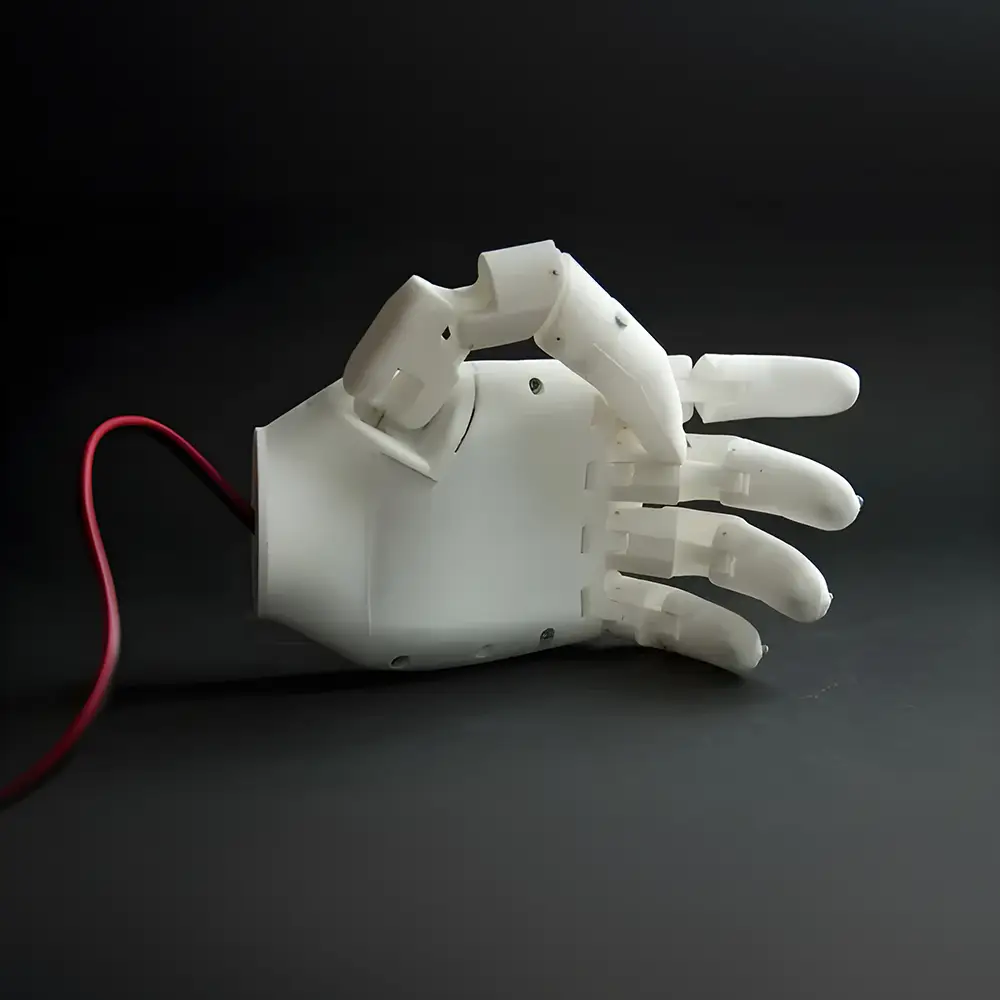

As resin manufacturers, we have the advantage of controlling the material side of the equation. Our resins are tested and validated to work with the printer’s light engine and wavelength. If required, we can fine-tune formulations to suit your application, whether that is architectural models, film props, dental models or industrial components.

We will assist with initial setup, recommended print settings and resin selection. If adjustments are needed, we work through them methodically to achieve stable, repeatable performance.

Service and support are handled locally. We provide technical assistance, maintenance guidance, and access to spare parts. Should an issue arise, we take responsibility for resolving it quickly and professionally.

Our objective is simple. The printer must work reliably in your business. We want you to print successfully and consistently, because long-term resin supply and ongoing partnership depend on it.

Book a consultation to discuss your workflow

All SLA printers we supply are backed by a comprehensive manufacturer’s warranty and supported locally by our team. Warranty terms vary by model and component, and full details are provided at the time of purchase.

As your Australian supplier, we act as your first point of contact for all technical matters. This means you are not dealing with overseas time zones or uncertain service channels. If a fault occurs, we will guide you through diagnosis and coordinate repair, replacement parts or return to base service where required.

We provide:

- Initial setup guidance and configuration support

- Assistance with slicer settings and print optimisation

- Advice on maintenance and routine servicing

- Access to genuine spare parts and consumables

- Remote troubleshooting and technical support

Where applicable, we can arrange on-site service or structured remote sessions to resolve complex issues efficiently.

Because we also manufacture resin locally, we can support the entire workflow. If a print issue arises, we assess both hardware and material variables to identify the root cause. This integrated approach reduces downtime and avoids unnecessary part replacement.

Our goal is straightforward. The printer must operate reliably in your environment, and you must have clear access to practical, knowledgeable support when you need it.

Contact us for full specifications and pricing

Prototyping | Manufacturing | Tooling | Engineering | Casting | Large-Format

The Optima Series, Industrial SLA 3D Printers

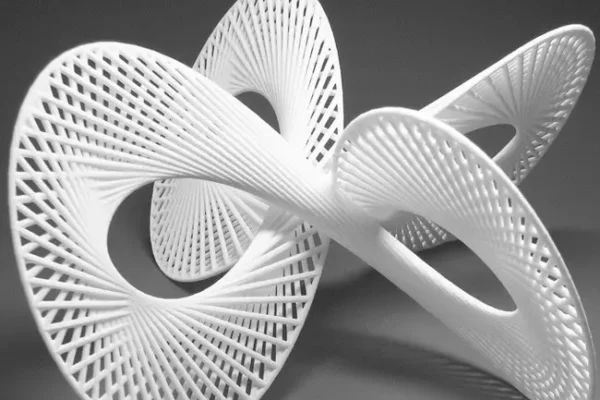

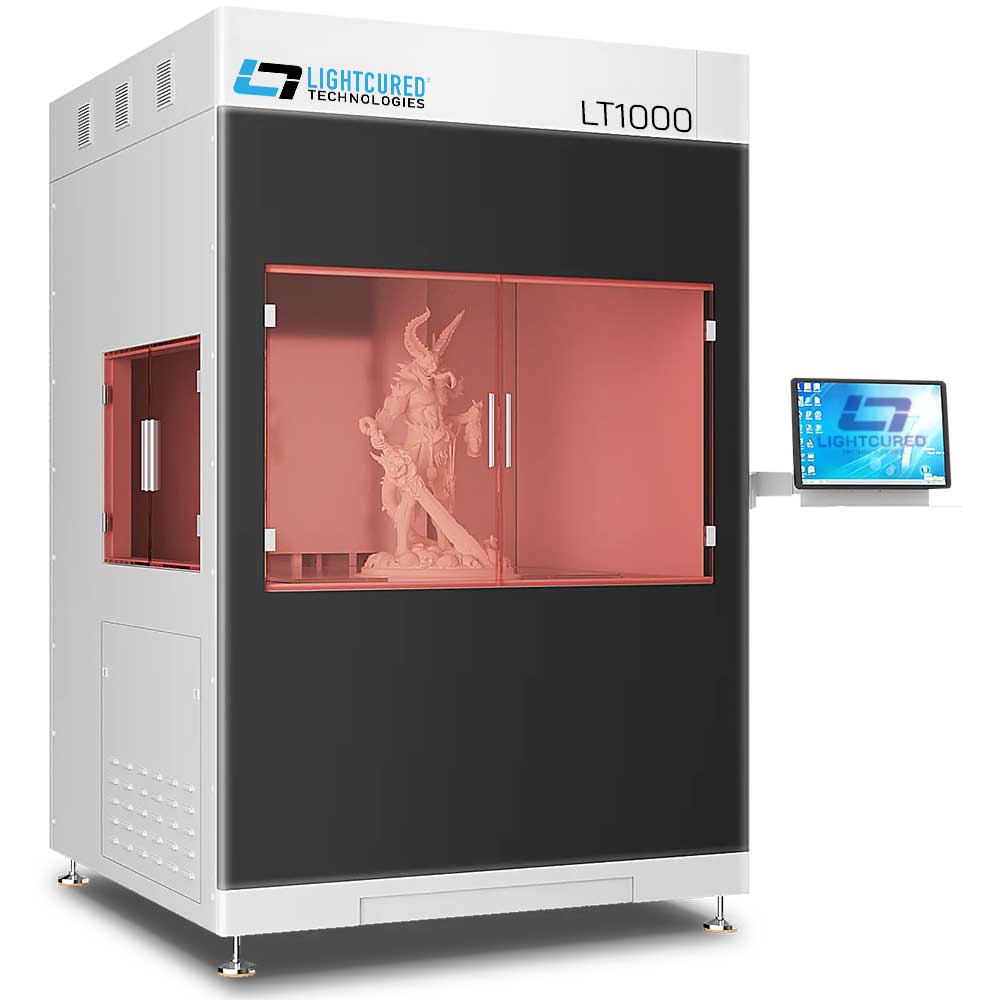

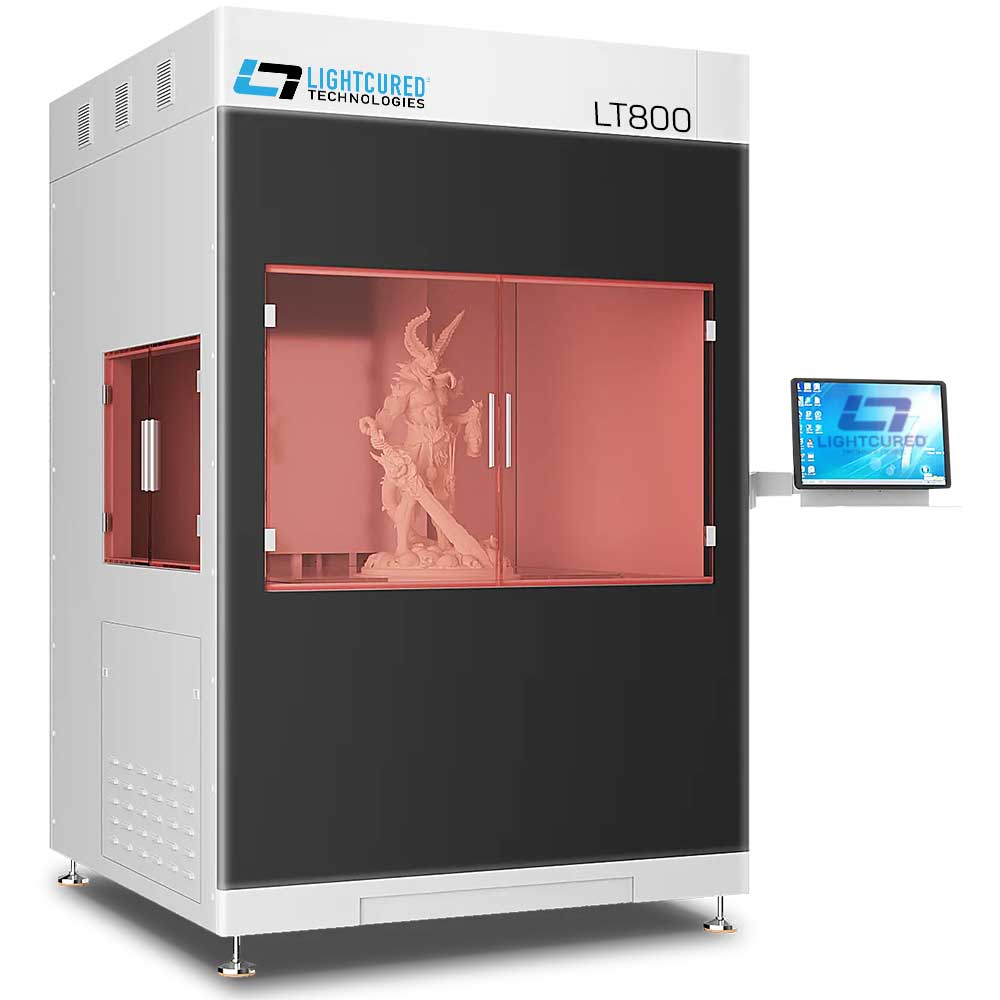

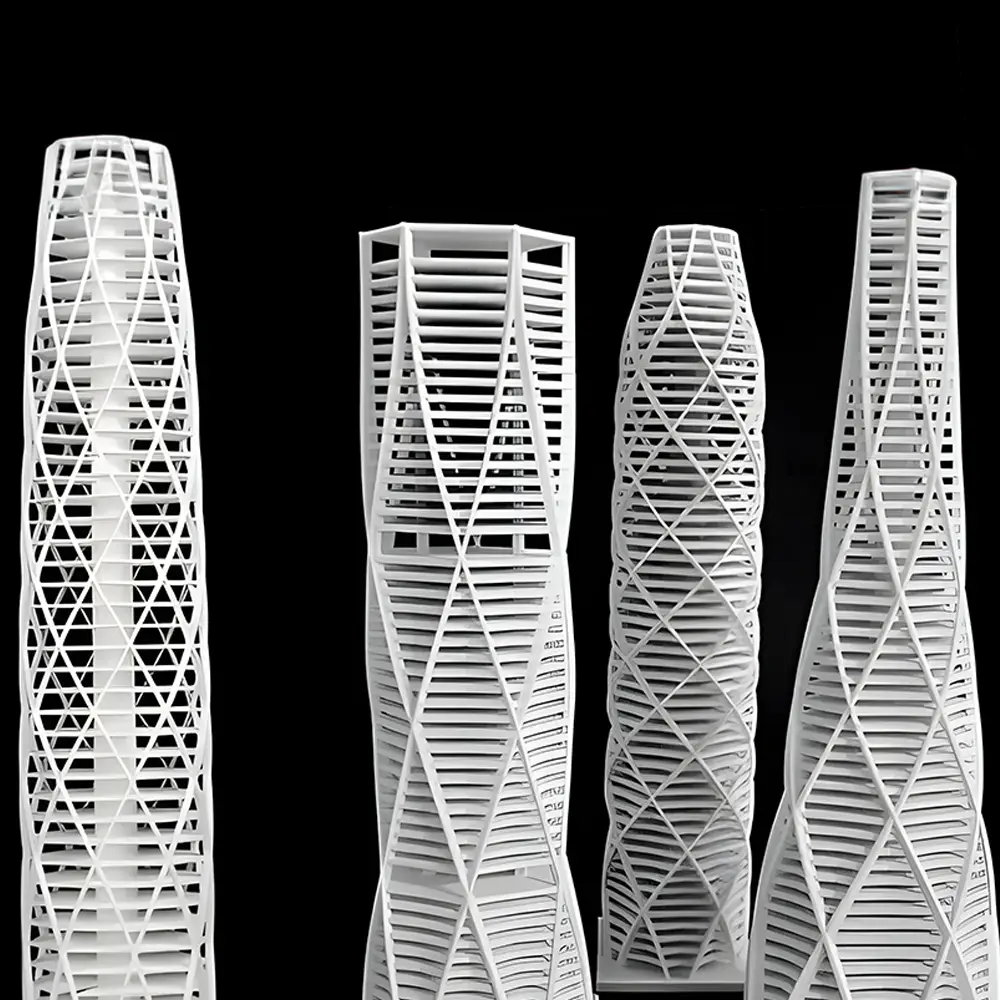

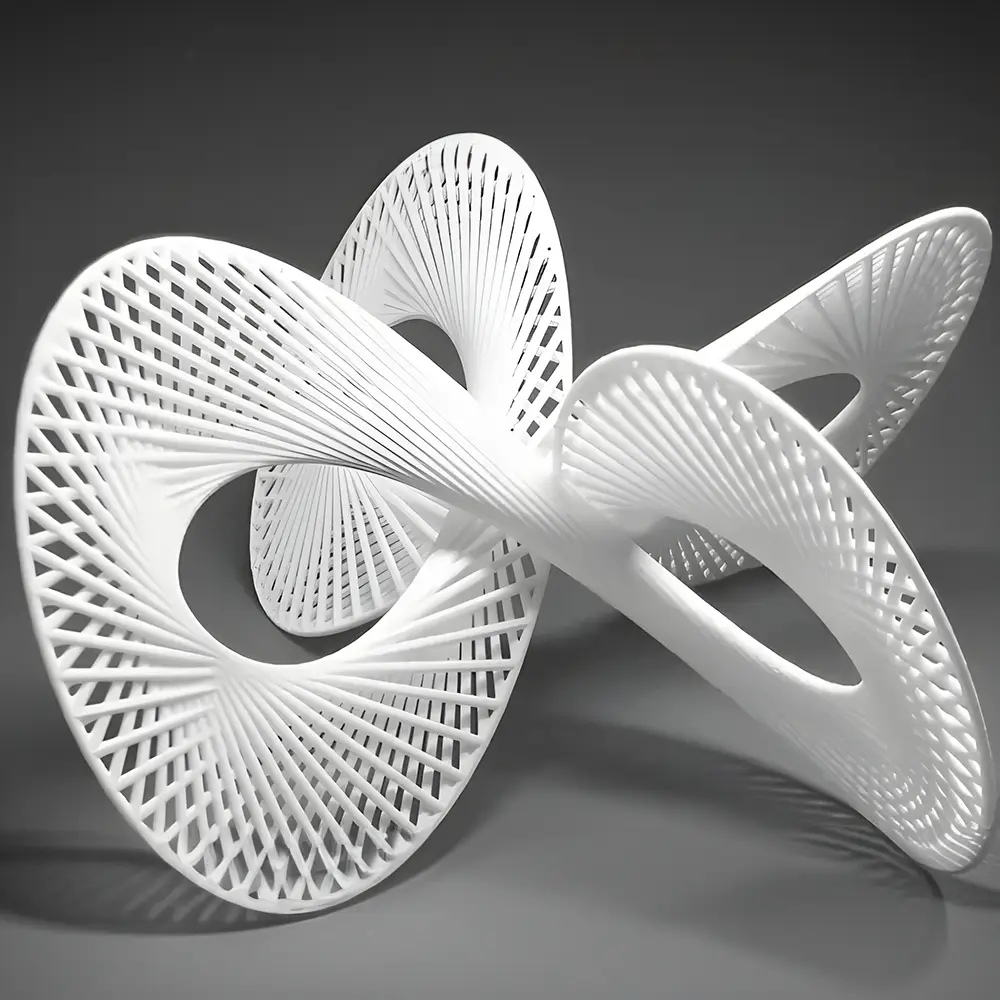

The Optima Series Industrial SLA 3D printers by Lightcured Technologies are built for large-scale production, precision, and reliability. With advanced stereolithography and digital light processing technologies, these machines deliver high accuracy, fast build speeds, and consistent performance across long print runs.

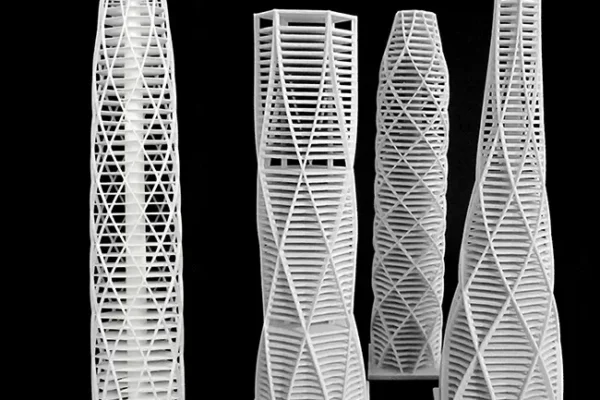

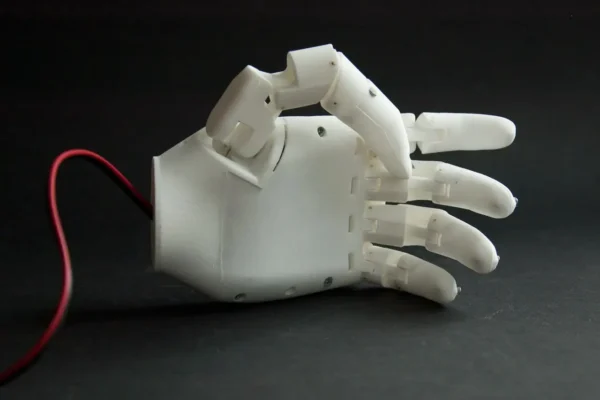

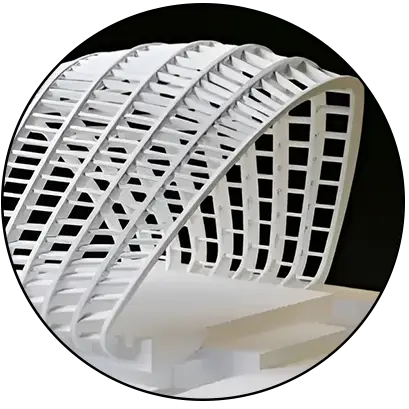

Designed for manufacturing, engineering, architecture, prop-making and large-format prototyping environments, industrial resin systems feature large build volumes, robust components, and automated process controls to ensure dependable results. They support a wide range of Monocure3D’s specialised resins, making them suitable for functional parts, investment casting patterns, and complex models that demand repeatable quality.

Whether producing one-off prototypes or full-scale production batches, our Optima industrial resin 3D printers provide the scale and performance needed to keep projects moving efficiently.

Built for Industry, Backed by Expertise

Scale with Confidence

Built for large-format printing, our SLA 3D printer range delivers production-ready capacity for industrial, engineering, and tooling applications.

Consistent Results

Laser level detection and precision optics ensure stable conditions and repeatable print quality across every build.

Robust Design

A heavy-duty frame, customised UV laser, and high-end galvanometer provide long-term reliability in demanding environments.

Expert Support

Backed by Australian-based service, training, and spare parts to keep your production running without interruption.

A Size to Suit Every Application

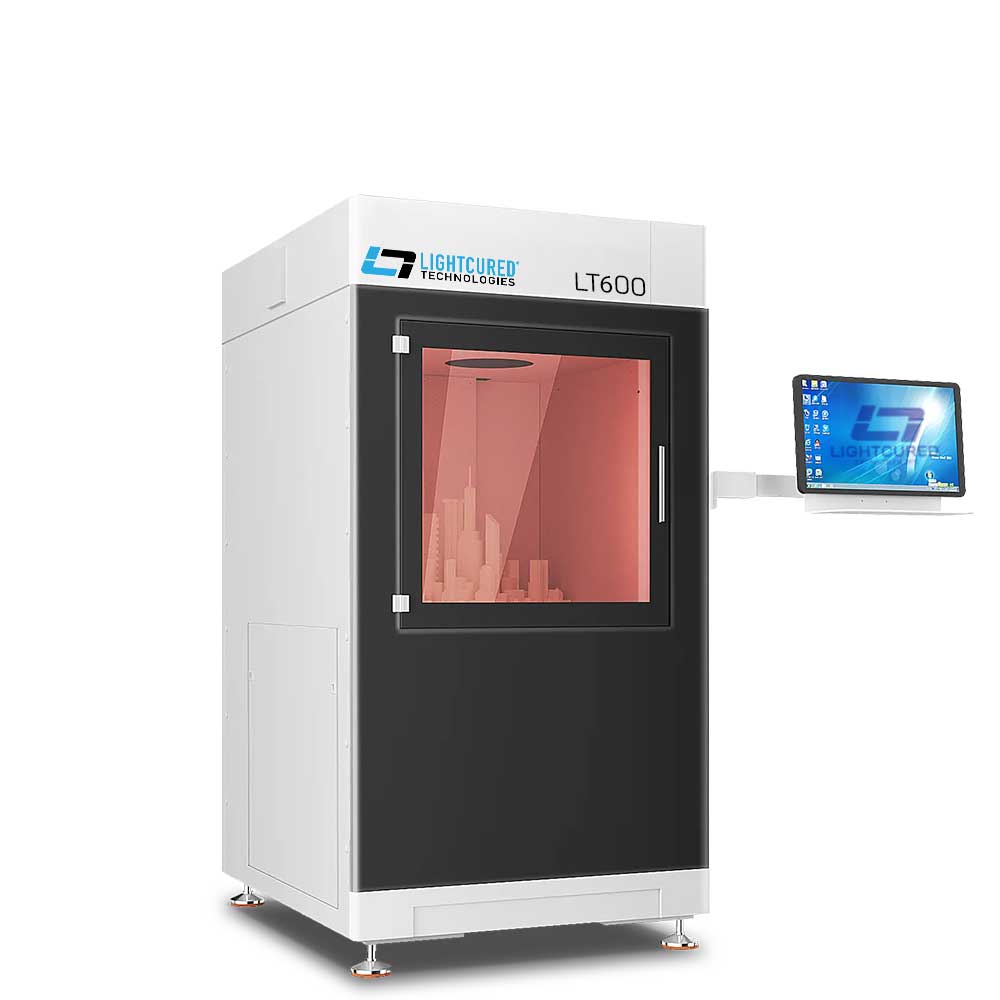

Optima LT600

Compact industrial SLA system designed for accuracy, reliability, and efficiency — the ideal solution for studios and service providers.

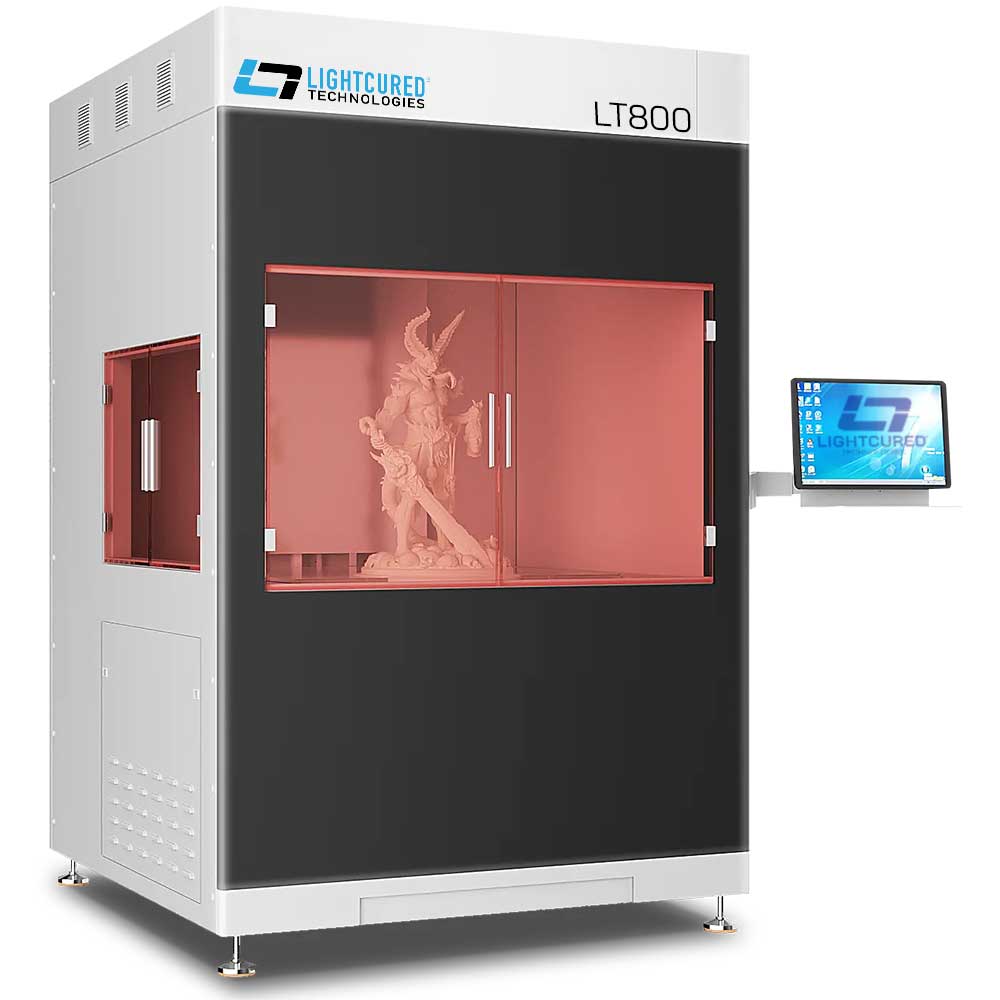

Optima LT800

A versatile SLA printer with a generous build volume, optimised for batch production and laboratory environments.

Optima LT1000

Industrial SLA printer tailored to your needs, offering scalable build sizes and reliable performance for high-volume output.

Optima LT1200

Purpose-built for oversized and specialised applications, delivering custom solutions for the most demanding projects.

Top-Down Technology Advantage

Large-Format Capacity

Handle oversized parts or multiple builds in one job with build volumes up to 1200 × 1200 × 600 mm.

Precision Laser Technology

Custom UV laser and galvanometer system delivers accuracy down to 0.1 mm.

Removable Resin Tank

Simplified removal and reduced finishing work accelerate your overall workflow.

Technical Summary

General specifications (applies across models)

| Specification | Range across models |

|---|---|

| 3D technology | Stereolithography (SLA), galvo scanning |

| Laser | UV laser (customised), high-end digital galvanometer |

| Resin compatibility | Photosensitive resin, 355–380 nm (Monocure3D) |

| Build volume | Up to 1200 × 600 × 500 mm (model dependent) |

| Layer thickness | 0.05–0.15 mm |

| Spot size | As small as 0.1 mm |

| Scanning speed | Up to 6000 mm/s |

| Printing speed | Up to 180 g/h |

| Liquid level detection | Laser level sensor |

| Resin tank | Removable and replaceable |

| Printing accuracy | Parts < 100 mm: L ± 0.1 mm; Parts ≥ 100 mm: L ± 0.1% × L |

| Power supply | 220 V, 50 Hz |

| Rated input power | Up to 650 W |

| Machine dimensions | Up to 1800 × 1300 × 2300 mm |

| Gross weight | Up to ~1500 kg (excludes materials) |

Frequently asked questions (FAQ)

Manufacturing, engineering, casting, architecture, and prop departments needing large-format output.

From compact industrial systems to large-format models, with volumes up to 1200 × 600 × 500 mm.

Yes. They are compatible with a wide range of Monocure3D engineering, industrial, and casting resins.

Yes. We provide installation guidance, on-site or remote training, and ongoing technical support to help you achieve consistent results.

The printers achieve a layer resolution of 0.05–0.15 mm, depending on the chosen settings and model.

The printers are custom built by our manufacturer and are usually ready within a few weeks. They are shipped via sea freight, and the delivery time depends on destination. Contact us for an estimated lead time to your region.

Yes. The printers are compatible with our AutoFILL system. AutoFILL can be customised to fit any printer with any sized pump, enabling fast, controlled filling without manual pouring.