Mini Resin | Translucent

Monocure3D Mini Resin Translucent is specifically designed for ultra-high detailed miniatures and scale models. With superior impact resistance and precision, this resin ensures stunning, durable results for all your intricate 3D printing projects. Mini Resin is 100% compatible with our exclusive CustomMix™ System.

Description

Monocure3D Mini Resin Translucent is designed specifically for 3D printing ultra-high-detail miniatures and scale models. This premium resin ensures superior impact resistance, making it ideal for intricate designs that are stunning and durable. Whether you’re crafting detailed figurines or precise scale models, Mini Resin Translucent delivers exceptional quality and reliability.

Key Features:

- Ultra-high detail for intricate designs.

- Superior impact resistance for enhanced durability.

- Optimised for 3D printing miniatures and scale models.

- Compatible with CustomMix™ System.

- Produces smooth surfaces and precise details.

Transform your 3D printing projects with Monocure3D Mini Resin Translucent. This high-performance resin is precisely engineered to deliver exceptional results for hobbyists and professionals. Perfect for creating miniature figurines, scale models, and intricate designs, it ensures durability without compromising on detail.

Available Colours: Tan and Translucent

Monocure3D Mini Resin is perfect for creating stunning, ultra-detailed miniatures and scale models. Engineered to combine great detail with exceptional durability, it’s the perfect choice for professionals and hobbyists alike.

Additional information

| Weight | N/A |

|---|---|

| Bottle Size Options | 0.5kg, 1kg, 5kg |

Explore Monocure3D Mini Resin

Monocure3D Mini Resin is the ultimate solution for creating highly detailed 3D printed models with exceptional durability. Developed explicitly for 3D printing miniature and tabletop figurines, scale hobby models, diorama terrain and custom collectable modes, this resin ensures a flawless finish that brings your creations to life.

Whether you’re 3D printing tabletop gaming miniatures or custom terrain, Monocure3D Mini Resin combines superior impact resistance with ultra-high detail. It’s optimised for MSLA 3D resin printers, making it an ideal choice for hobbyists and professionals.

Transform your creative vision into reality with Monocure3D Mini Resin — the ultimate resin for stunning, detailed designs durable enough to withstand drops and transportation.

Key Features of Mini Resin

Ultra High Detail

Capture every detail with precision and clarity, perfect for detailed miniatures and scale models.

Optimised for Miniatures

Designed specifically for 3D printing miniatures and scale models, delivering consistent, high-quality results.

Superior Durability

Engineered for impact resistance, ensuring your creations withstand handling and last longer.

CustomMix™ Compatibility

Enhance and customise your resin with our innovative CustomMix™ System for tailored results.

Mini Resin Applications

Miniature figurines, tabletop gaming models, scale hobby models, diorama terrain and components come to life with Monocure3D Mini Resin. Its versatility extends from figurines to custom collectible designs, ensuring exceptional results for professional and hobbyist creators. Whether 3D printing intricate figures for gaming or precise scale models, this resin delivers the quality, detail and durability you need to take your models to the next level.

Miniature Figurines

Tabletop Gaming Models

Scale Hobby Models

Diorama Components

Custom Collectibles

Custom Terrain

Mini Resin Printing Tips

Thorough Mixing

Shake the Mini Resin bottle thoroughly before each use to ensure a consistent mix of materials for optimal print quality.

Dial in Your Printer

Use calibration models to fine-tune your printer settings and achieve the best results with Mini Resin. Start with recommended

Support Placement

Always ensure supports are well positioned to maintain stability during printing. Use angled orientations to avoid flat surfaces sticking to the FEP film.

Post-Processing Care

Clean your printed models using ResinAway® or IPA, and post-cure them with a 405nm UV light to enhance durability and surface quality.

Mini Resin Printing Guide

Mini 3D Printing Resin offers exceptional versatility, supporting layer heights from 5 to 200 microns. For optimal results, models can be printed either solid or hollow. If printing hollow models, include drain holes to remove any trapped resin and prevent defects.

To minimise deformation caused by adhesion to the FEP film, orient large flat surfaces at an angle during printing. Incorporate dense, well-positioned supports for unsupported areas to ensure stability and detail accuracy.

This resin performs efficiently with a recommended 2-second normal layer exposure on most MSLA printers. Adjust your settings and use a calibration model to fine-tune your printer for our resin. For a starting point, refer to our printer settings page.

Stay informed with the latest tips and updates from the M3D team by subscribing to our ProTips Channel.

Mini™ Resin Finishing Tips

For best results with Monocure3D Mini Resin, follow these post-processing steps to ensure optimal quality, longevity and durability:

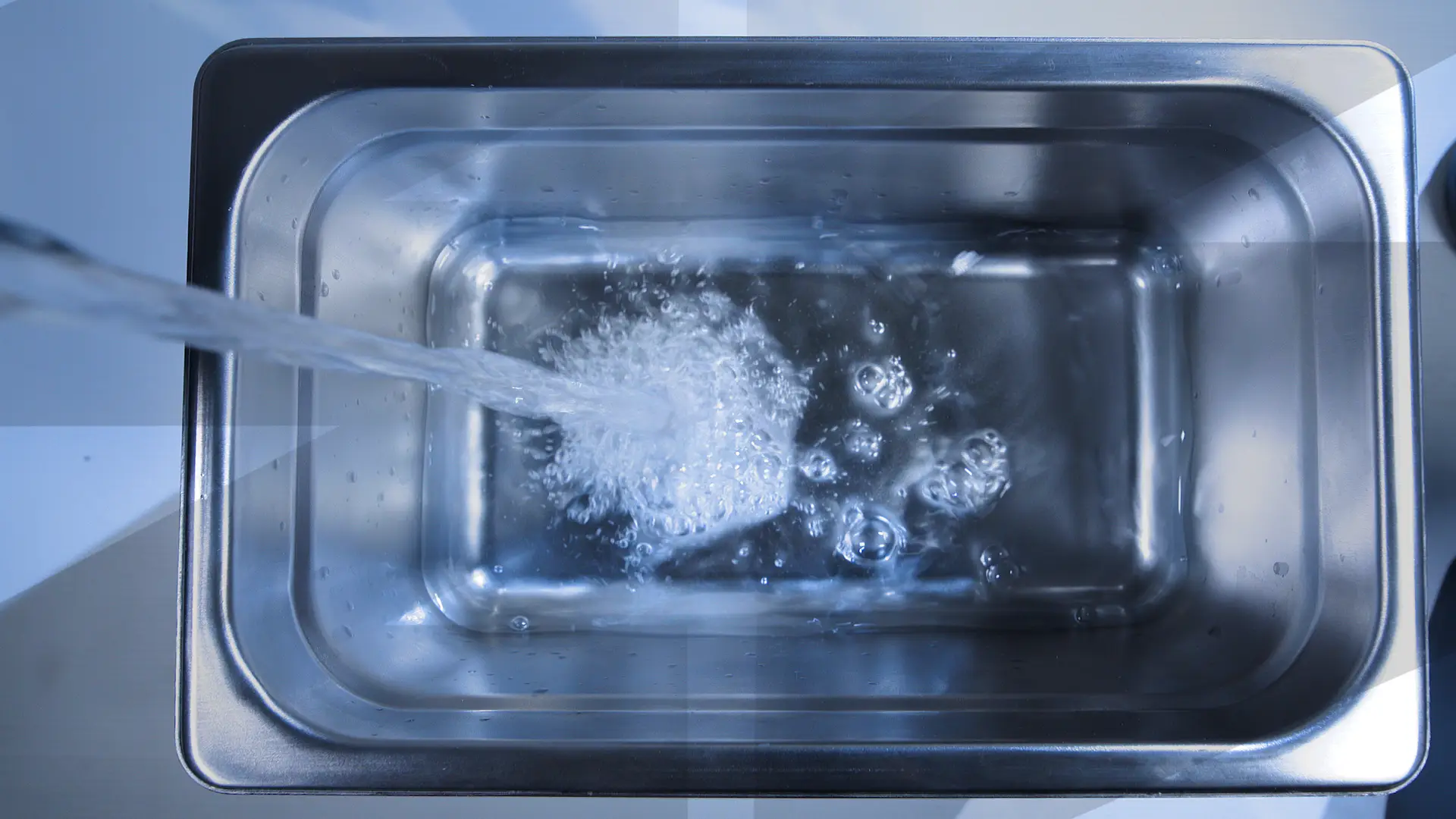

1. Pre-Wash: Use ResinAway® to remove uncured resin from the printed part. Start with a container filled with ResinAway® and gently scrub with a soft brush to remove the excess resin.

2. Final Wash: For finer details, place the part in an ultrasonic cleaner with ResinAway® for 3-5 minutes to dislodge any trapped resin.

3. Drying: Thoroughly dry the part using compressed air or lint-free cloth before post-curing. Avoid leaving excess IPA or ResinAway® on the surface, which can lead to cracking.

4. Post-Curing: Mini Resin requires post-curing to achieve its final mechanical properties:

- Use a 405nm LED Ultraviolet light to cure the model.

- Begin with a few minutes of curing, then rinse any remaining ResinAway® with fresh water.

- Return the model to the curing chamber for at least 30 – 60 mins to enhance tensile strength.

- Note: Mechanical properties will continue to improve over a few days after curing.

5. Finishing Touches (Optional): To protect and enhance your prints:

- Apply paint or clear varnish to shield the part from external elements.

- Components can be machined, sanded, or polished for a tough, scratch-resistant finish.

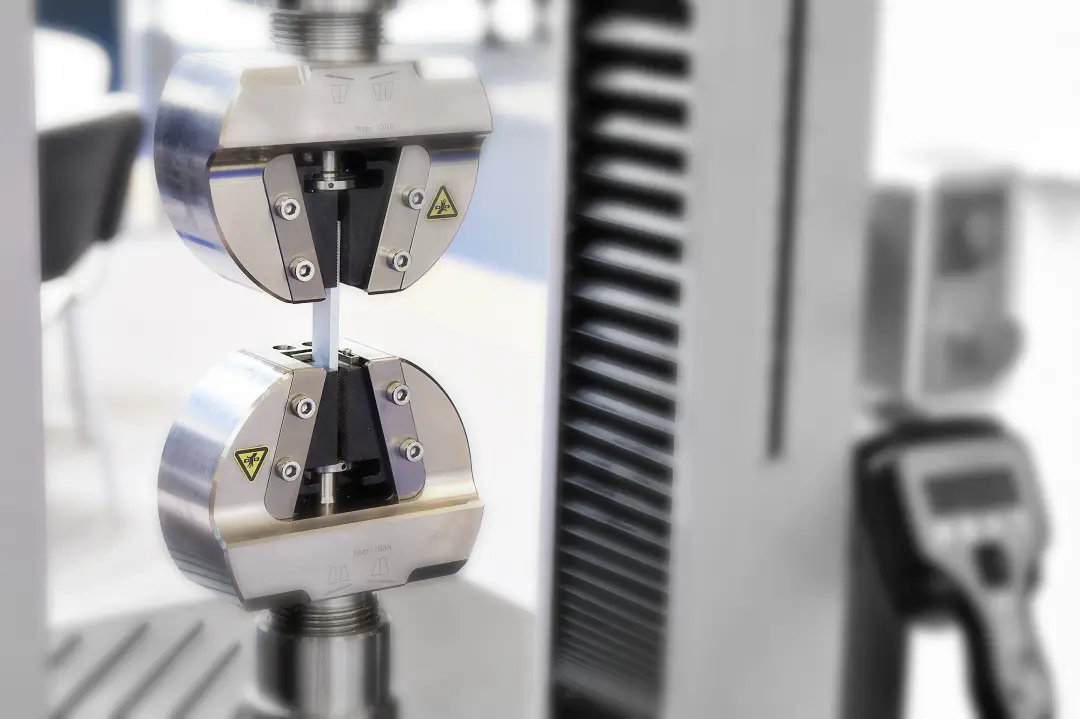

MINI™ MECHANICAL PROPERTIES

Method Code: ASTM D638-14

Product: Monocure3D MINI™ Resin (50μm)

Acceptance Code: Supply Findings

Specimen Type: Rectangular beam samples (Type IV)

Equip’ Serial No: UTM Serial No. 075

Conditioning: Tested at Ambient Temperature

SKUs

M/MINI-4109T, M/MINI-4163TR

Cross-Sectional Area (mm2)

26.47

Max Force (kN)

1.64

Tensile Strength (MPa)

62

Elongation at Break

6

Young’s Modulus (GPa)

0.8

Flexural Band Span (mm)

86.23

Max Load Applied (N)

380

Flexural Stress (MPa)

348

Shore Hardness (D)

94

Heat Deflection Temp

69°C @ 0.45MPa

MINI™ LIQUID PROPERTIES

Product Code(s)

M/MINI-4109T, M/MINI-4163TR

Viscosity

400 cps @ 25°C (Brookfield RVT)

Odour

Negligible Characteristic

Active Solids

100%

Shelf Life

36 months

UV Cure

405 nm (optimal)

Particle Size

< 10μm

Cure Speed

2-3 seconds

Storage

Dark cool, dry place

Wash Up

RESINAWAY® or IPA