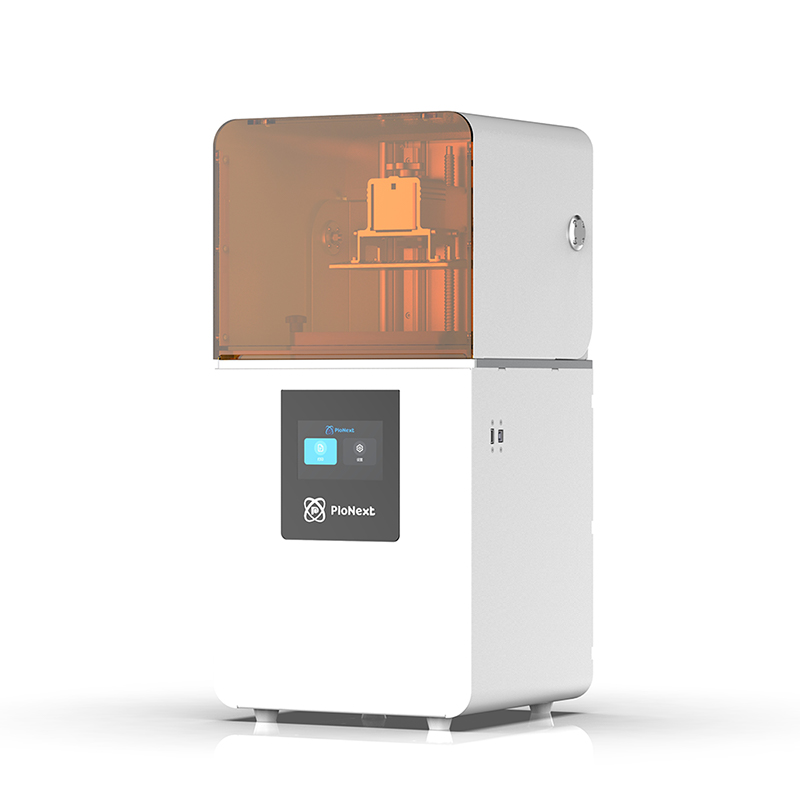

D150 is a DLP dental 3D printer that can freely adjust the light intensity. Could accomplish the printing tasks efficiently with adjustable light intensity: 6000-20000uw/c㎡. High-definition projection, stable Z-axis structure design, smoother model printing surface, and light engine providing up to 90% light uniformity. Print speed 60-80mm/h, 5″full-color touch screen, Print size 144×81×100mm.

D150 Specifications

| Third-Party Materials: | Yes | Rated power: | 35W | |

| File format: | STL, OBJ | Layer height: | 0.01-0.2mm | |

| Slicer Software: | PioNext Box | Printing Speed: | 40-60mm/h | |

| Input voltage: | 100-240V | XY axis accuracy: | 75μm | |

| light intensity: | 6000-20000uw/c㎡. | Dimensions: | 327×300×675mm | |

| Light source: | COB (wavelength 405nm) | Build Volume: | 144×81×100mm | |

| Touchscreen: | 5-inch color touchscreen | Weight: | 22.11KG |

D150 Settings

Try our UNICAL™ Calibration Model

If you’re trying Monocure 3D Resin for the first time or have just got a new printer, you’ll need to tweak your slicer settings to ensure perfect synergy between our resin and your printer.

The most efficient way to achieve this is by using a Calibration Model. These small, intricate models are quick to print. To calibrate your printer using the UNICAL™ Download the STL model here and for step-by-step instructions on how to use the UNICAL™ head to our 3D Calibration Model Page.