Industrial DLP 3D Printer | DLP300

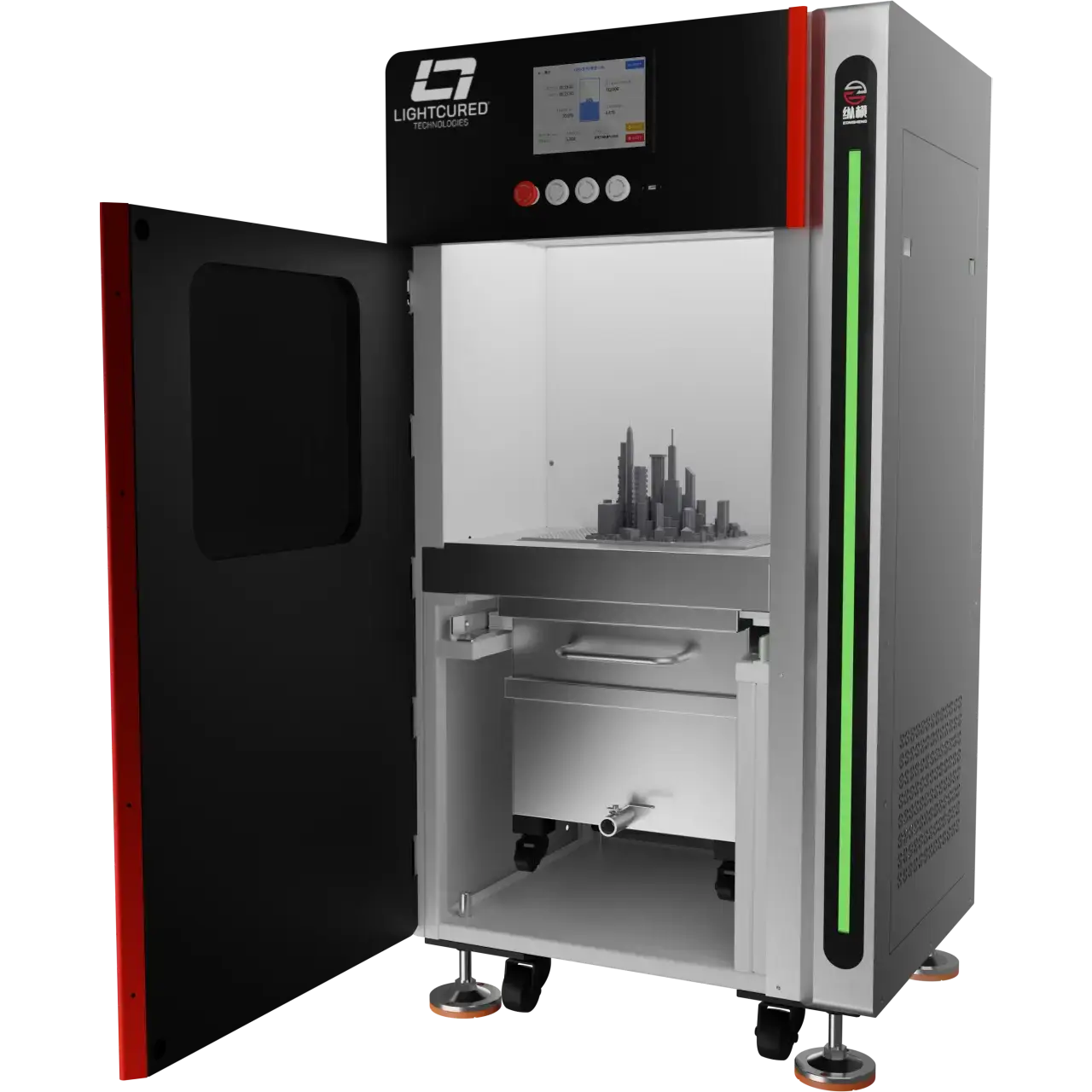

A versatile mid-size DLP printer offering higher build capacity for dental labs, jewellery manufacturers and engineering teams needing increased throughput and consistent surface quality.

For pricing and availability, please contact us here.

Description

Description

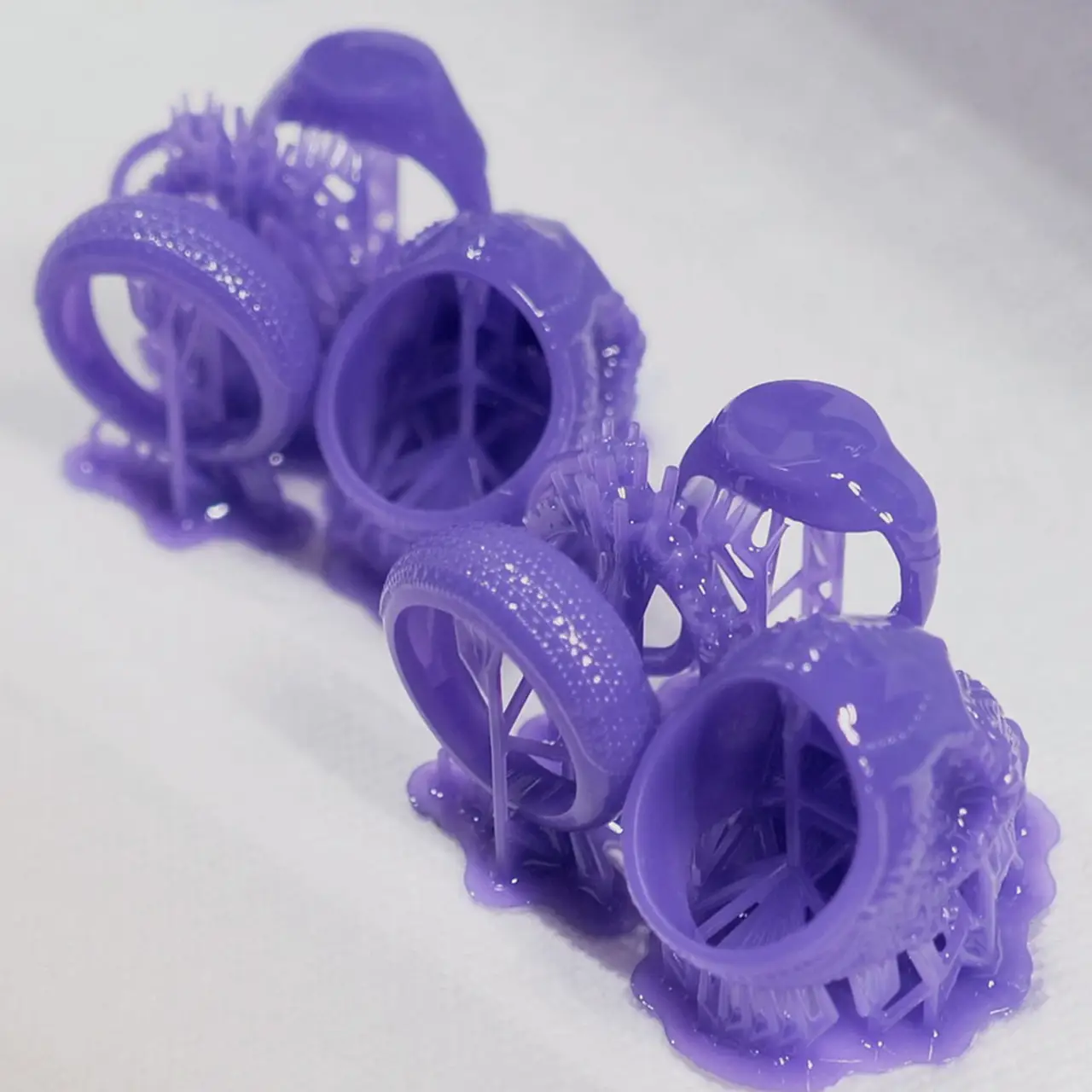

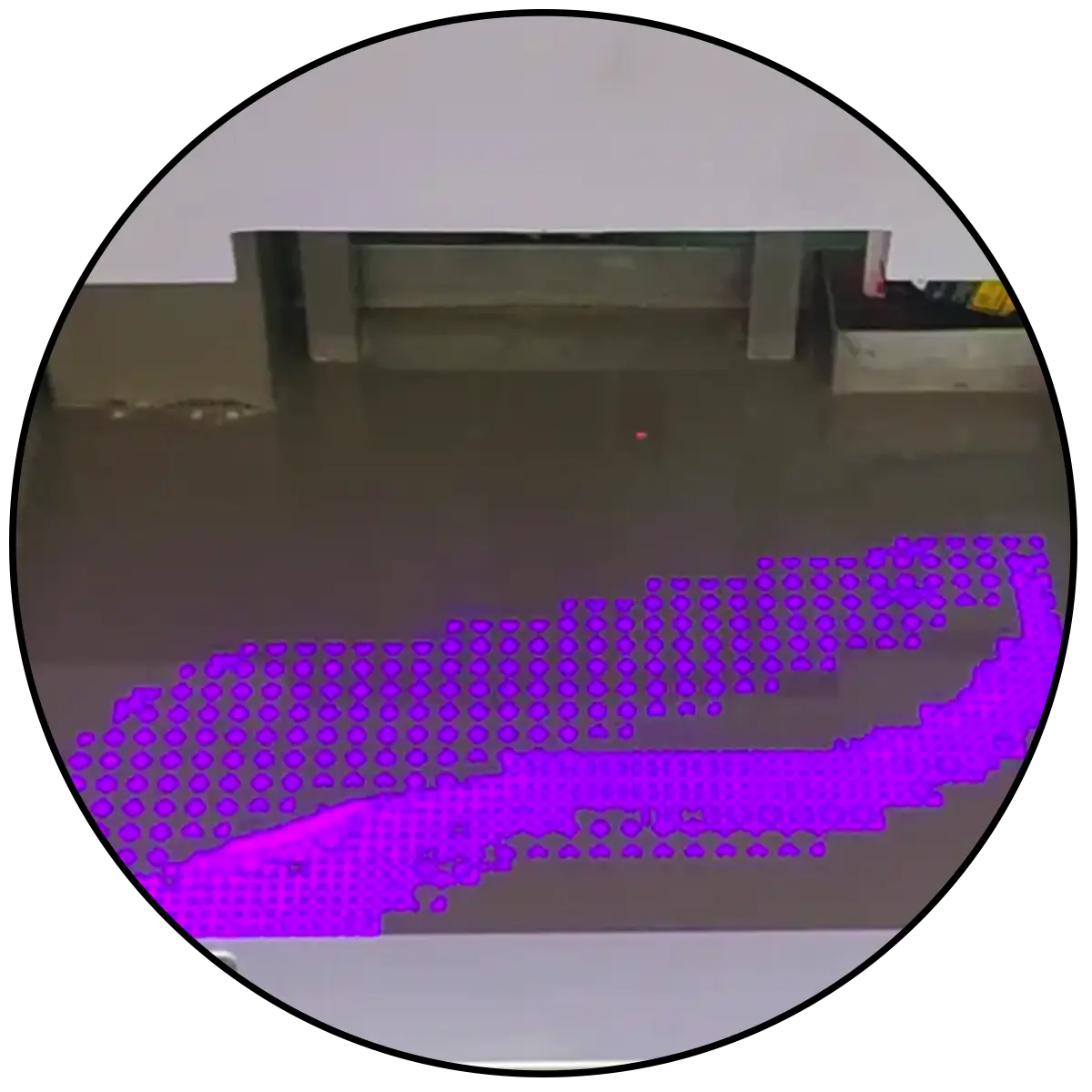

The DLP300 is a mid-size top-down DLP 3D printer that balances build capacity with high detail and repeatable accuracy. It is designed for dental laboratories, jewellery manufacturers and engineering teams that need reliable throughput without compromising surface quality. Full-layer projection cures each slice in a single exposure, helping maintain consistent results across the whole platform.

Built for daily production, the DLP300 supports a broad range of 405 nm resins and integrates well into existing digital workflows. Removable resin tanks, optional automatic model removal and AutoFILL compatibility support efficient resin management and reduced handling time.

Key features

- Mid-size top-down DLP printer for labs and production environments

- Single-exposure projection for accurate, repeatable layers

- Suitable for models, splints, patterns and engineering parts

- Supports multiple 405 nm Monocure3D resins for different applications

- Top-down process for reduced peel forces and stable print conditions

- Removable resin tank for straightforward cleaning and changeover

- Optional automatic model removal for more efficient part handling

- AutoFILL is compatible for automated resin filling and level control

Technical specifications

| Product model | DLP300 |

| 3D technology | Digital Light Processing (DLP), top-down |

| Light source | High-resolution industrial projector |

| Projection wavelength | 405 nm |

| Build format | 300 mm class platform for increased build capacity |

| Layer thickness | Typically 0.025–0.15 mm (material and settings dependent) |

| Pixel size | Fine pixel pitch for detailed anatomy and small features |

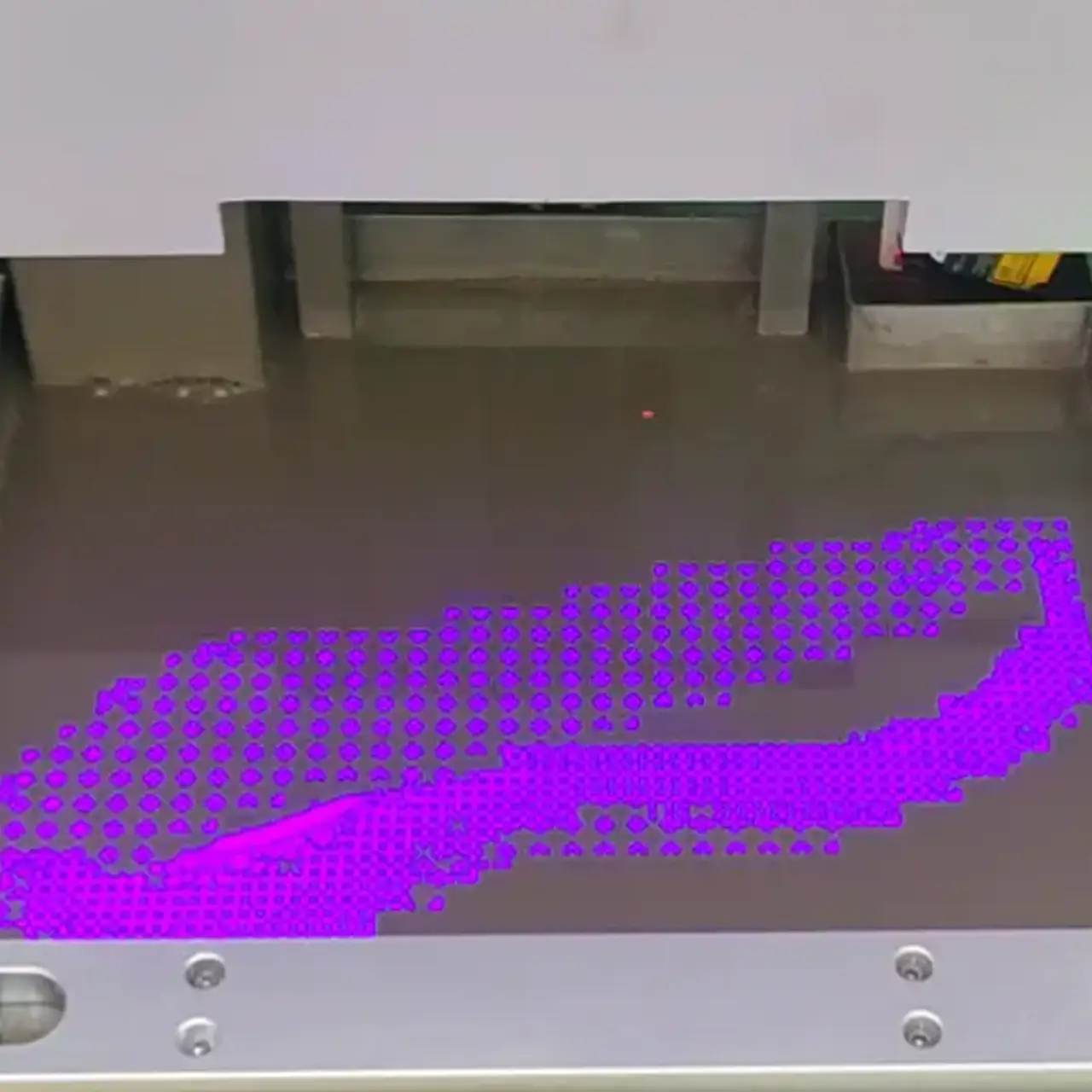

| Exposure mode | Single-exposure full-layer projection |

| Resin compatibility | 405 nm photosensitive resins including dental, jewellery, flexible and engineering grades |

| Resin tank | Removable tank for cleaning and material change |

| Automatic part removal | Optional automatic model removal system |

| Liquid level handling | Controlled resin depth for consistent exposure |

| AutoFILL compatibility | Compatible with AutoFILL, configurable for tank size and pump output |

| Power supply | 220 V, 50 Hz |

| Machine type | Industrial chassis for lab and production floor environments |

Dental | Jewellery | Prototyping | Education | Automotive | Aerospace | Manufacturing | Engineering

The Top-Down DLP Series 3D Printers

The DLP Series brings top-down Digital Light Processing technology to professional and industrial users who need consistent results, high accuracy and dependable long-term performance. This range is designed for applications where precision and efficiency matter, from dental production and jewellery casting patterns to rapid prototyping and short-run manufacturing.

The top-down structure provides excellent stability for larger, heavier models, and the entire layer is cured simultaneously with a high-resolution light engine. This approach supports fast print cycles with reliable dimensional accuracy across the whole build area. Each model in the DLP Series is built for continuous use, suited to automated workflows where printed parts are removed between jobs for uninterrupted production.

The DLP Series is compatible with a wide range of 405 nm resins, including dental, engineering and casting materials. It delivers an accurate, capable and cost-effective solution for businesses seeking a straightforward path into industrial DLP printing.

Built for Industry, Backed by Expertise

Scale with Confidence

Designed for compact production, the DLP Series offers efficient build volumes from 200 to 400 mm. The top-down DLP process delivers rapid print cycles, making these printers ideal for dental work, jewellery, prototyping, and small-format industrial applications.

Consistent Results

High-precision projection and controlled layer formation provide stable printing conditions across every job. The top-down architecture reduces peel forces, helping achieve smooth surfaces, sharp detail, and dependable accuracy.

Robust Design

A rigid chassis, refined light engine, and reliable motion system support day-to-day performance in busy lab and workshop environments. Components are engineered for long service life with minimal maintenance.

Expert Support

Supported by an Australian-based team providing guidance, training, and spare parts. We help you keep production moving smoothly whether you are running a single printer or managing a small fleet.

A Size to Suit Every Application

DLP200

The DLP200 is designed for accuracy, reliability, and speed. Its compact build area is well suited to smaller dental labs, orthodontic practices, jewellery workshops, and studios producing detailed components. It offers fast cycle times with minimal material use, making it a practical daily workhorse.

DLP300

The DLP300 provides a balanced platform for clinics and labs needing extra capacity without moving to a large-format machine. It supports a broader range of applications, including surgical guides, splints, models, and minor engineering parts. The top-down DLP process maintains consistent print quality throughout the entire build.

DLP400

The DLP400 is the largest model in the series and is built for higher throughput. It is ideal for busy dental labs, production environments, and specialist manufacturers handling multiple jobs each day. The increased build volume allows efficient batch printing while maintaining the accuracy and fine detail expected from a precision DLP system.

Top-Down Technology Advantage

DLP Precision

The projected light engine delivers sharp detail and smooth surfaces across every build. The top-down process keeps forces low, helping achieve consistent accuracy for crowns, bridges, models, and fine jewellery patterns.

Fast Production Cycles

Top-down DLP technology cures each layer quickly, allowing rapid print times even on detailed jobs. Ideal for labs and workshops needing reliable output throughout the day without slowing down workflow.

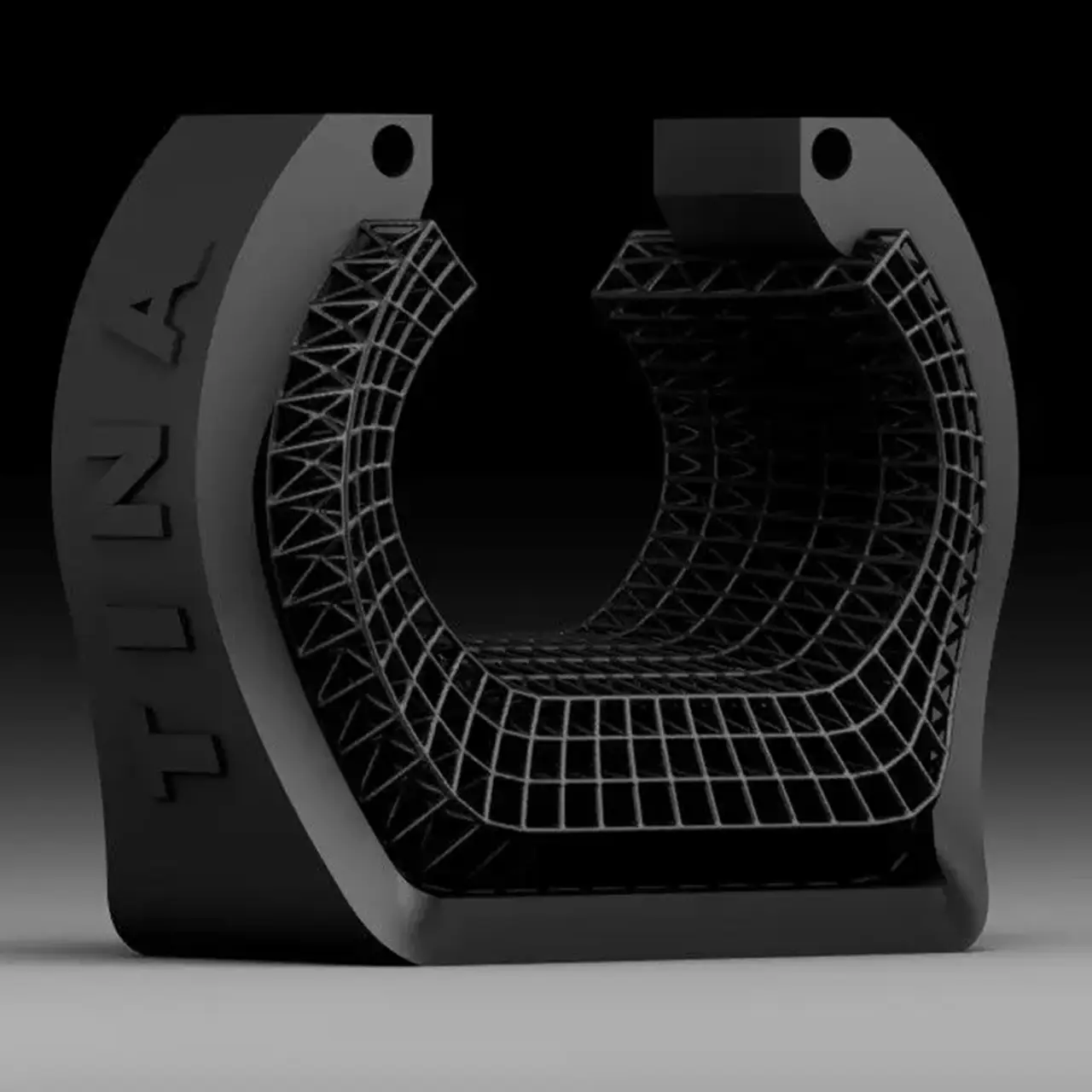

Automatic Model Removal

An optional auto-removal system lifts and clears completed prints as each job finishes. This keeps the build area free for the next run, reduces handling time, and supports continuous production in busy labs and workshops.

Technical Summary

| Specification | Range across models |

|---|---|

| 3D technology | Digital Light Processing (DLP), top-down projection |

| Light source | High-resolution industrial projector (4K, depending on model) |

| Resin compatibility | Photosensitive resin, 405 nm, including dental, jewellery, engineering, flexible and high-temperature materials |

| Build volume | Available in 200 mm, 300 mm and 400 mm formats, depending on model |

| Layer thickness | Typically 0.025–0.15 mm |

| Pixel size | As small as 35–50 microns depending on model |

| Exposure speed | Fast full-layer curing using single-exposure projection |

| Printing speed | Model-dependent, significantly faster than LCD or SLA for small and medium parts |

| Automatic part removal | An optional automatic model removal system is available across the DLP Series |

| Liquid level detection | Integrated resin level monitoring |

| Resin tank | Removable tank for easy cleaning and fast resin changes |

| Printing accuracy | High accuracy with pixel-defined projection and stabilised top-down curing |

| Power supply | 220 V, 50 Hz |

| Machine dimensions | Compact footprint across all DLP models, varies slightly with size |

| Gross weight | Varies by model |

Frequently asked questions (FAQ)

DLP systems excel in dental, jewellery, engineering prototypes, small-batch manufacturing, and any work that requires high detail and repeatable accuracy.

The projector cures each layer from above, while the build platform lowers into the resin. This reduces peel forces, allows faster printing and supports a wider range of resin types without stressing the model.

The DLP Series is available in 200, 300 and 400 mm formats so you can choose a system suitable for clinics, small labs or specialised production environments

A digital projector exposes a full layer in one shot, ensuring sharp pixel edges, stable geometry and consistent curing. This leads to smooth surfaces and excellent dimensional accuracy.

The printers support a wide range of Monocure3D resins, including dental, jewellery, engineering, flexible, transparent and high-temperature materials. Profiles can be customised to suit the application.

DLP can be significantly faster because each layer is cured in a single exposure. This makes the printers ideal for production environments where throughput matters.

Most users print comfortably between 25–100 microns depending on the model and task. The pixel-based projection ensures crisp results at all standard layer heights.

Yes, but usually fewer compared with bottom-up LCD systems. The top-down design reduces suction forces and helps create cleaner undersides and smoother surfaces.

Yes. The DLP Series is suitable for a wide range of dental resins designed for trays, models, guides, try-ins and castables. Always follow material curing guidelines.

Each printer includes a removable resin tank which makes switching resins quick and clean. Spare tanks can be kept for dedicated materials.

The printers are compatible with Voxeldance Tango and other supported slicers. Resin profiles can be adjusted to suit your workflow.

Yes. The printers can work with our AutoFILL system, which can be customised to suit any tank capacity. This allows fast, controlled refilling without manual pouring.

Regular checks of the resin tank, cleaning the projection window and keeping the linear rails clean are usually all that is needed. The machines are designed for reliable daily use.

The printers are built to order and usually completed within a few weeks. Shipping occurs via sea freight, and delivery time depends on your location.

Yes. We provide remote or on-site training and ongoing technical support to ensure you achieve consistent, reliable results.