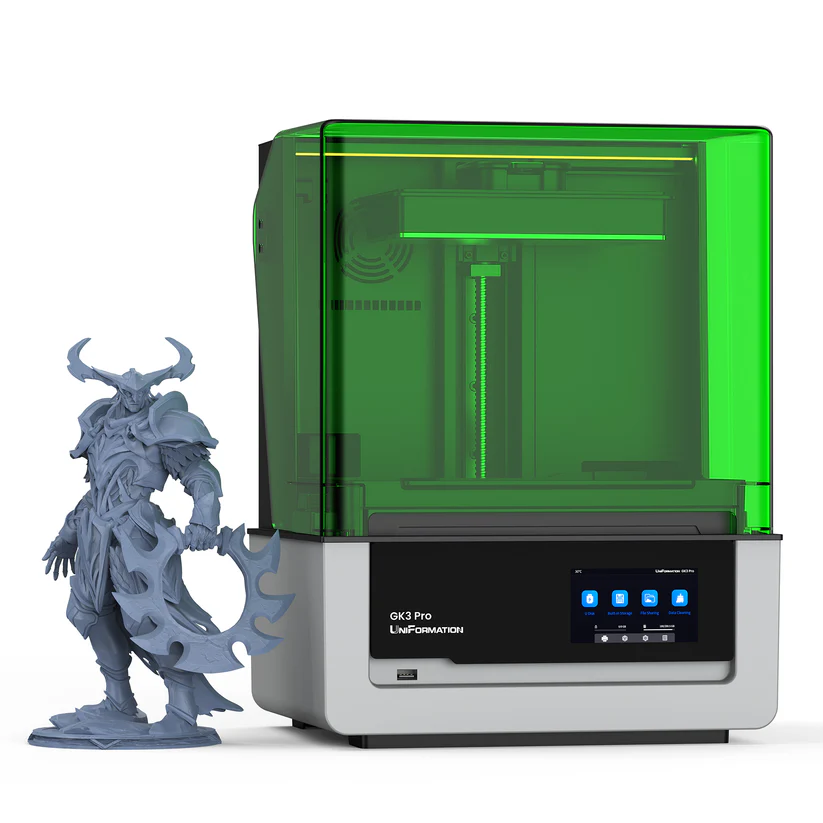

Introducing the GK3 Pro resin printer from Uniformation with a great size build volume, an auto-resin refill system and a heated chamber to ensure the best print quality.

Why choose Uniformation GK3 Pro Resin printer:

385nm UV light source

16K screen, 9.6 inch size screen

15 120 x 6 230 resolution

14 x 19 µm XY Axis Pixels

COB & Fresnel Collimating lens

Smart Resin feeding system

Automatic heating system

Built-in camera for smart monitoring

Uniformation Smart App

Quick-Release Design for the build plate and resin vat

Resin Drip Hanger Design

90° Rotational Touchscreen

GK3 Pro Specifications

| Third-Party Materials: | Yes | XY Resolution: | 14 x 19 μm | |

| Touchscreen: | 5-inch rotating capacitive touch screen ( 90° rotation) | Exposure time: | 2-3s/layer(0.05mm) | |

| Slicer Software: | UniFormation Slicer, Chitubox, Lychee Slicer | Release Film: | nFEP Film | |

| Connectivity: | Wi-Fi, Ethernet, USB | Power Requirements: | 110/220V | |

| Display type: | 16K 9.6-Inch Mono LCD Screen | Product Size: | 392 x 332 x 520 mm | |

| Wavelength Range | 385nm | Build Volume: | 211 x 118 x H240 mm | |

| Layer Height: | 0.03、0.05、0.1mm | Package Weight: | 24KG |

GK3 pro Settings

Try our UNICAL™ Calibration Model

If you’re trying Monocure 3D Resin for the first time or have just got a new printer, you’ll need to tweak your slicer settings to ensure perfect synergy between our resin and your printer.

The most efficient way to achieve this is by using a Calibration Model. These small, intricate models are quick to print. To calibrate your printer using the UNICAL™ Download the STL model here and for step-by-step instructions on how to use the UNICAL™ head to our 3D Calibration Model Page.