“Zortrax Inkspire is made for all applications where superior precision is of paramount importance. The human eye can’t see individual pixels when the image has more than 336 pixels per inch. Pixel density in models 3D printed on the Inkspire exceeds this value regardless of the viewing angle.”

Inkspire Specifications

| Third-Party Materials: | Yes | Pixel size: | 50 microns (0.05 mm) | |

| Operation: | 4″ IPS 800 x 480 | Layer Thickness: | 25, 50, 100 microns | |

| Slicer Software: | Chitubox, Z-SUITE | |||

| Connectivity: | Wi-Fi, Ethernet, USB | Power Requirements: | 110 V 1.4 A 50/60 Hz; 240 V 0.85 A 50/60 Hz | |

| Lightsource: | UV Integrated LED lights (wavelength 405nm) | Build Volume: | 132 x 74 x 175 mm (5.2 x 2.9 x 6.9 in) | |

| minimal layer height: | 25 microns |

Inkspire Settings

Try our UNICAL™ Calibration Model

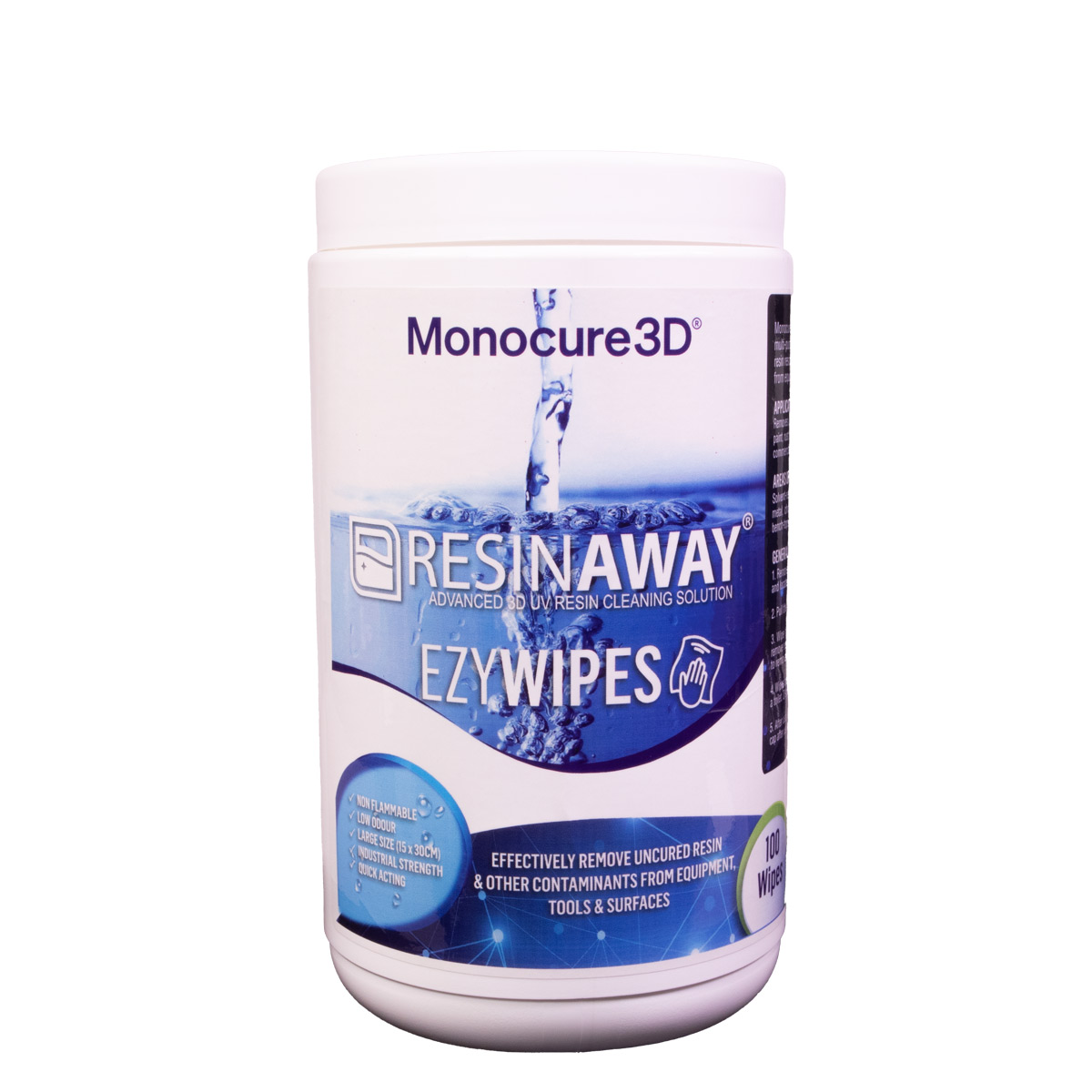

If you’re trying Monocure 3D Resin for the first time or have just got a new printer, you’ll need to tweak your slicer settings to ensure perfect synergy between our resin and your printer.

The most efficient way to achieve this is by using a Calibration Model. These small, intricate models are quick to print. To calibrate your printer using the UNICAL™ Download the STL model here and for step-by-step instructions on how to use the UNICAL™ head to our 3D Calibration Model Page.