TRAY Biocompatible Dental Resin

TRAY Biocompatible Dental Resin

Our TRAY Biocompatible Dental Resin is a high-performance, ARTG-certified (Class I) 3D printing material specifically designed to produce custom impression trays directly. Engineered for speed and accuracy, this resin is ideal for creating tailored trays used in various dental procedures, including implants, dentures, crowns, and bridges.

Read the Full Product Description Below.

Description

Monocure3Ds TRAY Bio-Compatible Dental Resin – Your Precision Partner for Custom Impressions

Our TRAY Biocompatible Dental Resin is a high-performance, ARTG-registered (Class I) 3D-printing material designed to produce custom impression trays directly. Engineered for speed and accuracy, this resin is ideal for creating tailored trays used in various dental procedures, including implants, dentures, crowns, and bridges, while maintaining the quality and affordability you expect from the all-Australian Monocure3D.

- Custom Impression Trays for Implants: Create precise, custom trays that ensure accurate implant placement.

- Denture Fabrication: Produce durable custom trays for denture impressions, improving patient satisfaction.

- Crowns and Bridges: Ensure optimal fit and accuracy with custom trays designed for precision.

- Fast and Efficient Printing: TRAY Biocompatible Dental Resin can print at 150-micron layer heights, significantly reducing printing time and allowing you to complete full impression trays quickly and efficiently. This speed saves time and enhances productivity in busy dental labs.

- Exceptional Strength and Durability: Custom TRAY Resin is formulated to withstand the forces involved in taking patient impressions and removing trays from the oral cavity. It maintains structural integrity even at thin cross-sections (minimum 2mm thickness recommended), ensuring reliable performance without the risk of breakage.

- Consistent and Accurate Impressions: Digitally manufactured trays offer consistency and accuracy that are hard to achieve with traditional methods. This ensures high-quality results, leading to better-fitting dental appliances and improved patient outcomes.

- Compatibility with Various Materials: Whether used with compound waxes, border moulding materials, or standard impression materials, this resin ensures excellent adhesion and compatibility, making it a versatile choice for any dental practice.

- Eliminates the Need for Preliminary Casting: Skip the stone model stage to save time and resources. Our TRAY Resin allows direct printing of the final impression tray, streamlining your workflow and reducing labour costs.

- Solid Aqua Colour: Our TRAY Biocompatible Dental Resin‘s distinctive solid aqua colour provides excellent visibility during impression-taking, enabling easy identification of details and ensuring precision. This colour also helps reduce eye strain during extended use, making it an ideal choice for dental professionals.

Key Features

Optimised for High Throughput: Designed to handle the demands of a busy dental lab, TRAY Biocompatible Dental Resin enables high-speed production without sacrificing quality.

Bio-Compatible Class I Certified: This transparent resin is certified as a biocompatible Class I material, meeting stringent safety standards for intraoral use.

Odourless and Tasteless: The resin is odourless and tasteless, ensuring patient comfort and making it ideal for intraoral applications.

High Heat Resistance & Sterilisable: TRAY Biocompatible Dental Resin is highly heat resistant and can be sterilised using standard autoclave protocols, maintaining hygiene and safety standards.

Two Tailored Formulas: This resin is available in two formulations for MSLA and DLP 3D printers, accommodating different technologies and ensuring compatibility and optimal performance.

Broad UV Range Compatibility: TRAY Biocompatible Dental Resin can be printed across a wide UV range of 365-405nm, providing versatility across printing settings and equipment.

Certified for Intraoral Use: Certified by the Australian Register of Therapeutic Goods (ARTG No. 398012), attesting to its suitability and safety for intraoral use.

Proudly Australian Made & Supported: All our resins are expertly developed and manufactured in Australia, embodying our commitment to high quality, consistency, and trust. Our experienced chemists ensure each product meets rigorous standards. Plus, with our Money-Back guarantee, you have the confidence to buy, try, and return if you are not completely satisfied. Experience the Monocure3D difference with every purchase.

Choose TRAY Biocompatible Dental Resin for reliable, fast, precise custom impression trays. With its balance of speed, strength, and biocompatibility, this resin ensures accurate results, helping you deliver optimal patient outcomes.

ARTG Certification: No. 398012

Additional information

| Weight | N/A |

|---|---|

| Resin Type | DLP, MSLA |

| Bottle Size Options | 1kg, 5kg |

Our Biocompatible Dental Range

TRAY Biocompatible Resin

TRAY Biocompatible Dental Resin is ideal for producing custom impression trays directly through 3D printing. Engineered for high-speed printing and durability, this resin ensures that trays maintain their structural integrity under impression-taking pressures. Its strength and precision make it well-suited for various dental applications, including implants, dentures, crowns, and bridges.

This resin is formulated to deliver consistent and accurate impressions, helping to reduce errors and improve outcomes in dental procedures. The solid aqua colour of the resin provides excellent visual contrast, ensuring that clinicians can easily see the details of the tray. Additionally, TRAY resin’s fast-curing properties enable laboratories and dental clinics to achieve higher throughput, minimising patient wait times and optimising efficiency. Designed with the modern dental professional in mind, TRAY resin strikes the perfect balance between performance and reliability.

This resin is available in two formulas for MSLA and DLP 3D printers. It can print within a wide range of UV, between 365 and 405nm. Monocure3D TRAY™ Dental Resin is approved for intraoral use by the Australian Register of Therapeutic Goods (ARTG) No. 398012

TRY-IN Biocompatible Resin

TRY-IN Biocompatible Dental Resin is a highly specialised material designed to simplify and improve the process of creating short-term trial dentures. This resin allows dental professionals to produce accurate, aesthetically pleasing try-in dentures that patients can evaluate during their fitting appointments. Its advanced formulation ensures precision and detail, enabling clinicians to confidently assess factors such as fit, occlusion, aesthetics, and phonetics.

In addition to its technical excellence, TRY-IN resin is easy to handle, streamlining workflows and reducing turnaround times. Its unique shading in off-white enhances the visibility of details without overwhelming the patient or the clinician. This resin is biocompatible and free from harmful compounds like MMA, BPA, and phthalates, ensuring patient safety. By providing cost-effective and efficient solutions, TRY-IN resin delivers outstanding results that benefit both the dental professional and the patient.

This resin is available in two formulas for MSLA and DLP 3D printers. It can print within a wide range of UV, between 365 and 405nm. Monocure3D TRY-IN™ Dental Resin is approved for intraoral use by the Australian Register of Therapeutic Goods (ARTG) No. 398012

GUIDE Biocompatible Resin

GUIDE Biocompatible Dental Resin is specifically formulated to create surgical guides that ensure precision and reliability in critical dental procedures. This resin provides outstanding dimensional accuracy and biocompatibility. It is suitable for guiding implant placements and other surgical interventions. Its robust heat resistance makes it compatible with most autoclave sterilizers, enhancing safety and hygiene. You can download our sterilization procedure here.

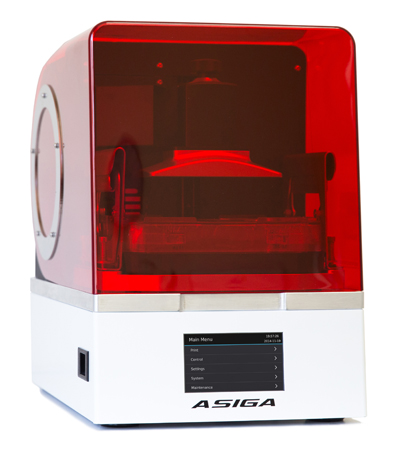

Designed for use with popular dental 3D printers—including Asiga, Sprintray DLP, and MSLA models like Phrozen, Prusa, Form4, and Uniformation—GUIDE resin is user-friendly and reliably produces guides that satisfy the rigorous standards of surgical applications. The resin’s capacity to retain its integrity during sterilization and handling ensures it is dependable for the most delicate and critical procedures. GUIDE resin combines practicality with advanced technology, providing dental professionals with a reliable solution for optimal patient outcomes.

This resin comes in two formulas compatible with MSLA and DLP 3D printers. It can print across a wide UV range, from 365 to 405nm. Monocure3D GUIDE Dental Resin is approved for intraoral use by the Australian Register of Therapeutic Goods (ARTG) No. 398012

The Benefits of Biocompatible Resin Technology

High Precision

These resins offer exceptional accuracy, enabling the creation of highly detailed and precise components and ensuring reliable performance in a wide range of dental and industrial applications.

Biocompatible

Our Biocompatible resin range has been Certified Class I by the ARTG. Once cleaned and post-cured, all our BIO resins are odourless and tasteless.

Autoclavable

Once cured, this material is suitable for sterilisation using standard autoclave protocols. The mechanical properties provide the ultimate strength for a variety of devices.

Multi-compatible formulas

It will work with all 3D resin printers. Choose the formula that is best suited to work with your DLP/MSLA 3D printer. Find your printer settings here.

Which Biocompatible Resin formula Suits your 3D Printer?

All our Biocompatible Dental Resins are available in two formulas. Since DLP printers output more power than MSLA, we have a version to cover both system types.

Choose the DLP formula if your printer uses a projector module (DLP) to expose the layers. These include brands and models such as the MoonRay, SprintRay, Peopoly Moai, Asiga UV-Max & Pro 4K, Phrozen Make, B9 Creator, Flashforge Hunter, XYZ Nobel, and Kudo Titan.

If your 3D printer uses an LCD screen and a LED array (MSLA) to expose the layers, you must use our regular MSLA formula. These include Anycubic, Phrozen, Creality, Elegoo, Epax, Peopoly, Prusa, Uniz, Wanhao, WOW SparkMaker & Kelant.

If your printer is not listed here, please Contact Us.

Expert Advice for Biocompatible Resin Printing

Position the model on the build plate so that no support structures are generated on its soft tissue-facing surfaces.

Check our printer setting page to see if we have your printer listed to give you a good starting point. To ensure the most accurate results, we suggest you dial-in new resins using a calibration model.

Try to position the occlusal surfaces away from the build plate to auto-generate the placement of support structures. You can add or remove supports where necessary.

It is recommended to duplicate as many Models that fit within the build plate size to ensure you have spares in case of print or processing failures.

7 Step Guide to Post-Processing

For best results after printing, use ResinAway® to remove uncured resin from the part. It cleans faster, better and lasts longer than IPA. It is non-flammable, doesn’t evaporate and has a pleasant scent. Follow the steps below to achieve the best finish for your 3D Printed dental models.

1. Use a pre-wash container of Monocure 3D ResinAway® and a soft brush to clean off the uncured resin.

2. Place the model in an ultrasonic cleaner filled with ResinAway® for 3-5 minutes. It’s recommended to angle the model’s occlusal surfaces down so the resin can fall away as it is agitated.

PROTIP: The 3D model should not be left for longer than 10 minutes in any cleaning solution to avoid micro-cracks and splitting.

3. Once cleaned, dry the print with compressed air. If any particles or residue are still present on the model, rinse, dry, and repeat until any uncured resin is removed.

4. Before post-curing, using a side cutter, trim supports as close to the point of attachment to the surgical guide as possible.

5. The surgical guide must be post-cured before use. It is recommended minimum post-cure time is between 15-25 minutes, depending on the specification of your curing unit.

6. To ensure a smooth surface finish, take a small file and sand away small nubs left over by the support structure. Once finished, use high grit sandpaper to blend the sanded areas.

7. Sterilise printed dental surgical guide parts in an autoclave after thorough washing, drying, post-curing, and assembly.

PHYSICAL PROPERTIES (MSLA)

SKUs

M/BIOD-5001AQ, M/BIOM-5002AQ, M/BIOD-3990C, M/BIOM-4002C, M/BIOD-4086A1, M/BIOD-4088A3, M/BIOD-4089A4, M/BIOD-4090BL, M/BIOD-4113A2, M/BIOM-4086A1, M/BIOM-4088A3, M/BIOM-4089A4, M/BIOM-4090BL, M/BIOM-4113A2

Colour(s)

Transparent, Aqua, A1, A2, A3, A4, BL

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Very Low Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1.5-3 seconds per layer

Storage

Dark, cool & dry place

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible MSLA Printers

- Anycubic

- Phrozen

- Creality

- Elegoo

- Epax

- Peopoly

- Prusa

- Uniz

- Wanhao

- WOW SparkMaker

- Kelant

- Not Listed – Contact Us

PHYSICAL PROPERTIES (DLP)

SKUs

M/BIOD-5001AQ, M/BIOM-5002AQ, M/BIOD-3990C, M/BIOM-4002C, M/BIOD-4086A1, M/BIOD-4088A3, M/BIOD-4089A4, M/BIOD-4090BL, M/BIOD-4113A2, M/BIOM-4086A1, M/BIOM-4088A3, M/BIOM-4089A4, M/BIOM-4090BL, M/BIOM-4113A2

Colour(s)

Transparent, Aqua, A1, A2, A3, A4, BL

Viscosity

500cps @ 25°C (BrookfieldRVT)

Odour

Negligible Characteristics

Shelf Life

36 months

Active Solids

100%

UV Cure

365nm to 405nm

Cure Speed

1-3 seconds per layer

Storage

Dark, cool & dry place.

Wash Up

RESINAWAY® or IPA (Isopropyl Alcohol)

Compatible Printers

- Asiga

- SprintRay

- Peopoly

- MoonRay

- Phrozen Make

- B9 Creator

- Flashforge Hunter

- XYZ Nobel

- Kudo Titan

- Not Listed – Contact Us

Are You Using Dental 3D Printer Resin in Your Work?

Are you interested in becoming a Monocure3D Reseller? Join our network of trusted partners by completing our Application Form, and we’ll be in touch to discuss the next steps.

Do you work in Education or government, or do you own a Business? Please complete our Wholesale Application Form to set up a wholesale account.

If you would like to discuss setting up payment terms, please contact us directly, and our team will be happy to assist you with finding a solution that works for your business.